Documented Cost Savings for Abrasives

Rather than focusing only on energy savings or reducing costs associated with large equipment, manufacturers that are looking for potential savings in their plants should take the time to investigate just how much money they could save by switching out an abrasive. In doing so, they should evaluate fully how labor costs tie into the equation.

Posted: October 3, 2015

Demonstrating and documenting cost savings has become essential for today’s industrial suppliers and distributors as part of proving their solution offering to customers. This is especially important in the abrasive category, which consists of highly commoditized products. Most users don’t fully understand what separates one brand from the next. Manufacturers usually focus on cost per unit when presenting their products, rather than on how many total units are used or how those costs can tie up more time in labor-intensive operations.

Even when users accept the value proposition that time equals money, they may need hard numbers to be able to make the best decision. They can find this information in structured documented cost savings (DCS) programs, which compare the abrasive or tooling costs, time, and the labor shop rate related to a variety of abrasive products. DCS programs show end users conclusive evidence that superior products, which may have higher initial costs, can actually result in overall cost savings when all operational costs are taken into account.

Firm estimates, based on real data, help manufacturers see the bigger picture, including labor costs, instead of simply relying on the cost of the consumables alone. The approach also focuses on safety improvements that result from using higher quality abrasives, which also affects the end user’s productivity and bottom line. Documented cost savings programs should be backed by comparative tests, including those conducted in a laboratory setting, as well as in-field tests performed on the customer’s own equipment. In addition, the process should be administered by experts trained to carefully differentiate between cutting, grinding, and rust removal applications to ensure that the test results are meaningful while remaining customized for the individual end user’s specific application.

https://youtu.be/y0q4_zN6zQ8

FORMAL PROCESS NEEDED TO DOCUMENT VALUE

Documented cost savings programs are part of a larger movement towards providing value-added services such as process enhancements to the manufacturing industry. The notion is that customers are willing to acquire more expensive products and solutions when they recognize the long term value of what is offered. The idea behind documenting value is proving that your products and services are providing savings, while at the same time developing more of a partnership with the end user. [1]

As more value-documentation processes are being implemented by distributors and suppliers, and more customers are demanding them, those who aren’t providing this kind of documentation may be at a disadvantage. In today’s competitive environment, distributors and suppliers need to implement a much more formal process documenting the value they provide to customers. From the point of view of distributors, documented cost savings covers far more than just price – it includes delivery times, availability of products, and specialty resources that can help customers – even if the initial charge for the product might be higher. Leading distributors consider who they can have the best relationship with to provide a basket of goods with the highest overall value. This moves away from the cost of an individual item, say a grinding wheel, to the overall savings.

For example, our company long ago recognized the need to document our products’ cost savings. The earliest Productivity Analysis program, started more than 30 years ago, was originally designed as a simple method to demonstrate right on the shop floor why a grinding wheel priced at $3 was actually more cost effective than a competitive model priced at $2 per wheel. The approach relied on a live demonstration comparing removal rates, using the going labor rate to show labor savings from the use of the Walter wheel. Written documentation was negligible; results were noted on a piece of paper and given to the end user.

As the DCS movement evolved, we developed a three-step program to provide information important and relevant to the end user and centered on the end user’s plant and shop.

STEP ONE: BUCKET PROGRAM

About five years ago, the informal productivity analysis was transitioned into the Bucket Program, a deceptively simple, but formalized, documented cost savings approach. Rather than simply taking the word of a company representative on typical or average savings that could be made, a bucket is placed on the shop floor and customers are asked to discard all their used abrasives in the bucket. After a month, an expert performs a site analysis to visually analyze how the customer is using its abrasive products, note the challenges, and evaluate ways of saving the customer money. Recommendations are based on what is actually in the bucket – evaluators are able to explain where customers are literally throwing away money.

The analysis typically uncovers issues like flap disks that show evidence of improper wear or 5 in grinding wheels discarded when they are only worn to about 4 in, rather than the allowable 3 in. Glazed up or cut up or broken wheels could be indicative of the wrong product being used for a particular application or even reveal that operators are engaging in unsafe work practices. The Bucket Program offers a way to advise customers on equipment changes that could save them money in abrasive and tooling costs, wasted labor time and even lost man hours due to workplace accidents and injuries that are entirely preventable. One such example is by revealing instances in which the wheel being used is not right for the particular job.

New companion tools are being developed to enhance the program, including a mobile device app that systematizes the evaluation process and integrates it with report-writing software.

STEP 2: SAFETY SEMINARS

Safety seminars are offered to encourage a safer work environment, especially when the visual analysis shows a great deal of broken product in the bucket. Cut-off wheels are quite prone to breakage, which poses serious safety issues. Grinding wheels are turning at about 180 mph right in front of an operator’s face; they are usually the most dangerous product in the plant, and some plants even forbid use of cutting wheels because they are perceived as too dangerous when used improperly. The seminar includes operator training on the proper use of cut-off wheels to prevent injuries, another way to increase productivity and save money due to the associated health and legal costs in addition to lost man-hours.

STEP 3: PRODUCTIVITY PROGRAM

Customers want and need specific validation that any new products adopted will work in their shop, with their grinder and their personnel. This need has led directly to the third aspect of the approach, known as the Productivity Program. The Productivity Program is a personalized performance analysis of a Walter abrasive product versus the end user’s incumbent product in an industrial environment. The program tools determine exactly how much money end users can save annually when using products with longer life and higher productivity. A written Productivity Report is generated and can be sent to the end user by email for easy sharing.

With a database of brands available, the Productivity Program begins with an analysis of the removal rate of the particular brand versus the Walter product. Based on the use of Walter’s own grinder, the database contains information on the pressure/amperage draw put on the grinder. The grinding wheel, cutting wheel, or wire brush’s performance is measured, as is the time taken for the task to be completed compared to the competitive product.

This data is used in conjunction with laboratory testing to prepare a preliminary report showing savings when all other operation costs are taken into consideration. For example, if the Walter product is priced ten percent higher but lasts twice as long, cost savings are usually achieved. Similarly, if a process takes 15 minutes to complete with a competitor’s wheel and ten with a Walter wheel, labor time savings can be achieved. The program applies shop labor rates and develops a projection of overall financial impact.

However, a customer who gets a lab test with results of one product and one operator will not usually be convinced to make a change when they have 30 operators and a variety of equipment. So the process continues with experts taking the laboratory information back to the shop to conduct testing on the customer’s own equipment with their own operators to provide more realistic projections tailored to each individual end user.

The customer usually conducts their own broader scale tests so they can see the results for themselves. This is especially important with grinding wheels and abrasives, where the type of grinder can change the results dramatically. The more powerful the grinder, the more pressure an operator may put on the wheels, so customers typically want to do their own tests to see how different grinders and different operators affect the testing process. For example, a larger shop may use air grinders, so the Productivity Program laboratory analysis will be performed on an air grinder to give the shop a value proposition. If the shop uses an electric grinder (typical for smaller shops) the program conducts two tests – one with the user’s grinder, and one with a Walter or different type of grinder. This allows the report to include information on what the shop could save if they invested in a more powerful grinder.

The Productivity Program is generally offered with a “Money Maker” guarantee – the end user will not pay any more for the wheel than the product they are currently using. If the wheels have not generated the difference in savings at the end of the test period, they are given free wheels or a credit to make up the difference to minimize the risk of trying a new product.

PARTNERSHIP IN PRODUCTIVITY BLENDS APPROACHES INTO A COHESIVE WHOLE

The three-step DCS approach is blended together into the Partnership in Productivity program. The program is provided as a technical service to improve a customer’s profitability and demonstrate the importance of the relationship with the end user.

The DCS aspect delves deeply into a customer’s operations to include safety training, as well as recommendations on better ways to do the job. Changes may be recommended to make a process more efficient; for example, reducing the number of steps needed to achieve the desired surface finish. This can decrease the amount of time it takes to complete a job by minutes or even hours. The total cost savings from recommended process changes are presented in an all-inclusive document, with detailed information on savings in all areas. Each document is customized for the individual shop, including the specific grinding wheel used, grinder consumption, hours used, and information about injuries from grinding-related accidents.

The program uses knowledge from a technical representative who may visit as many as 30 different plant locations in a week. The technical specialist who is exposed to different ways of applying a product is much more likely to be able to present information on improvements and cost savings than manufacturing engineers employed in the same plant doing the same process for the same application every day. The specialist can survey the plant and put together recommendations that incorporate best practices from a wide variety of manufacturing processes.

While all three steps are available, the program can also operate in “bolt on” fashion. All customers take advantage of the core process, while larger customers may opt for safety training, and even larger customers make more use of the productivity aspect. The largest customers may be most likely to achieve major savings from recommendations that enhance the production process.

SAVINGS: SEEING IS BELIEVING

Surface technology products and solutions for the performance end of the market cover a diverse array of industries and applications, from tanks for micro-breweries to automobile assembly lines to food processing. Every supplier that wants to have staying power and be competitive globally has to do whatever it can to take costs out of its operation while maintaining and even improving quality and productivity. Looking for savings is part of everyone’s DNA, and companies are far more sensitive to supply costs than in days gone by.

Shown below are four examples that represent the range of companies participating in the Partnership for Productivity – large, medium, and small – and a range of industry types. Each example is unique to that company, but the results are typical.

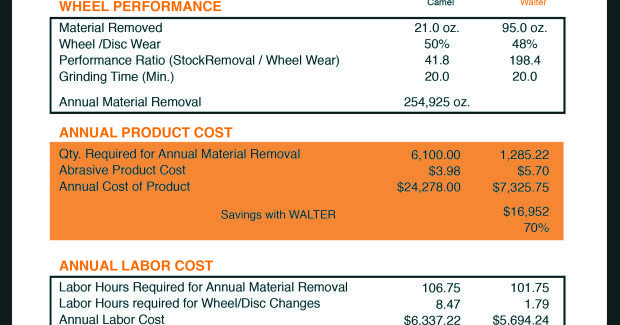

One of the world’s largest heating, ventilation and air conditioning (HVAC) companies was looking for a better aluminum grinding solution for its Colorado plant, one that would allow them to work faster and save money. As shown on Figure 1, the productivity analysis revealed that Walter’s Flexcut, a flexible grinding wheel that excels on aluminum, removed almost 350 percent more material over the same time period as the incumbent product. This allowed the company to work faster, reduce its inventory, and ultimately cut their grinding costs by 57 percent.

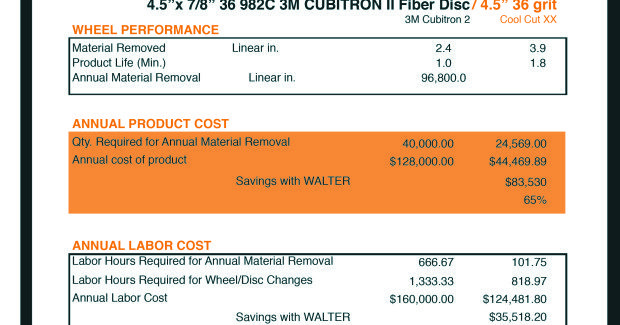

Another example is a prominent boat manufacturer located in Wisconsin that had been using sanding discs from another manufacturer. The comparative test showed that the Walter product provides 60 percent more material removal and lasts 50 percent longer than the incumbent product. This resulted in decreased inventory, a quicker work process, and total process savings of nearly 40 percent. The customer achieved an annual savings of more than $119,000. Figure 2 shows the calculations provided by the productivity analysis.

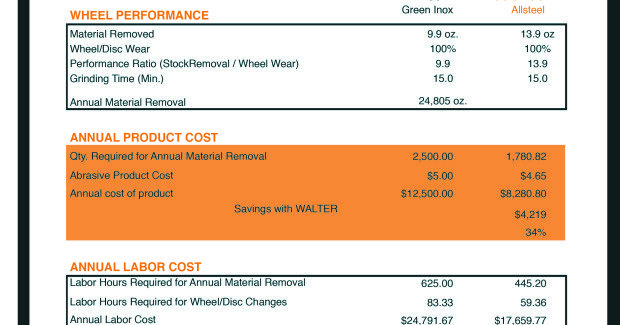

A third example, shown on Figure 3, is Chicago Metal Rolled Products (Chicago, IL), which revealed an overall product and labor savings of 30 percent, or more than $11,000 in annual savings.

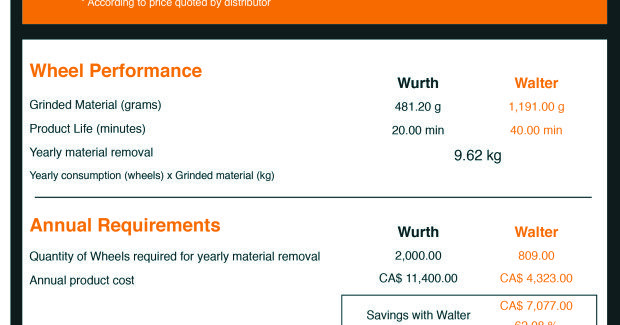

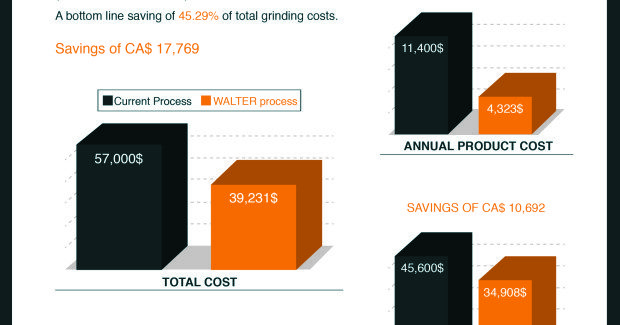

Figure 4 and Figure 5 comes from a Productivity Program Report for LCL-Bridge Products Technology Inc. (Lachine, Québec, Canada), which specializes in the design, manufacture and production of new and retro-fit precision products for bridges, viaducts, stadiums, dams, off-shore platforms and high rise buildings. The analysis revealed more than 45 percent savings in overall grinding costs.

Rather than focusing only on energy savings or reducing costs associated with large equipment, manufacturers looking for potential savings in their plants should take the time to investigate just how much money they could save by switching out an abrasive. In doing so, they should evaluate fully how labor costs tie into the equation.

References:

[1] Modern Distribution Management, How to Get Customers to Fight for You, by Lindsay Konzak, March 10, 2013.