Reduce Costs by Blanking In-House

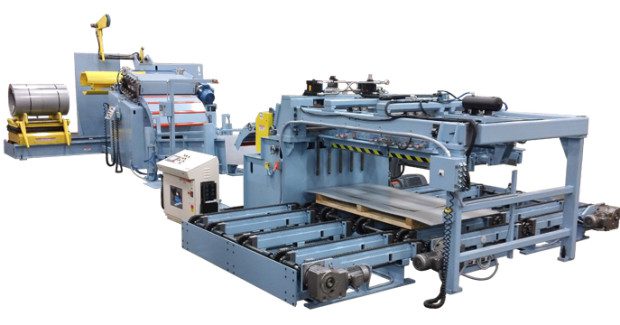

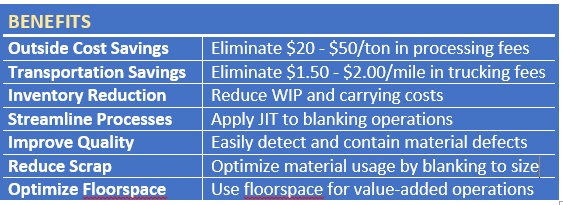

Blanking in-house with a “Value-Added Series” Cut-to-Length (CTL) line from COE Press Equipment provides flexibility to run blanks in the sizes needed as needed, reducing inventory, scrap and overall processing costs while improving quality.

Posted: September 14, 2015

In Booth S-4734, COE Press Equipment (Sterling Heights, MI) will calculate savings – based upon ton-usage and toll rate – that can be achieved by blanking in-house with a “Value-Added Series” Cut-to-Length (CTL) line. In-house CTL lines provide flexibility to run blanks in the sizes needed as needed, reducing inventory, scrap and overall processing costs while improving quality. “Value-Added” Series CTL lines are built using standard COE equipment that is configured to meet each customer’s specific needs. The CTL systems can process coil from 12 in to 84 in wide, .010 in to .375 in material thickness, and 6,000 lb to 60,000 lb coil weights in a variety of materials including cold-rolled steel, hot-rolled steel, galvanized, stainless, pre-painted and aluminum.

COE Press Equipment, 40459 Brentwood, Sterling Heights, MI 48310, 586-979-4400, www.coepress.com.