Welcome to the Internet of Things

On this playing field, anything that can be connected, will be connected. Those who can adapt to connecting will thrive. Those who can’t, well . . .

Posted: July 31, 2015

We have now entered a world where it seems that any and every device with an on-and-off switch now connects to the Internet. In your personal life this includes cell phones, tablets, computers, automobiles, televisions, coffee makers, washing machines, lamps, clothing and wearable devices, your pet’s collar . . . just about anything that comes to mind. In manufacturing the scale grows to include all of these things plus the machinery and production accessories, maintenance equipment, HVAC and security on the shop floor, in the offices, in the yard, at the gate, even the factories themselves are connected at large. That’s a whole lot of connections. In fact, the analyst firm Gartner, Inc. (Stamford, CT) estimates that in five years there will be over 26 billion connected devices. And each of these on-and-off devices that connects to the Internet eventually, through one means or another, will connect to each other.

We are all becoming part of a colossal, unprecedented network of connections – people to people, people to things, things to things – a world that is becoming known as the Internet of Things (IoT). At its core, IoT is really a simple function of collecting data, then analyzing and using it to drive software and hardware applications. But what blows your mind is the sheer scale of integration between all of those hardware and software applications – and trying to grasp the impact all of this will have on manufacturing efficiency and competitiveness is staggering. We don’t have to wait and find out, because even though IoT is still in its infancy, it is already starting to change the way manufacturers view and invest in their technology infrastructure. This is a new and very different conversation about automation.

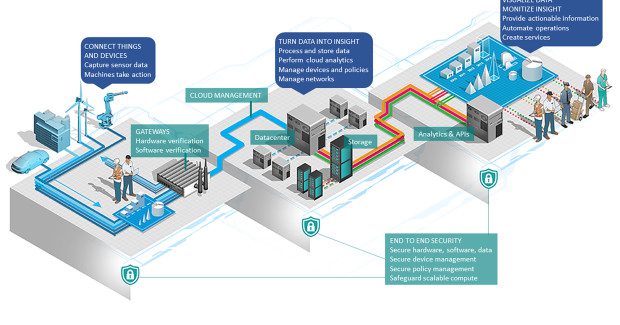

“Smart, connected devices require manufacturers to build an entirely new technology infrastructure that consists of a series of layers known as a ‘technology stack,’” explains Michael E. Porter of the Harvard Business Review. “This stack includes modified hardware, software applications, and an operating system embedded into the device itself. Other layers include network communications to support connectivity, a device cloud containing the device-driven database, a platform for building software applications, a rules engine and analytics platform, and smart device applications that are not embedded in the device. Cutting across all of these layers is an identity and security structure, a gateway for accessing internal data, and tools that connect the data from smart, connected devices to other business systems.”

This is one reason more manufacturers, particularly smaller job shops, aren’t already tapping into IoT. “At this moment in time, to gain any value from the technology requires resources that no one can provide but the largest of enterprises,” notes Will Hayles, a technical writer for Outscale Iaas (Saint Cloud, France), a cloud hosting provider in the U.S. and Europe. In other words, it’s still early. But Porter emphasizes that a great deal of value can be gained from IoT already if manufacturers can use some of their currently connected devices as tools for control, optimization, monitoring, and autonomy. He believes that, as manufacturers collect more real-time data and transmit it wirelessly to Web applications and servers connected to the Internet, three things will happen: (1) shops will gain more precise and accurate monitoring and control of their physical systems, (2) they will increase their business bargaining power as both a supplier and a buyer, which means (3) their own manufacturing competitiveness will reach an all-time high.

But here’s the catch: the huge increase of connected devices used in IoT will, in turn, generate an exponential increase in the amount of data that a job shop or contract manufacturer is required to manage – and managing this intersection of IoT with Big Data is the key to unlocking future manufacturing profitability.

BIG DATA ADOPTION

“We’re all going to have data spewing at us from every direction – from appliances, from machinery, from train tracks, from shipping containers, from power stations,” warns Howard Baldwin, writing for Forbes. “If that doesn’t get you thinking about how to handle real-time data feeds, then nothing will. But here’s a suggestion: Start Now.”

Because IoT is still in its infancy, it hasn’t started to produce an overwhelming deluge of information yet . . . but it’s coming. Big Data, however, has been around long enough now that manufacturers are starting to recognize how its capacity is a prerequisite for tapping into IoT. “Without the proper data-gathering in place, it will be impossible for job shops and contract manufacturers to sort through all of the information flowing in from embedded sensors,” states Hayles. “In other words, without Big Data, IoT will offer a job shop little more than noise. This is why analytics tools are gradually becoming accessible to small and midsized shops to handle large, fast-changing volumes of information,” says Hayles, “while data science has become a legitimate and valued field of study. In short, for most manufacturers, the timing has never been better to look into the adoption of a Big Data strategy.”

At the recent [MC]2 Conference held in Chicago, Bryce Barnes, the senior manager of machine and robot segment at Cisco Systems, Inc. (San Jose, CA), told Tim Shinbara, the vice president of manufacturing technology for AMT (McLean, VA), that “the next Industrial Revolution will be data-driven. Those manufacturers that embrace data will prosper, and those who don’t will be left behind.” In order to create a manufacturing process that you can extract data from, Barnes believes it must be physically open, extensible and secure. “The first question to answer is do you use a proprietary or open standard of communication,” he says. “Next, make sure it is repeatable and scalable. Once you have both of those building blocks, you may then think of ways to secure the environment and build a strategy that produces value.”

What about using data as part of the design process? “Historically, manufacturing systems have been designed with process and control in mind, leaving communications and data as almost an afterthought,” said Barnes. “But what we really have in mind now is to bring data, communications, process, and control all together in one design process. The most challenging part of this is not to decide how to accomplish this, but who should accomplish it. Whether it’s a data scientist or a team of people with many skills, determining the right way to implement your data strategy requires forethought and potentially new hires.”

Welcome to the Internet of Things, where job shops, contract manufacturers and metal service centers compete to make more money by being better at connecting data silos, processing data, communicating it and integrating everything together, all at once, into the faster delivery of better products.