Advanced Seam Finding Helps Blind Welding Robots to See

Servo-Robot showcases their new Advanced Seam Finding Module, a user-friendly software package that provides vision to a blind robot in just a few steps and helps that robot produce only good parts.

Posted: October 4, 2015

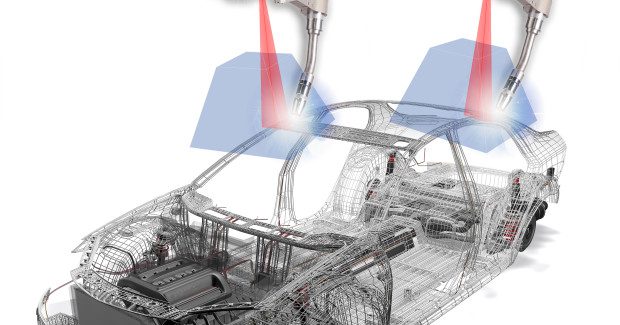

In Booth N-22058, Servo-Robot Inc. (St-Bruno, QC) showcases their new Advanced Seam Finding Module (ASFM), a user-friendly software package that provides vision to a blind robot in just a few steps and helps that robot produce only good parts. ASFM is designed to provide a complete set of functions related to seam finding in order to ensure proper position of the welding torch despite weld joint variation or part position errors. ASFM does not require advanced programming knowledge and can be installed in robots equipped with an Ethernet TCP/IP interface and a laser-vision camera from Servo-Robot, such as i-CUBE. The camera takes measurement data in any orientation and gives an accurate feedback of the correction to apply to the robot trajectory.

Also being introduced on display will be the new i-CUBE/X robotic hybrid laser sensing system that integrates dual-laser range imaging with optional sound recording and ultrasound range detection for high-speed and precision measurement of metallic parts, identification of features and part location. This compact system with rugged design increases robotic process flexibility and reliability, and reduces manufacturing cost. Its dual cross-line laser can measure precise 3D position and orientation in a single snapshot thus drastically decreasing the overall measurement process cycle time. This system also includes long-range ultrasound sensing capabilities to detect object presence, distance and size to provide information and feedback to robotic systems. All these components are integrated into the same compact unit with a TCP/IP interface.

Servo-Robot Inc., 1370 Hocquart, St-Bruno, QC J3V 6E1, Canada, 450-653-7868, Fax: 450-653-7869, [email protected], www.servorobot.com.