When Less Is More

The automation behind CAM nesting software helps shops become more competitive by reducing non-cutting time and doing more with less. Here are some of the latest nesting software advances and proven ways to use them to help your shop operate more efficiently and further reduce costs.

Posted: August 4, 2015

Shops use CAM nesting software to address many varied and often unique needs that all share one common theme: doing more with less, all while operating more efficiently and reducing costs. Just like the shops who use it to cut parts, nesting software itself is dynamic and continuously being improved to meet customer and market demands. Here are some of the latest software advances and proven ways to use them to help you get the most out of your automated nesting operation.

REDUCING SCRAP MATERIAL

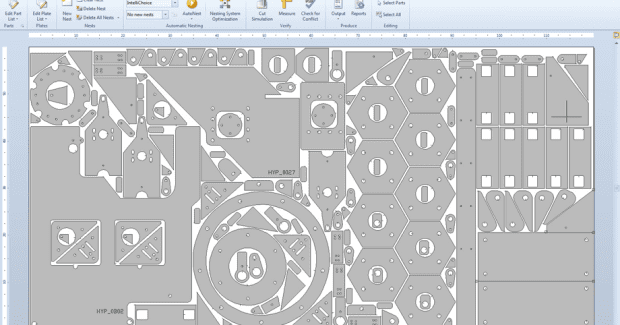

There are several drivers impacting material utilization delivered by today’s nesting software. Some are more top-of-mind than others during the purchase process, but all are worth understanding. One core function of nesting software is to automatically nest parts in the most efficient manner possible, quickly and without manual intervention. More than one factor is involved in this process.

First, the nesting engine within the software typically contains a number of nesting strategies, each of which might be suited to delivering optimized material utilization for a given general style of part geometry, such as rectangles. Since parts that are assigned to a single nest or a job containing more than one nest are rarely the same geometry, and since individual part quantities vary, a single nesting strategy typically won’t deliver optimal results. One successful technique is to use a nesting approach that leverages the optimal strategy for various combinations of parts and quantities to deliver highly efficient nests, continuously seeking the best strategy for the available parts as the nest is built. Nesting operations can be performed rapidly using multi-threading technology that draws on the numerous processors in the personal computer to work on different tasks simultaneously.

https://youtu.be/S4DUxiEYNAg

Another approach used to reduce scrap material is to run nesting trials that calculate every possible combination of parts, full plates, partial plates (remnants), and different nesting strategies to automatically identify the best possible outcome. As the best combination of material and strategy is identified, it is saved to the job and the nesting trials continue, using the remaining parts and material. For example, ProNest software accomplishes this using its Nesting System Optimization module that also caters to cut-to-length coil applications and allows users to prioritize the use of remnants over full sheets and minimize working capital tied up in inventory.

A third method that may assist with material scrap reduction is increasing the volume of parts available for nesting at any one time. Using work order management capabilities within the nesting software, direct connection to an MRP/ERP system allows for direct, real-time import of customer part requirements to the part list where they may be automatically grouped, reducing the need for nesting operators to sort through paper work order “travelers.” Additional benefits of integrated work order management include automatic part tracking with direct feedback of nesting information back into the MRP/ERP system, better on-time delivery by reducing delays created by data entry errors, and by combining orders users reduce time spent setting up individual jobs and achieve longer continuous runs.

Finally, ensuring material separations and lead in / out lengths and styles that are appropriate for the material type and thickness being cut will also help reduce material waste. Factory-tested parameters or built-in process expertise installed within the nesting software are an ideal solution and allow high-efficiency cutting from day one. Other tools include common line cutting, where the straight edges of one or more part are joined together during nesting to eliminate the part-to-part separation. While only applicable in some scenarios, common line cutting can reduce scrap material by several percent if used across the entire nest.

REDUCING REWORK

Machine tool builders continue to push the envelope by incorporating new capabilities into their systems. In response to these machine enhancements, and via integrated hardware and software development, programming software strives to allow users to gain the most from their machine investment. For example, automated bevel-cutting has existed for a number of years. Recent developments with bevel head designs and plasma torch design have played a role in the increased adoption of automated plasma bevel cutting. Challenges with job setup times had persisted, due in-part by programming difficulties and negatively impacted part accuracy. Today, however, factory-tested bevel setups such as True Bevel™ technology that is integrated for use within the nesting software take the guesswork out of the plasma bevel-cutting process when working with mild steel to cut common bevel types such as A, V, and Top Y-cuts. This significantly reduces rework and secondary grinding operations and greatly reduces setup time and scrap material involved in new job setups.

Another area that traditionally impacts shops and is routinely covered during purchase decision-making is the rework and secondary processing related to achieving bolt holes. During recent years, solutions have been developed and released to the market that allow bolt-hole quality to be delivered automatically, without operator intervention at the machine. Software is a key ingredient to this recipe because moving parts to another machine for drilling is no longer required. For example, True Hole Technology® is one such solution and is deployed, in part, via nesting software.

REDUCING NON-CUTTING TIME

Machine tool owners are always interested in seeing the same output – in less time – from their equipment. The right nesting software can impact this in a number of ways. Cutting head collisions with tipped up parts can halt production and cause costly machine damage. While machine operators are careful to keep away from tipped-up parts and other obstacles that might collide with the cutting head, this can mean having the operator watch carefully over the whole process or cutting the entire nest with full head raises. These steps might prevent collisions, but they take a long time to complete due to all the up-down motions. Collision avoidance technology has advanced significantly in recent years to help avoid wasted time and machine damage.

For example, with collision avoidance enabled nesting software can automatically adjusts leads, traverse paths and the cut sequence to avoid possible head crashes and allow for safe head-down motion and faster job completion. This is accomplished in several ways. First, leads are repositioned so that the head is always moving away from the previously cut profile. This means the head is no longer in danger of colliding with previously cut parts or cut-outs that have tipped up. Also, exterior leads are positioned closer to the next part in order to minimize traverse time. Second, the internal cut sequence within a part is optimized to best support collision avoidance and minimal traverse time. Third, rapid traverse paths between cuts are routed around potential tip-ups to further reduce the chance of crashes. Collision avoidance is recommended for use with plasma, laser, and waterjet processes. For example, collision avoidance is a key element of productivity solutions such as Rapid Part™ technology.

If the job can’t be programmed, then the job can’t be cut. There are a few scenarios that can lead to this, but when it happens technical support responsiveness and knowledge are imperative to getting production back in motion. For example, occasionally and without warning a PC crashes, needs replacing and software must be reinstalled. Alternatively, a programmer may be on vacation or away on sick leave, meaning someone else must be trained to use the software – and quickly. In this sort of situation a global team of technical support engineers and channel partners may save the day and help reduce non-cutting time.

Sometimes it’s difficult to grasp how CAM nesting software and the support that stands behind it can have such a large impact on shop efficiency, productivity and competitiveness – but it can and it does.