Getting Better All the Time

The eye-opening story of how one vertical machining center renovated a small machine shop that makes prototypes and runs small batches for electronics, aerospace, glass and industrial printing applications.

Posted: June 4, 2015

Small-business owners like Tony Chastenay at All Axis Research & Development LLC (Claremont, NH) know that acquiring new orders is crucial to growing his company and helping build a better life for his employees who devote so much energy and passion to work on a daily basis. “I know it’s hard to have a stable career in this day and age,” he said. “I also realize there are risks in working for a small business, so I make sure that taking any risk is worthwhile. Our employees must have a workplace where they feel secure, and our customers must feel confident they get quality products delivered on time. That is what matters most.”

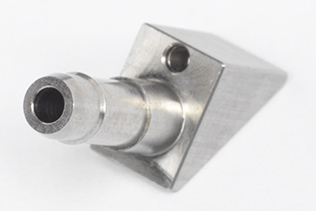

Technology is the competitive weapon to achieving this goal, and All Axis uses it to efficiently create prototype parts for clients in the electronics, aerospace, glass and industrial printing industries. “Making prototypes is not a cookie-cutter process. Each job has its own challenges,” noted Chastenay. “To handle this kind of work, you can’t just have talent. You need modern equipment, too. We want to be the best, so we try to buy the best.” To handle the sheer diversity of materials and part variety, the shop installed a PS95 vertical machining center from Makino Inc. (Mason, OH) that reduced its cycle times by up to 50 percent – showing its commitment to completing jobs on time, on budget and with exacting tolerances.

Ever since a high school trade class piqued his interest, Chastenay enjoyed machining and working jobs where he used his hands, tinkering with cars, trucks and heavy equipment. After high school he worked at an aerospace manufacturer that handled many exotic metals. When a friend recommended an open development position at another company, Chastenay eagerly started work as an experimental machinist, then graduated to supervisor and later into management. “I stayed for 14 years and learned a lot about engineering and design,” he recalls. “I enjoyed handling the more challenging projects and overseeing the experimentation, test machining, data collection and feedback.”

When the experimental machine shop was discontinued, Chastenay saw an opportunity to go into business for himself producing prototypes with a Bridgeport mill he used at home to perform side jobs. All Axis was born with blessing and encouragement from his former employer, who even qualified his business as a vendor before he even left the company. “I had a great transition to business owner,” he smiles. “I still work with them on new designs.”

At All Axis, he handles engineering, creates and proves out prototypes and makes fixtures for them, and often runs small-batch jobs under ten parts for clients. As the work evolved, his shop learned more about their equipment capabilities through many setups and programming. “We found that we needed more capacity and better performance,” stated Chastenay. “Our schedules were already stretched thin. In fact, three of our commodity vertical machining centers were already scheduled out for the entire year.” Running equipment nonstop left the shop no room for downtime. With no backup for an idle machine, a customer could be lost or a loss in profit could be more than the machine itself. Moreover, the shop was already experiencing equipment reliability issues.

“We decided to invest in infrastructure,” said Chastenay. “We needed to rough cut tough materials on something extremely rigid with fast spindle speeds that would work well for a lot longer than other machines and still retain its value.” All Axis had never dealt with distributor Able Machine Tool Sales, Inc. (Agawam, MA) but received good recommendations about them from other shops. After seeing the PS95 in action Chastenay purchased one in December 2013. “We have now transitioned much of our heavy hogging and hard material applications to the PS95. We machine a lot of 45 HRc parts and produce some that are 41/40 heat-treated and find that we can get the highest metal-removal rates on this VMC compared to our other machines.”

All Axis appreciates the standard through-spindle coolant and the chip conveyor that it didn’t have before. “Not having to remove chips from the machine is very efficient,” explained Chastenay. “We used to shovel enough to fill a 55 gal drum on each part. Now, instead of shoveling chips we make them. The through-spindle coolant speeds up cycle times on milling, drilling and plunging. We can now complete pecking operations in one clean Z-axis plunge.”

The PS95 is the fastest machine in the shop. Machine utilization is up and All Axis is more competitive. One part comprised of A2 tool steel was transferred from a previous machine over to the PS95. Cycle time was cut in half, from 40 minutes per part to 20 minutes. Other parts transferred to this VMC have seen 20 percent cycle-time reductions without adjusting processes. The shop also saves time by using progressive fixturing to consolidating setups. The PS95 follows the programmed geometry with less tool deflection and better blends, and its larger work envelope and travel takes on larger part applications and performs multiple operations in a single load for faster completion of parts.

The shop achieves one full decimal point higher resolution and adjustability with the PS95 controls and is able to use more advanced tooling. “We can drill through six inches of aluminum with a quarter-inch drill in only seconds instead of minutes,” said Chastenay. “The speed, rigidity and through-spindle coolant blasts chips out of the hole. We handle tight-tolerance holes and slots at ±0.0002 in with great repeatability and don’t spend valuable time making constant adjustments. We could do this on our other equipment, but it takes much longer due to more machining passes and slower feed rates.”

The results on the PS95 are reflected in its part costs. “By reducing our cycle times and achieving better quality, we passed along savings from those efficiencies to the customer. In fact, on parts transferred to the PS95 we have had a 10 percent decrease in cost. Now we bid jobs that we couldn’t do before, and customers are coming back,” explained Chastenay. “We learned that if you don’t invest, you will lose bids on jobs you quote. With the efficiencies gained from our PS95, All Axis as a whole is stronger.” The company views high-performance technology as its future and plans to replace older equipment with another PS95 and possibly expand its capabilities by adding a 4th- or 5th-axis table.

All Axis Research & Development LLC, 13 Bowen Street, Claremont, NH 03743, 603-477-8656, www.allaxiscnc.com.

Makino Inc., 7680 Innovation Way, Mason, OH 45040-8003, 513-573-7200, Fax: 513-573-7360, www.makino.com.