CAD/CAM and the Smart Factory

Integrated sheet metal fabrication software is moving far beyond nesting and production functions to step into Industry 4.0 management of end-to-end data flow and business administration tasks.

Posted: August 4, 2015

New levels of automation are making the “Smart Factory” and the concept of Industry 4.0 an increasing reality in some of the latest CAD/CAM software that now functions with data management capabilities and advanced machine automation and intelligence to drive increases in the efficiency, flexibility and profitability of sheet metal fabrication while delivering high quality products. A CAD/CAM programming system, fully integrated to order management systems for end-to-end data flow, can be a first step toward Industry 4.0.

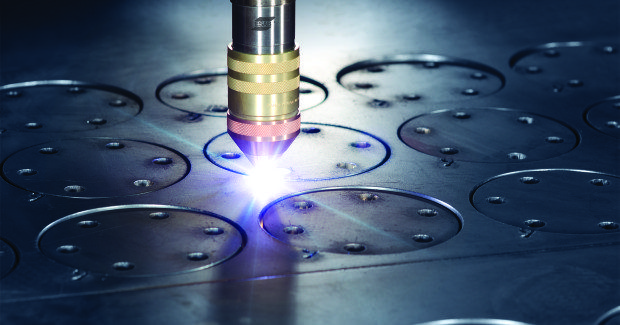

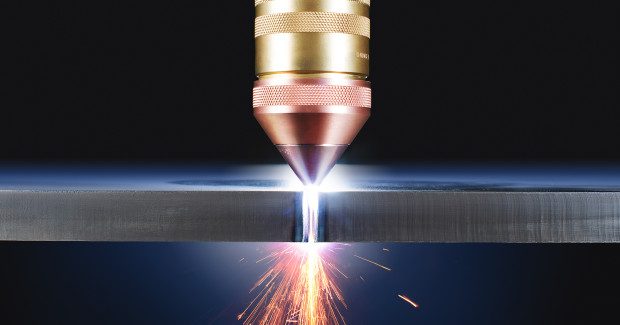

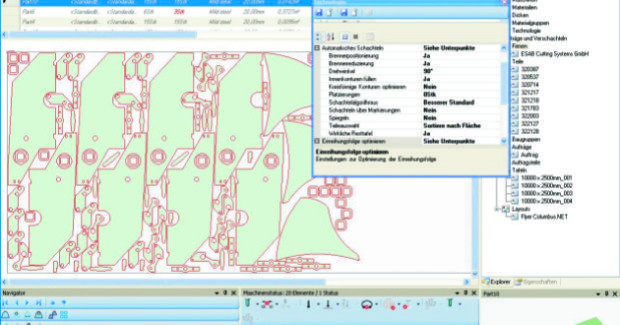

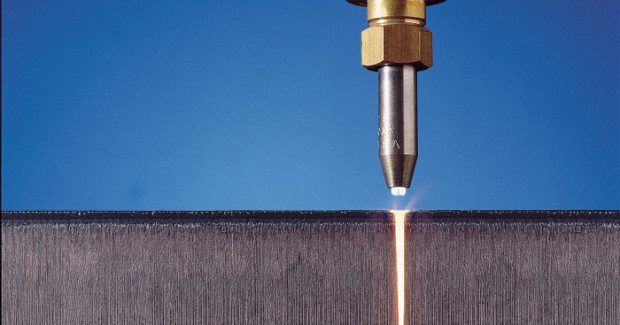

For example, Columbus® software was developed as a CAD/CAM and nesting software to optimize the cutting process for plasma, oxy-fuel, laser or waterjet cutting machines. This is the first software system of its kind to be developed and maintained by a cutting machine manufacturer, so its features are built around generating high cut quality through tight integration with the machine, controller and cutting processes. In comparison, other CAD/CAM software programs are usually machine independent – not closely tied to the NC controller. While Columbus can be used to program different makes of cutting machines, it is especially effective in tapping the full potential of an ESAB cutting system, where the software automatically creates and assigns technologies for parts programmed to use the latest machine features, such as automatic multi-pass beveling, SmartCycle and Precision Hole Technology.

Think about a shop that needs to create bolt-ready holes with plasma requires cylindricity measured in thousandths of an inch. To achieve this, all aspects of the plasma cut must be carefully controlled, including the lead-in and lead-out, height control, speed, acceleration, kerf offset, and plasma gases. An integrated system of software, plasma, CNC and cutting machine fully automates every parameter that impacts hole quality. This degree of Precision Hole Technology makes it almost effortless for any shop to produce high quality cut holes and edge cuts down to a 1:1 diameter-to-thickness ratio on material from 10 ga to 1 in thick.

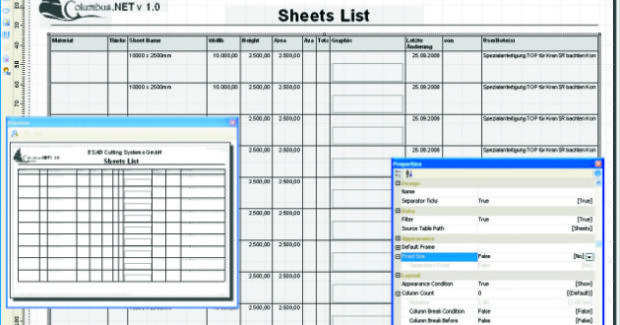

The base module of Columbus software is dedicated to creating the basic machine program from geometrical information. Because the job of programming the CNC cutting equipment is only one part of the equation, the capabilities of this software have evolved based on the many tasks that make up the daily work and work preparation for cutting. These tasks include input of order and ordered parts data; import of the part geometry or preparing the drawing itself in the nesting system; part nesting; calculating work time schedules for the workshop, etc. From the end user’s need to do more than just basic part programming, integrated modules were developed to be combined with the base module to address a shop’s process needs, from part design/programming to part production and beyond to data management. The user can adapt the software package with the various modules that best suit their needs.

In a small fab shop with a single cutting machine, the work prep tasks may be readily accomplished. Medium-sized shops (as well as smaller shops, depending on their reporting requirements) will need the assistance of administrative software systems for the best overlook and planning ability. This need has increased in the last 15 years as fewer workers are available to perform these tasks. Columbus software is able to assist and guide the user through all the administrative work, in addition to ensuring the best quality and productivity from the cutting program.

Getting the data into the workshop is step one, but what happens next? After the parts are cut, how is data transported to the next operation? How is it commissioned? What about post calculation and tracking of orders? Many job shops are required to deliver data with their parts, so full material traceability is often a necessity. The need to collect and transport this data automatically, with minimal manual operation or involvement, is why the DataLeap system was developed to work in hand with the Columbus software.

DataLeap software is, like Columbus, a modular package that is adaptable to the needs of the end user to collect data, monitor machines and analyze productivity and quality. This is accomplished with almost no manual effort, creating a more automated manufacturing process by connecting directly to the CNC control using real time plc data to calculate production results. Using DataLeap, delivery date, material required, and nesting priority of a part can all be specified to let the shop automatically track the part/order through the entire process and track what plate was used to cut the part. As a result, the nesting system is now a tool for production control.

Using these software packages automatically optimizes a shop’s cutting process from the part program through business administration tasks. Order data is automatically imported into the nesting system as soon the orders are released for production by an ERP system. This minimizes lead time by eliminating manual data input, which could shave hours off production time, and also eliminates errors caused by manual input.

Material data is automatically imported as soon as the stock system or material input generates the data that needs to be available for cutting. This results in faster lead time and eliminates the possibility of manual error. The nesting system keeps track of parts and material used on a 1:1 base and saves time by automating the reporting process.

All data that is generated in Columbus can be exported back into an ERP system to monitor the production planning. In producing the part nest, the software calculates cutting times, material requirements, scrap and overhead costs. Reports can be quickly and automatically generated from this high quality data. All data generated is exported into the DataLeap system as the main data warehouse. The programs and working papers are generated semi-automatically and delivered to the work floor. The machine controllers are connected to the DataLeap database to automatically send all the data generated during cutting. All data is linked in the data warehouse by the server system to provide 100 percent traceability for the production process. A webserver-based service grants access to all the data, giving the user the ability to monitor up to the second, to constantly improve and post calculate the production process using extensive reporting capabilities.

Columbus and DataLeap software is ideal for mid- or large-sized job shops and fabricators with more than one cutting machine. These software packages usually don’t make sense for small shops or production facilities with a single, small cutting machine, because those operations do not typically have the need to invest in software with advanced reporting or data analysis capabilities.

Commitment to implementing a data monitored process is essential to the success of data management software. This is usually one of the largest “ouches” a shop will encounter. There must be an all-or-nothing approach, otherwise the data quality suffers and manual bottle necks are created that do not allow for full system success. Users can expect to see positive results after approximately six months. At the 12-month to 24-month time frame, a total return of the investment can be realized, depending on the complexity of the project. Other software systems provide either administration capabilities (nesting) or production functions (MES systems). Columbus, in conjunction with DataLeap, provide the full gamut of capabilities from administration to production to maximize a shop’s productivity.