Ignored No More

Here are the reasons why wet dust collectors are a safe and economical solution for manufacturing operations to use in preventing industrial dust explosions.

Posted: July 31, 2015

Industrial dust explosions, previously ignored for so long, have become a very serious problem for industry. The prevention of industrial dust explosions suddenly became a widely discussed issue following the June 5, 2008 televised CBS 60 Minutes report by Scott Pelley in which he asked, “Is enough done to stop explosive dust?” In an article in the New York Times on August 22, 2014, titled The Danger of Combustible Dust, the chairman of the United States Chemical Safety Board (CSB), Rafael Moure-Araso, stated, “From 2008 to 2012, our board documented 50 combustible dust accidents that led to 29 fatalities and 161 injuries.” This documentation was published in the aftermath of a horrific metal dust explosion that occurred in Jiangsu Province, China, that killed 75 people and injured another 185. It also followed on an earlier 2006 CSB report that cited “281 combustible dust incidents between 1980 and 2005 that killed 119 workers, injured 718, and extensively damaged industrial facilities.”

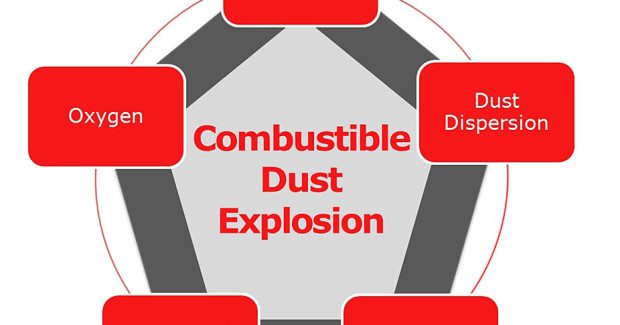

These sorts of dust explosions occurred in practically every state, in many different industries involving a variety of different materials, resulting in enormous economic losses. What actually causes a dust explosion? A dust explosion can only occur when the following five factors are present:

- Fuel, in the form of dust particles.

- Dispersion of the fuel in the form of a dust cloud (frequently produced when a dry filter is pulsed clean).

- Oxygen in the form of air.

- Confinement of the dust cloud in the form of a container (e.g. a dust collector).

- A source of ignition.

https://youtu.be/ZcrjrexvIeE

These five factors form “the explosion pentagon” (as adapted from OSHA SHIB 07-31-2005; updated 11-12-2014). By controlling or eliminating just one of these key factors, the risk of a dust explosion decreases dramatically. Following years of relative inaction, this dangerous problem is finally being addressed seriously through updated codes and standards, legislation, regulation, and enforcement. There is no longer an excuse for any manufacturing operation to ignore or fail to deal effectively with the risks of dust explosions. The cost of preventing industrial dust explosions is necessary, but expensive. Wet dust collectors eliminate three of the five factors that cause dust explosions and reduce this expense significantly in comparison with dry dust collectors. How? The answer can be found in a basic design comparison between dry dust collectors and wet dust collectors.

DRY DUST COLLECTORS

A dry dust collector is the perfect incubator for a dust explosion because the technology uses fabric media to separate the dust from the air. As air passes through the media, dust particles become embedded and remain lodged deep inside the media and on its surface. Periodically, the flow of air through the media is reversed by a pulse of air that blows the dust off the media, forming a dust-cloud that eventually falls to a collection hopper. This is the critical moment when four of the factors required for a dust explosion are present. One spark or hot particle and an explosion can arise.

A range of solutions have been developed to “mitigate” the effects of dust explosions in dry dust collectors that include one or a combination of the following costly equipment:

- Explosion vents which relieve the explosive pressure and direct the ensuing fireball. Dust collectors with explosion vents cannot be installed indoors unless the explosion is vented outdoors. The air can only be recirculated if abort dampers or isolation systems are provided on the dust collector return duct.

- Multiple chemical isolation systems installed on the dust collector and all connecting air ducts. When activated these eliminate the oxygen ahead of the developing flame front and quench the fireball. Dust collectors with chemical isolation systems can be installed indoors.

- Flameless vents which absorb the energy of the vented fireball. Dust collectors with flameless vents can be installed indoors.

- Depending on the particular application, spark detection and spark extinguishing systems may also be required.

None of these systems actually prevent an explosion from occurring. Instead, they direct, suppress or quench the energy after it has been initiated. Each of these interventions requires that the dust collector be of high pressure construction to structurally resist the high internal pressures generated by the various solutions. Consider also that, in addition to the equipment expense associated with explosion prevention systems, these also require expensive maintenance – and many of these solutions do not even guarantee that the dust collector will be useable afterwards.

WET DUST COLLECTORS

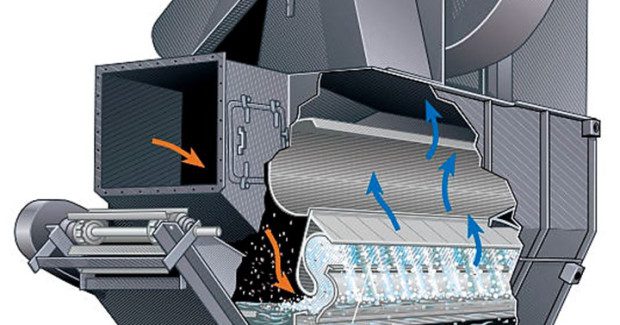

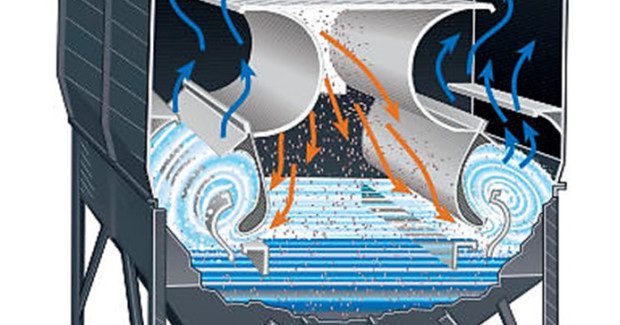

Wet dust collectors use water as a medium for filtering dust from ducted air and typically operate in one of three configurations:

- Hydrostatic Precipitator

- Wet Centrifugal Collector

- Venturi-Type Dust Collector

The very principle by which a wet dust collector separates dust from an airstream eliminates a number of the factors that cause dust explosions. As air containing dust enters into a wet collector and passes through a combination of induced aerodynamic and hydrostatic forces, the dust in the air is “wetted” and transferred from the air to the water. In the case of an explosive dust, this achieves three critical objectives:

- The transfer of the dust from the air removes it from an oxygen-rich environment. Without oxygen, combustion cannot occur.

- The use of water eliminates any potential source of combustion which, in turn, also eliminates the need for spark detection and extinguishing systems.

- Since the dust has been eliminated from the air and is now in a “wetted” state, there is no mechanism by which a dispersed dust cloud can form.

Wet collectors are the recommended technology for the collection of dust generated by the fabrication of lightweight metals such as aluminum, titanium and magnesium. Other industries in which explosive dusts are an issue where wet collection is recommended include those that process food, rubber, plastics, pharmaceuticals, and coal, all of which generate combustible forms of dust. In all of these manufacturing operations, the return on investment is generated by savings in:

- No abort dampers

- No chemical isolation systems

- No flameless vents

- No spark detection systems

- No spark extinguishing systems

- No high pressure construction

- No associated maintenance

STANDARDS

NFPA® 484, Standard for Combustible Metals, 2015 Edition, is a detailed document which in its 19 chapters and ten annexes establish rules and provide guidance with the objective of minimizing “the occurrence of, and resulting damage from, fire or explosion in areas where combustible metals or metal dusts are produced, processed, finished, handled, stored, and used” (NFPA 484-15, paragraph 1.2). All who are involved in any way in the “production, processing, finishing, handling, recycling, storage, and use of all metals and alloys that are in a form that is capable of combustion or explosion” (NFPA 484-15, paragraph 1.1) should be fully conversant with the provisions of NFPA 484 and shall comply in full with all of its various requirements. In general, those would include, without limitation:

- Chapter 9 Dust Collection: (a) Section 9.3.1 Collectors, (b) Section 9.4.12 Wet-Type Dust Collectors, (c) Section 9.4.13 Dry-Type Dust Collectors

- Annex A Explanatory Material, beginning at A.9.3.1

In addition to NFPA 484-15, the basic standard for dealing with explosive dust applications is NFPA 69: Standard on Explosion Prevention Systems, which applies to the design, installation, operation, maintenance, and testing of systems for the prevention of explosions by means of various methods. Once again, all who are involved with the applications discussed here shall be fully conversant with the provisions of NFPA 69 and shall comply in full with all of its requirements. The user shall ensure that they are working with the most current edition of the NFPA standards as well as all governing local authority. For more information on NFPA standards, go to http://www.nfpa.org/.

Please note that the information herein is non-exhaustive and users are responsible for becoming familiar with all applicable laws, regulations, rules, and standards.