The Next Big Thing in Sheet Metal Fabrication

The competitive advantages of laser welding are generating all sorts of excitement as new advancements have minimized the initial investment required and offer a more affordable entry for job shops.

Posted: September 2, 2015

It all began back in 1960 at the Hughes Research Laboratory in California, where Theodore Maiman created the world’s very first working laser by shining a flash lamp on a ruby rod. At the time, this momentous discovery birthed the phrase, “the laser is a solution looking for a problem.” Over the years the potential and purpose for the laser has grown significantly, and the metal cutting industry has enthusiastically embraced the laser as a fast, flexible and efficient solution. Now metalworking shops of all sizes, from the large OEM to the small family-owned job shop, recognize the benefit of the laser not only as a device to cut metal, but also to weld it together.

Perhaps the premiere motivating factor for investing in laser welding equipment comes down to a reduction in the costs of manufacturing a finished part. A laser-processed part is often pristine, which eliminates secondary finishing requirements. Filler material is rarely required, which drastically minimizes or eliminates the need to grind and smooth the finished part. Other advantages include greater accessibility to the weld, joining flexibility, strength, consistency and other factors that confirm why laser welding has grown steadily in the fast-evolving world of sheet metal fabrication, where improvements in cutting and bending have been substantial. An obvious next step is to implement a welding process that will properly and truly complement those technologies.

PART DESIGN

The most common question posed by job shops that are interested in entering the world of laser welding is, “are my parts right for laser welding?” Many fabricators find it surprising that their existing method of manufacturing a product can often be adapted to laser welding with very little additional effort. There are, however, some considerations.

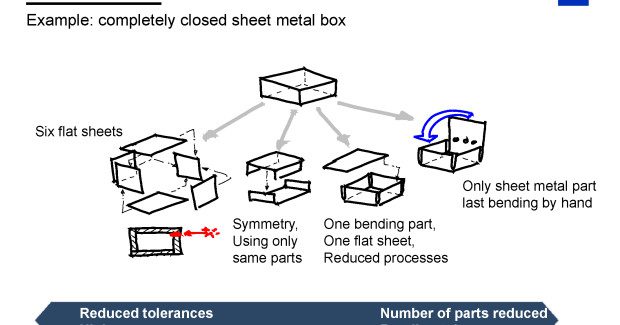

First and perhaps most important: one must pay attention to seam gaps. One of the major benefits of laser welding is the elimination of filler material in the majority of applications. Most seams are joined by fusing the two pieces together, minimizing material costs and eliminating costly and labor-intensive additional downstream processes. As far as part design is concerned, there are different approaches to the development of a product for manufacturing. For example, consider the example of a completely enclosed box. With conventional means, one may choose to bend the base and all four sides from a single piece of sheet metal, welding the flat top piece to the formed bottom to complete the enclosure.

With laser welding, overall tolerance, accuracy and finished part quality can be improved by either forming all sides individually or bending two pieces such that the bends on one part create the sides of the box and the second part creates the ends. These small changes to product design should not be daunting, especially since modern 3D engineering software makes all of this rather easy. Equipment OEMs and other machinery suppliers offer training courses to teach designers how to properly develop products to be suitable for laser welding, which can be highly beneficial and less intimidating in helping a shop make the transition from conventional welding to laser welding.

FIXTURING

Parts designed for laser welding work best when configured for easy integration with shop fixtures. Consider the use of slot and tabs to aid in self-fixturing or as reference points for the fixture. Contours can also be used to help ensure alignment. Fixturing for laser welding primarily involves three different approaches. If volumes are low, such as producing prototype work or creating samples, a simple “tacking” style setup is sufficient. For this, the laser or a conventional weld is used to spot the individual pieces together beforehand.

A second approach is to use the laser itself to create a fixture. An increasing number of shops rely on self-built custom sheet metal fixtures that are designed to their own specifications using their own equipment. Many fabricators find this to be a flexible and cost-efficient way to positively impact throughput, consistency and quality. If sheer volume is the ultimate goal, it might make sense to invest in a “fixturing machine” that features multiple locations for multiple components and automates the alignment and clamping of the product that will be welded. Though this fixturing process can be costly, it is also highly accurate and efficient and enables the processing of the greatest amount of product per hour.

All of these process advantages are driving the excitement that surrounds laser welding. Additionally, new options and technologies are available that make the process less expensive, easier and more reliable. For example, there are optical systems that allow for automatic compensation for any misalignment of the part within the fixture, and also the ability to optimally use one laser source to power up to four individual machines. Advancements such as these minimize the initial investment and offer a more affordable entry into laser welding. Laser welding is the next big thing in sheet metal fabrication, and with the latest developments, it is easier than ever to get started.