Little Options, Big Difference

The inherit flexibility of this CAM nesting software allows a job shop to not only program all of the different machine tools on their shop floor, but manually manipulate the options as needed to meet a wide variety of changing demands.

Posted: August 4, 2015

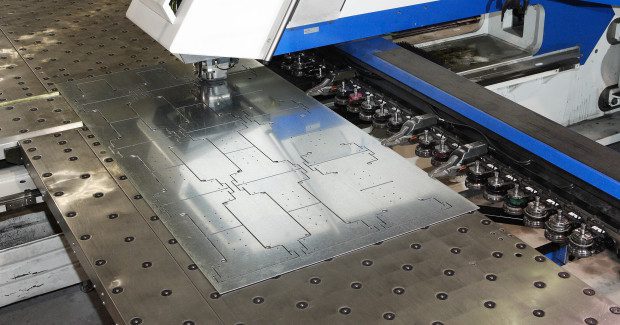

Sometimes even all the know-how in the world won’t help when you don’t have the right tools for the job. If you’ve ever struggled to use a standard screwdriver on a task that calls for a Phillips head, you know firsthand that even the smallest tools can make the biggest difference. Such was the case for Advanced Metal Components, Inc. (Swainsboro, GA). Having made a habit of embracing technologies that help it produce high-quality parts while remaining competitive, the 38-year-old precision sheet metal manufacturer has enjoyed decades of success. The shop found itself in unknown territory, however, when it purchased a new Amada EMK 3610 turret punch fabrication center and simply could not make it work.

After struggling to successfully program the machine, senior product engineer Dawn Phillips, who was tasked with getting the Amada online, knew that it was time to replace the wrong tool with the right one. “We had a new machine tool that wasn’t being used to its full capacity. The programming software we had was not maximizing the full capability of the machine,” says Phillips, an engineer with 31 years in the manufacturing industry, ten of them at Advanced Metal Components. “The software simply wasn’t fulfilling our needs. We struggled for a long time to get it to operate as was expected, but we finally reached the point where we realized we weren’t going to get to where we needed to be.”

Like any shop, Advanced Metal Components simply doesn’t have idle time to spare. Among its repeat clients is a major international producer of industrial equipment, and meeting delivery dates can be challenging. “Our client base is fairly diverse,” notes Phillips. “Though we are considered a job shop, we actually do a lot of repeat work.” When she set out to find software that could program the Amada, she also looked for a CAM solution that could program all of the shop’s machinery, including two TRUMPF laser cutting systems, three TRUMPF punching centers, the Amada 3610, insertion presses, press brakes, and more. “Our goal was to have one programming software that covered everything so that we wouldn’t have to learn to use so many different systems,” explains Phillips.

The company ultimately chose the Radan sheet metal CAM solution by Vero Software (Forest Lake, MN) because Phillips had successfully used it in the past. Her experience was overwhelmingly positive and she found the software’s capabilities and customer support ideal, so the shop acquired the software in September of 2014 and quickly brought it online. Phillips estimates that the entire process, from implementation to full integration, took fewer than three months. Among the software features that Phillips feels set the software apart are its “straightforward interface” and ease of use. “Importing geometry is very easy,” she says. “The interface is clean and there aren’t unnecessary things cluttering your workspace. I think this is really easy to use as far as programming software goes.” She also cites its inherent flexibility as a major benefit and especially appreciates the ability to manually manipulate punching programs.

“Radan will automatically apply the tooling in a relatively desirable way, but every programmer wants to program it a different way,” she explains. “It will get the job done automatically, but there are always little tweaks you can make to improve efficiency at the machine — and this software allows us to do that.” Within that same vein, Phillips also appreciates that it allows the user to customize tooling sequences. As Advanced Metal Components manufactures a high number of extruded holes, customizing sequences in specific instances leads to greater efficiency and standardization. “Once you get your parts nested on a sheet, you can apply order texts for different programming scenarios, and it’s very editable,” she says. “Before this, we had to go in manually and pick all of the tools. Now that is a saved order text file. One may be ‘Extruded Hole Punch,’ while another might be ‘Embosses.’”

Due to its range of demands, the shop performs both static and dynamic nesting, and the software’s nest customization features allow Phillips to designate the amount of time spent creating dynamic nests. “You have the options within the software to tell it not to spend any more than two, four, ten, or however many minutes to maximize a sheet,” she says. “These little options can make a big difference. We’ve found a happy medium and feel like we are producing better nests, and more quality.”

Additional time savers for Advanced Metal Components are the common-line cutting and interlocking capabilities. Common-line cutting is performed when two parts share a common line, and the distance between them is only the width of the tool used to cut. Interlocking parts are creatively nested parts that, for instance, may be ‘L’ shaped and rotated 180 deg for nest maximization. “We all just feel that the software has given us more yields,” notes Phillips. “The software has more than paid for itself in just the time that we have spent on it.”

Advanced Metal Components, Inc., 720 Empire Expressway, Swainsboro, GA 30401, 478-237-8994, www.advancedmetalcomponents.com.

Radan | Vero Software Company, 25 North Lake Street, Suite 220, Forest Lake, MN 55025, 651-982-0100, Fax: 651-982-6055, www.radan.com.