Increase Laser Cutting Parts Output Up to 400 Percent

Bystronic extends their BySprint Fiber laser cutting system portfolio by adding a 6 kW Fiber laser source for its 3015 and 4020 machine formats.

Posted: October 22, 2015

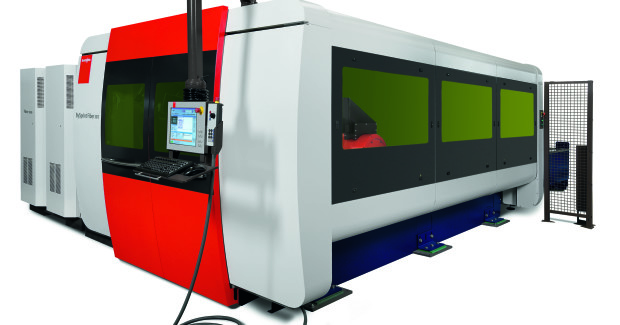

In Booth S-919, Bystronic Inc. (Elgin, IL) extends their BySprint Fiber laser cutting system portfolio by adding a 6 kW Fiber laser source for its 3015 and 4020 machine formats. The higher power considerably increases the BySprint Fiber’s cutting speed in the thin to medium range sheet metal thickness. A 6 kW Fiber laser cuts 1/8 in stainless steel up to 70 percent faster than a 4 kW Fiber laser. Its speed advantage is even more pronounced when compared to cutting the same material with a 6 kW CO2 laser source, where the 6 kW Fiber laser is three times faster. Depending on the type of material and the sheet thickness, parts output can be increased by up to 400 percent. The BySprint Fiber 4020 accommodates larger sheet sizes which deliver 78 percent additional cutting area and 78 percent larger part processing capability than the BySprint Fiber 3015. Equipped with a ByTrans Extended automated load/unload system, BySprint Fiber 3015 and 4020 models can generate highly productive and efficient job flows.

Also on display will be the new compact, ultra-high-speed Xpert 40 ergonomic press brake that is “moveable on demand” to where the shop needs it, when it is needed. Capable of 1,028 bends per hour, it is the fastest press brake of its size on the market and is also the first to offer integrated tool storage by combining entire setup and production from one single station, greatly reducing non-productive bending times. With its flexible tool selection and a press capacity of up to 44 US tons, Xpert 40 offers a wide range of applications from thin and thicker materials. A 6-axis ultra-high performance back gauge and high speed ram enable the cost-efficient production of highly complex shapes and ensures the highest process efficiency to keep pace with high speed Fiber lasers. High operator efficiency is also achieved through ergonomic design and individually adaptable workspace. Noteworthy is the process-controlled drive unit which reduces power consumption by up to 30 percent!

https://youtu.be/rmPcF-lAXwM

Bystronic Inc., 200 Airport Road, Elgin, IL 60123-9325, 847-214-0300, www.bystronicusa.com.