Vertical Machining Centers

Take a look at the advantages of affordable flexibility now being offered in the newest vertical machining centers.

Posted: June 4, 2015

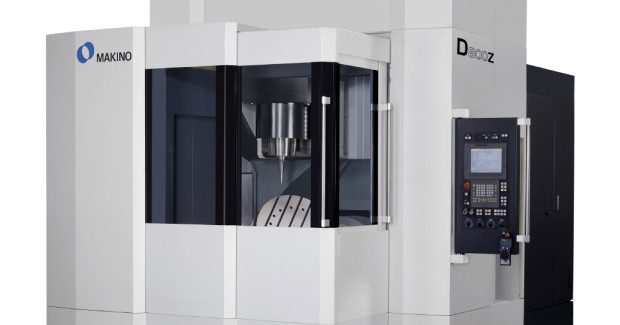

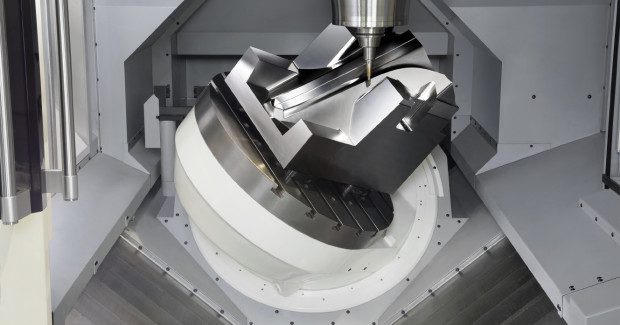

The uniquely designed “Z” shape of the tilt-trunnion table ensures that the center of gravity of the table and work are always captured within the center of rotation of the B- and C-axes. Large-diameter bearings minimize table deflection and provide outstanding stiffness and rigidity, regardless of the angular and rotary position of the work. The direct-drive motor design provides the speed for productivity and precision for tight-tolerance work. The D800Z can be configured with two different spindle combinations: D800Z (#40) and D800Z (#50). The D800Z (#40) offers a standard Cat #40 (or optional HSK-A63) 14,000 rpm spindle. As an option, the D800Z (#40) can also be configured with a 20,000 rpm HSK-A63 spindle. The D800Z (#40) incorporates a 40-tool magazine. The D800Z (#50) offers a standard Cat #50 (or optional HSK-A100) 12,000 rpm spindle. As an option, the D800Z (#50) can also be configured with an 18,000 rpm HSK-A100 spindle. The D800Z (#50) incorporates a 48-tool magazine. The range of spindle offerings provides the ability to customize the machine to suit a wide variety of machining applications. Feed rates of 36,000 mm/min. on the X-, Y- and Z-axes, and 18,000 deg/min (50 rpm) on the B- and X-axes ensure productivity.

The proprietary, next-generation super-geometric intelligence (SGI.4) software developed specifically for high feed rate, tight-tolerance machining of complex 3D, contoured shapes involving continuous tiny blocks of NC data, which ensures production rates faster than standard CNC systems, while maintaining high accuracy. SGI.4 helps provide the lowest cycle times and costs achievable, by reducing machining cycle times on dies, complex cavities and cores, and aerospace parts by as much as 40 percent, when compared to most other control technologies. The D800Z is equipped with a number of 5-axis features, including Tool Center Point (TCP) control, which permits programming based on the tool tip, so that tool compensation features can be applied. Further TCP developments improve the cutter path to achieve greater surface quality. Dedicated user-friendly screens are developed to simplify the overall application of 5-axis machining. Easy-to-apply functions are included to prevent interference between the spindle and trunnion during automatic operation, eliminating collisions.

The D800Z has a two-sided front-door design, for easy access to the spindle and table for setup purposes, and a large window, for enhanced visibility. The machine’s compact size of 3,200 mm x 5,070 mm x 3,600 mm requires less floor space, and its intelligent design facilitates maintenance activities. The D800Z has also been designed to lower a shop’s operating costs through reduced energy consumption. To save energy costs, the D800Z features an eco mode that turns off peripheral devices when they are not needed. The energy-saving coolant system comes with an inverter-driven coolant pump that supplies precisely the required flow rate and timing for each function. The hydraulic unit, with its accumulator, ensures zero power consumption when the pump is idle.

Makino, Inc., 7680 Innovation Way, Mason, OH 45040, 513-573-7200, Fax: 513-573-7360, www.makino.com.

MEET CHALLENGING OEMS AND JOB SHOP DEMANDS

Methods Machine Tools, Inc. (Sudbury, MA) introduces the all-new Methods-Yasda PX30i, a 5-axis high precision, automated vertical machining center featuring exceptional quality, flexibility and economy to meet challenging OEM and job shop requirements. The PX30i features a newly designed direct-drive spindle with self-adjusting preload that is based on proven, renowned spindle technology to improve performance and increase spindle life. The spindle features the torque, speed and horse power to facilitate the efficient machining of a wide range of materials from aluminum to high temperature alloys, including Inconel, titanium and steels with high HRC ratings.

https://youtu.be/j6DwBzgKmIY

At the core of the PX30i is a robust 2-axis rotary table, offering flexibility and speed with a wide range of movement. Providing high efficiency and accuracy to operators with a wide range of performance requirements, the B and C-axes feature a direct-drive motor with advanced thermal stability. Robust bridge and bed designs have been built upon Yasda designs that have long been the choice for the superior metal removal capabilities and high rigidity required for precision machining. The machine table and work envelope are sized for ease-of-operation.

The PX30i offers a turnkey automated machining center solution designed to answer a wide range of manufacturing requirements for OEMs and job shops such as a high volume, low mix of parts or a low volume, high mix of parts with differing lot sizes, part geometries and materials. Offering manufacturers the ability to do lights-out or unattended manufacturing, the PX30i features a full complement of 32 pallet positions storage plus one in the work zone for a total of 33. The Automatic Tool Changer (ATC) and Automatic Pallet changer (APC) features a Methods-developed software program for efficient tool/pallet management and advanced scheduling functions. The ATC can be retrofitted for additional tool capacities of up to 500. To maximize valuable floor space, the PX30i offers a footprint of 25 ft (length) by 11 ft (width).

For more automation capabilities, Methods offers a robot-tended VMC cell that changes multiple workpieces simultaneously. The Twin RoboDrill JobShop Cell features two FANUC D21 RoboDrill vertical machining centers serviced by a single articulating FANUC LR Mate 200iD robot. Multiple parts can be loaded and unloaded simultaneously, rather than one at a time, for faster cycle times. The cell is well-suited for a low-mix, medium to high volume of parts. The FANUC robot enters from the side of each machine, giving operators full access to the front of the VMCs for tool changes, offsets and maintenance. The cell combines FANUC Robotics’ IR Vision System with a flex vibratory infeed system to bring parts into the call. The flex feeder conveys a group of parts into the vision camera’s field of view for inspection, selecting the “good” parts for the robot to load into the machine.

The VMCs are equipped with FANUC 31iB5 controls with FSSB high-speed processing. According to Methods, the control offers streamlined electronics to reduce the number of components. Troubleshooting and maintenance capabilities reduce downtime by enabling users to analyze systems on the RoboDrill VMCs and receive notifications if any of the drives or electronics requires adjustment.

Methods Machine Tools, Inc., 65 Union Avenue, Sudbury, MA 01776, 978-443-5388, Fax: 978-440-9405, [email protected], www.methodsmachine.com.

ATTRACTIVELY PRICED MACHINING FLEXIBILITY

The DMU 65 monoBLOCK® from DMG Mori Seiki USA Inc. (Hoffman Estates, IL) offers high-tech at an attractive price while setting a new benchmark in its class with its convincing performance and highest accuracy features. A wide range of flexibility encompasses this 5-axis machine with its dynamic NC swivel rotary table. The DMU 65 monoBLOCK masters all disciplines in milling technology, from roughing through to finishing, at an uncompromisingly high level and at a very attractive price. In conjunction with the high-speed rotary axes of the NC swivel rotary table, the 1.77 in wide roller guides maximize process stability. The machine uses three-point support for shortest possible start-up times. With its 80.73 sq ft footprint, this is the most compact machine of its class.

https://youtu.be/nQnSRTvL5G4

Despite the small space requirement, the DMU 65 monoBLOCK has an extremely spacious machining compartment. With axis paths of 28.94 in x 25.59 in x 22.05 in X, Y and Z, the entire NC swivel rotary table surface can be traversed allowing the workpieces to be machined in one pass. Certainly a decisive attribute for maximum precision and surface quality. Even oversize workpieces of up to 33.07 in diameter and a weight of up to 2,205 lb can be loaded on the NC swivel rotary table. The operator has unrestricted access to the ergonomic 31.5 in table height in the machining compartment through a 51.56 in wide door opening. Given the heavy weight of the parts, optimum access for loading by crane from above is also possible.

Simple and comfortable operation and loading of the 30, 60, 90, 120 or 180 position tool magazine has not been forgotten. Since the loading station is located in the front area of the machine, the operator can always work in his normal work environment. During make-ready, the control panel can be swung directly towards the tool loading station. The fast sword-type tool changer reduces the chip-to-chip time to a convincing 4.9 seconds. The steep slants of the machining compartment allow swarf to drop unrestricted and the stainless steel lining of the machining compartment ensures long operating life. A wide centrally arranged chip conveyor permits fast and process reliable chip removal towards the rear of the machine.

The DMU 65 monoBLOCK offers modular configurations for the extensive motor spindle system, starting with a standard spindle speed of 10,000 rpm (at torque of 82 Nm), with options of 14,000 rpm (130 Nm), 18,000 rpm (130 Nm) and 24,000 rpm (100 Nm), as well as a sturdy spindle with 10,000 rpm and a 200 Nm torque. The available table variations match the individual application focus. In addition to the standard NC swivel rotary table for workpieces of up to 1,323 lb, there are swivel rotary tables with tandem drives in A-axis for workpieces of up to 2,205 lb or with Direct Drives in A and C axes for highest dynamics and accuracy, as well as the 3-axis version for workpieces of up to 6,613 lb.

An internal coolant supply of up to 1,160 psi and a space-saving chip conveyor towards the rear of the machine allow space-optimized placement of the machine on the shop floor. The machine is equipped with CELOS® software on a 21.5 in ERGOline® Control that runs Operate 4.5 on a Siemens 840D solutionline or Heidenhain TNC 640.

DMG Mori Seiki USA Inc., 2400 Huntington Boulevard, Hoffman Estates, IL 60192, 847-593-5400, Fax: 847-593-5433, www.dmgmori.com.

TURNING ADDED TO 5-AXIS MACHINING

Mazak Corporation (Florence, KY) has introduced turning capabilities into multiple-surface, simultaneous 5-axis machining with the Variaxis i-700T, allows manufacturers from a wide variety of industries, including aerospace, energy and transportation, to bring even higher levels of productivity into their part processing operations. An 18,000 rpm, 40 hp, 40-taper spindle on the Variaxis i-700T features a compact nose design for better part access during side machining operations, where pallet interference might otherwise be a problem. A 30-tool automatic tool changer adds part processing flexibility and contributes to continuous non-interrupted machining operations. With a spacious Y-axis travel of 43.30 in and X-axis of 23.62 in, the Variaxis i-700T easily accommodates workpieces measuring up to 28.74 in diameter and 19.69 in high. Its roller gear cam-driven rotary/tilt table, with 360 deg of rotation in the C-axis and +30 deg through -120 deg of tilt in the A-axis, is supported at both ends and provides stable high-accuracy 5-axis machining.

A direct-drive motor powers the rotary table for both C-axis positioning and turning operations with a maximum spindle speed of 1,100 rpm. The machine performs turning when the A-axis is in the 0 or 90 deg position. The A-axis rigidly clamps to a coupling in either of these positions, allowing for high-accuracy machining over extended periods of operation. With fast 2,362 and 2,205 rapid traverse speeds in the X, Y and Z axes, respectively, as well as the unmatched durability, reliability and speed of its MX Hybrid Roller Guide System, the Variaxis i-700T achieves an overall increase in accuracy, productivity and profitability. The MX Hybrid Roller Guide System increases vibration dampening, extends tool life, handles higher load capacities and eliminates tramp oil in the coolant by utilizing a greener grease-based lubrication system.

The Variaxis i-700T sports the new MAZATROL SmoothX CNC that is a key element – along with new machine hardware and servo systems – of Smooth Technology. As a dramatic evolution in the advancement of machine tools, Smooth Technology is a complete process-performance platform that spans the entire part-production landscape from programming and setup to metal removal operations and automation to monitoring and data collection/transfer. When paired with an optional two-pallet changer, the Variaxis i-700T makes it easy to achieve continuous part processing. This simple and efficient automation feature enhances productivity by allowing operators to load, unload and inspect a part on one pallet, while the machine continues to work on a part fixtured on the other pallet.

Mazak Corporation, 8025 Production Drive, PO Box 970, Florence, KY 41042, 859-342-1700, Fax: 859-342-1865, www.mazakusa.com.