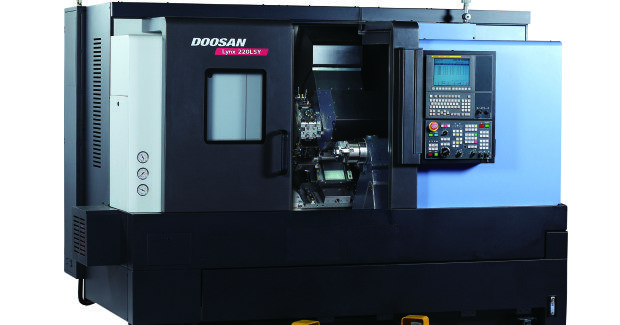

Compact Multi-Tasking Turning Centers with Y-Axis

With its Y-axis, the affordable and high speed Lynx 220LSY Series from Doosan can drill and tap off-center cross holes, mill flats, and rough and finish key-ways.

Posted: August 24, 2015

The Lynx 220LSY Series from Doosan Infracore America Machine Tools (Pine Brook, NJ) is a range of affordable, compact and high-speed Multi-Tasking Turning Centers featuring a Y-axis — a very important feature, as milling and drilling capabilities of the Y-axis do away with the need for secondary machining operations that might otherwise be performed on, say, a milling machine. The result is consistent part quality, predictable throughput and no operator intervention. Non-lifting turret and roller Type LM Guide ways provide high-speed performance and superior accuracy. EZ Guide i conversational programming makes the series quick and easy to set-up.

BASE & GUIDE WAYS

The bed is a single piece Meehanite® casting with a heavy ribbing to prevent deformation and twisting. The guide ways are on a 30 deg angle to maintain a minimal and constant distance from tool tip to guide way, thus ensuring maximum rigidity and virtually no deformation under heavy loads. The slant angle also provides good chip flow as chips and coolant slide downward into the chip pan.

The linear guide ways are roller type for extra load capacity and rigidity. Quality high precision linear motion guide ways are used on all axes to allow high rapid traverse rates. The X-axis rapid traverse rate is 1,181 ipm and the Z-axis rapid traverse rate is 1,417 ipm. The LMG has a four-block of each axis and circular-arc contact design. The guide way rails are heavy-duty with a width of 1.2 in X-axis and 1.4 in Z-axis. The guide ways are widely spaced to ensure stability; they are fully protected by heavy gauge steel covers.

- Swing over bed: 6 in, swing over carriage:15.7 in, maximum turning diameter: 11.8 in, maximum turning length: 20.0 in.

- X-axis travel: 8.07 in, Z-axis travel: 22 in.

Y-AXIS

The Y-axis greatly increases the number of work pieces that can be machined complete without using expensive custom rotary tool holders. The Y-axis enables the milling cutter to machine above or below centerline. A few of the operations possible with Y-axis are drilling and tapping of off-center cross holes, milling of flats, and rough and finishing of key-ways. Y-axis travel, 4.13 in (±2.065 in), rapid traverse, 394 ipm.

SPINDLE, SERVO TURRET, BALL SCREWS AND DRIVES

To maintain perfect alignment and center height regardless of the bed temperature, the robust headstock casting is mounted on the same plane as the tailstock. The headstock is ribbed on the outside of the casting to increase the surface area for heat dissipation. The heavy-duty spindle is supported by a double row of angular ball bearings and cylindrical roller bearings in the front, and double row of cylindrical roller bearings in rear. Cylindrical roller bearings have a large contact surface that provides rigidity for high surface finishes. All spindle bearings are precision class P4 (AFBMA-B7) and are permanently grease-lubricated.

A high torque servo motor rotates the turret at high speeds and is a non-stop bi-directional, with a fast 0.11 second next station index time. Turret indexing is possible during rapid traverse movement away from the work piece. The non-lifting design eliminates the possibility of chips reaching the coupling.

The X-axis ball screw is pretensioned for accurate positioning and thermal stability. The thrust bearings are precision class P4 (AFBMA-B7) angular contact type. Ball screws are centered between the guideways and are directly mounted to the AC servo motors without intermediate gears or belts to minimize backlash. Each axis has an electric torque limiter to protect the ball screw and minimize damage in case of a (heaven forbid!) crash.

Bar capacity: 2 in (Lynx22LYA), 2.628 in (Lynx22LYC). Chuck size: 6.5 in (Lynx22LYA), 8 in (Lynx22LYC). AC motor spindle: 20 hp.

Number of turret stations:12. Number of index positions: 24. Tool holder type: BMT 45. Boring bar diameter: 1.25 in.

SUB SPINDLE

The sub spindle enables the complete machining of parts in one setup. The full C-axis design allows milling, drilling, and tapping on the back sides of parts. The sub spindle body is accurately positioned by a ball screw and servo motor. The spindle is supported by angular contact bearings in the front and cylindrical roller bearings in the rear. The sub spindles can be synchronized with the main spindle at speeds up to 4,500 rpm for “on the fly” part transfer. Parts can be automatically ejected into the standard parts catcher.

EASE OF OPERATION

EZ Guide i is standard on all Lynx Series turning centers and enables users to program and run the machine on the shop floor using a conversational programming system. “Conversational” simply means that the user begins a machine process in a friendly dialog box by pushing a selection button. EZ Guide i requests only needed information pertaining to that process in the form of easy to understand prompts. The interactive process guides the user through each process needed to machine the part.

Further, the operator’s console is mounted on the right side and can swivel for easy viewing. To minimize set-up time, manual controls are provided for turret indexing, spindle and feed functions. All push buttons on the operator’s panel are sealed from coolant or dirt. Knobs for adjusting chuck and tailstock pressure are located on the front of the machine.

Doosan Infracore America Machine Tools, 19 Chapin Road, Pine Brook, NJ 07058, 973-618-2500, www.doosanmachinetoolsusa.com.