Innovative Robotic Welding Systems

Yaskawa Motoman Robotics will showcase their Kinetiq Teaching technology and high-speed MS165 and MS210 robots at FABTECH 2015.

Posted: October 22, 2015

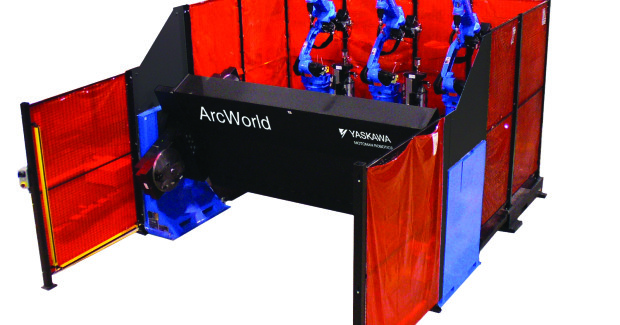

In Booth N-8020, Yaskawa America Inc. Motoman Robotics (Miamisburg, OH) will showcase their welding capabilities as they celebrate 100 years of automation with advanced technology and groundbreaking innovation that is seen in over 300,000 robots, 10 million servos and 18 million inverter drives they have installed throughout the world. On display will be a comprehensive line of welding robots, integrated power sources, torches and peripherals, and an extensive family of fully integrated ArcWorld welding cells, all providing reliable, low-risk solutions that deliver enhanced quality, productivity and ROI.

On display will be Kinetiq Teaching that enables job shops to easily implement robotic welding with simplified teaching and reduced set-up times by allowing operators to guide the robot by hand to desired weld positions. An icon-based menu is presented on the teach pendant’s color touch screen to allow the operator to define the task. Programming time is greatly reduced with the more intuitive manual positioning. The Graphic User Interface allows robot programming to be performed with minimal training. With Kinetiq Teaching, the welder moves the robotic welding tip next to a workpiece by physically hand-guiding the robot. Once the welding point is reached, the welder determines the welding parameters through a touch screen interface. After all the points are recorded, the welder can playback the programmed trajectory and modify it on-the-fly. By doing so, experienced welders will be able to set welding jobs and oversee the productivity of more than one robotic welder at a time, or train less skilled operators to program the welding robot and act as a technical adviser and a quality assurance resource.

Also on display will be the high-speed MS165 and MS210 robots that are 20 percent faster overall than previous ES-series robots and are designed to deliver unmatched performance and reliability in spot welding applications. The use of a gas spring and Sigma-5 motor technology result in a lighter weight and a reduced-profile design to allow higher robot density around a car body or a smaller workcell for Tier 1 applications. To increase cable life, enhance safety and reduce teaching time, the servo gun cables and air and water lines are routed through the robot’s base and upper arm to the wrist. The streamlined design enables the MS-series robots to reach into confined spaces. The MS165 and MS210 models have increased payloads of 165 kg and 210 kg, respectively. The high-speed spot and ARM (Advanced Robot Motion) control functions can provide up to 35 percent cycle time reduction and improve quality by providing consistent electrode force with optimum arm and gun motion control.

The newly redesigned ArcWorld® IV-6200SL “slim line” solution features dual MA1440 arc welding robots with controller, a high-speed ferris wheel positioner, integrated welding package, operator interface and a total safety environment. The slim line positioner reduces floor space requirements because the width of the positioner/workcell is only one meter wider than the fixture span. The safeguarding is designed to take advantage of the Functional Safety Unit in the controller to provide control reliable safety in accordance with the latest release of the Robot Safety Standard (ANSI/RIA R15.06-2012). The positioners feature the fastest indexing time in their class. The 755 kg payload version indexes in 2.25 seconds; the 1,255 kg payload version indexes in 3.25 seconds. The positioners utilize the MotoMount™ fixture mounting system. This patented design provides a flexible pivot to eliminate bearing stresses from fixture mis-alignment or unlevel floors and extends the life of the drives.

For shops with custom requirements, Yaskawa Motoman’s Automation Group can design advanced, innovative solutions.

Yaskawa America Inc. Motoman Robotics | Drives & Motion, 100 Automation Way, Miamisburg, OH 45342, 937-847-6200, www.motoman.com.