Fine Tune That Cutting Process

Take a look through this assortment of new cutting tools and discover how they can reduce your machining costs and improve your precision to whole new levels.

Posted: June 4, 2015

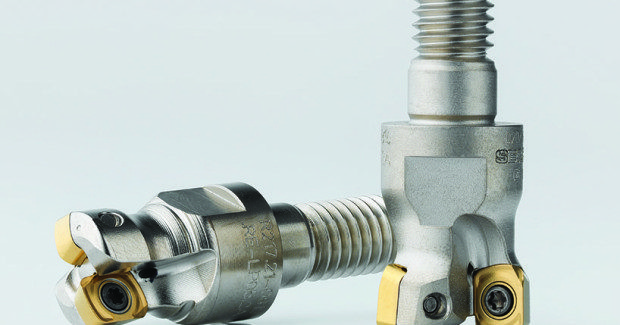

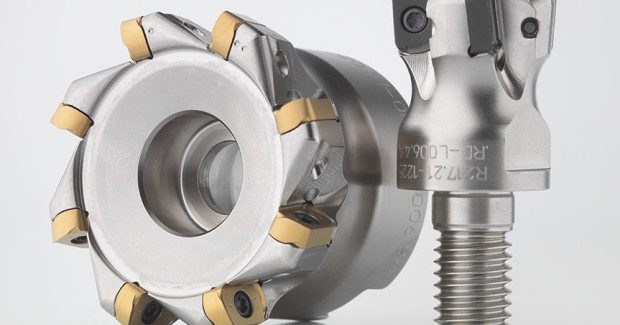

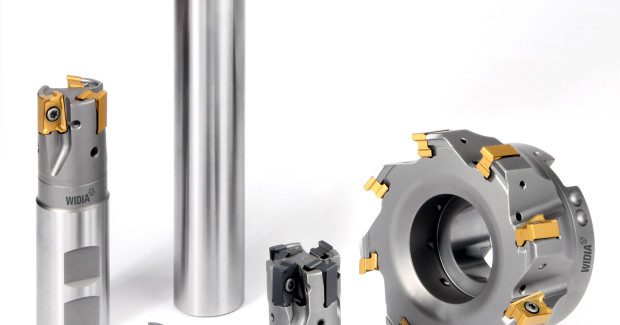

VERSATILITY IN HOLEMAKING

Walter USA, LLC (Waukesha, WI) has enhanced its versatile family of Xtra·tec® Insert Drills with the addition of the Walter Capto™ clamping system and indexable inserts with Tiger·tec Silver® cutting tool material. The Xtra·tec Insert Drills range in diameter from 16 mm to 45 mm, with a depth of cut of 3xD, and feature optimized chip clearance for reliable chip evacuation. They can be used on a variety of materials ranging from steel and cast iron to stainless and difficult-to-cut materials, and can handle chain drilling, sloping, and convex surfaces.

https://youtu.be/M2Ypglxm_3U

Now, the addition of the Capto clamping system provides higher transmission of force via the system’s polygonal interface, high process reliability due to the positive locking of the indexable inserts with TorxPlus screws, and faster tool changing. In addition, its hard-nickel plated surface provides protection against corrosion and wear, and its cylindrical collar promotes straightforward measurement of the tool diameter. The high-performance Tiger·tec Silver® cutting tool material also helps improve the performance of the new drill. The indexable inserts, available in three different geometries and four different grades, have four cutting edges, enabling high cutting parameters and helping to reduce the number of additional operations necessary. The ground indexable inserts are also fitted with a wiper edge, ensuring superior finish.

Walter has also introduced a reduced weight version of its PrecisionMEDIUM B4031.C with the Capto modular toolholding interface. This single-edged precision boring tool is now available weighing 30 percent to 50 percent less than the previous version. While maintaining the same dimensions along with the same properties and performance levels, the new LWS (Light Weight Solution) version weighs just 3.2 kg as opposed to 7.2 kg. Walter is adding the LWS design into its product range with diameters from 90 mm to 110 mm and 110 mm to 153 mm.

For the user this offers several advantages, beginning with easier handling for personnel in the assembly and setting area. Also, these light weight tools are particularly beneficial if a machine’s tool magazine can accommodate limited weight. The design protects the machine and spindle as there is less weight during acceleration and deceleration. Likewise, the moment of force is reduced for the same projection lengths, making it easier to change the tool. Due to its special construction, the tool is also more effective at reducing vibration.

The B4031.C’s light weight Capto interface, with its high clamping force and even force distribution, is completely backlash-free. In addition, it significantly enhances the new tool’s versatility because many of today’s machine tools include a Capto interface as a standard universal interface that is suitable for turning, drilling, counterboring and precision boring, as well as for milling, in both rotating and static modes. With this unique interface system, all machining operations can be performed on lathes, machining centers and turnmill centers.

Walter has also introduced a pair of versatile, high performance and cost-effective taps: the Prototyp TC115 for blind-hole threads and the TC216 for through-hole threads. The taps are able to tackle an array of materials ranging from steel to aluminium (ISO material groups P, M, K, N), save cost by reducing the number of taps needed, and also reduces the investment involved in tap inventory. These two new taps combine superior performance characteristics with their cost-saving versatility. The TC115 blind-hole tap has a 45 deg helix angle for thread depth of 3xD and a C form chamfer. The TC216 through-hole tap features a spiral point for forward chip evacuation and thread depth of 3.5xD. Both have HSS-E bodies and are available with either TiN or vaporized coating. The vaporized variant is a particularly good choice for tough ISO M materials because it increases process reliability, while longer tool life and higher cutting speeds are just some of the benefits of the TiN coating.

Walter USA, LLC, N22 W23855 Ridgeview Pkwy West, Waukesha, WI 53188, 800-945-5554, www.walter-tools.com/us.

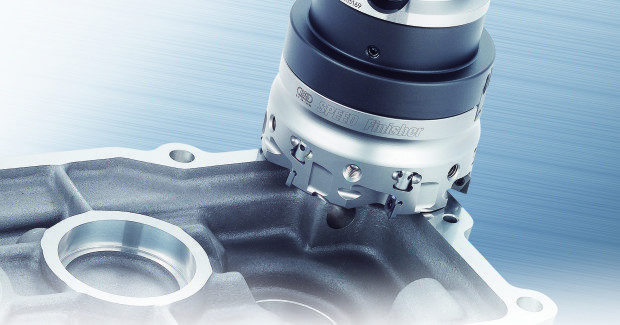

MIRROR FINISHES – FAST

The benefits of BIG Kaiser Precision Tooling Inc. (Hoffman Estates, IL) premium tooling play out with the new BIG Daishowa Speed Finisher face mill for aluminum or cast iron. Its cutting edges are easily adjustable to within 1μm of each other, offering mirror-like finishes through maximum speeds up to 20,000 rpm. The Speed Finisher allows for ultra-fast cutting height adjustment through simple construction. After clamping the insert, the finely-pitched lifting screw lifts up the insert directly by revolving the lifting nut from the side. An exclusive presetter is optionally available to further reduce adjustment time and enhance adjustment accuracy.

The low-profile cutter body enhances the cutter’s rigidity while minimizing vibration and distortion. This, in turn, minimizes height differences in the machined surface. And reduced mass means lighter weight, allowing it to perform even on small machine tools, like those with BBT30 spindles. The Speed Finisher features metric pilot holes of Ø22 mm for the Ø50 mm and Ø63 mm cutters, and Ø27 mm for the Ø80 mm cutter. Coolant is directly supplied to the cutting edge when used in combination with the Face Mill Arbor-Type FMH, making the Speed Finisher especially effective in avoiding built up edges in aluminum.

BIG Kaiser Precision Tooling Inc., 2600 Huntington Blvd, Hoffman Estates, IL 60192, 888-866-5776, 847-228-7660, Fax: 847-228-0881, [email protected], www.bigkaiser.com.

MORE PARTS PER EDGE = MORE EDGE FOR PARTS

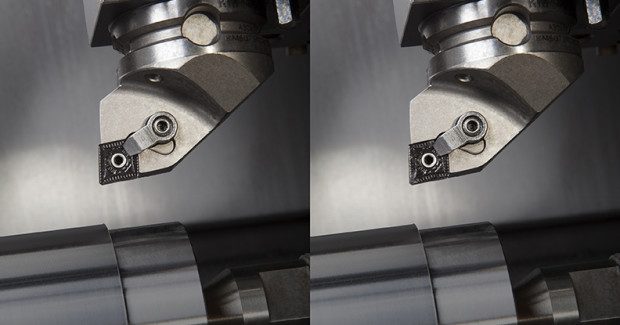

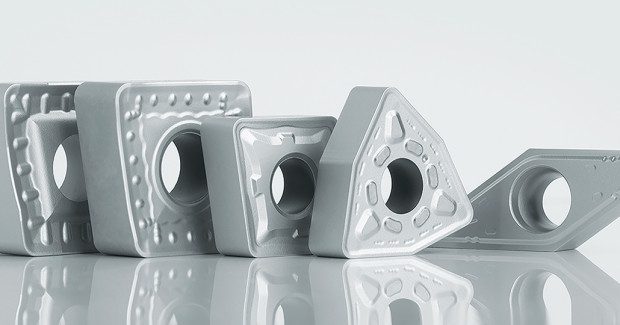

With significantly longer tool life and improved edge utilization in field tests, the newly launched Beyond Drive™ portfolio of cutting inserts from Kennametal Inc. (Latrobe, PA) are being called the new gold standard for turning. Adding a new titanium oxy-carbonitride outer coating (TiOCN) not only increases wear- and abrasion-resistance for lower temperatures and longer tool life, its bronze color is an effective wear indicator as opposed to black-surfaced inserts. Where inserts had been thrown away early in favor of safety because of poor wear identification, operators are now reporting notably longer service life per edge, even in aggressive environments. Depending on the application, field tests are showing up to 30 percent more parts per edge.

Beyond Drive is an entire portfolio of new grades and geometries that emphasize ease of selection and use across work materials and turning conditions. Specific customer demands addressed by these inserts include reduction of notch wear in demanding applications and reduction of crater wear in difficult materials, all while improving wear identification. They are specifically designed for leveraging improved performance and longer life in many critical turning tasks across steels, stainless steels, cast irons, and high-temperature alloys. By cutting costs, avoiding waste, and producing many more higher-quality parts per cutting edge, manufacturers in transportation, energy, general engineering, and more are taking a significant leap forward in productivity and increased capacity.

For example, the MR (medium roughing) insert has a high positive rake angle that works with the smoothly curved cutting edge to reduce cutting forces and extend tool life. In terms of chip flow, it’s like nothing ever seen before, according to Kennametal turning expert Lothar Unglaub. Indexable double sided inserts are subject to high cutting forces, and are commonly seen as less stable. MR’s rake profile without the points of load concentration results in an extremely stable insert body, despite the high positive rake. Even with high depth-of-cut applications, turning processes are safer and more stable, ensuring lower load on the machine tool and workpiece. MR inserts also feature formed-in coolant channels that deliver flood coolant efficiently to the cutting edge. Improved heat control translates into smoother cutting and extended tool life.

Increased stability in Beyond Drive design and performance is added through a KM4X™ spindle connection. Sizing the right spindle connection with the right machine tool helps optimize the productivity of the entire system. The combination of the KM4X system’s high clamping force and interference level leads to a robust connection and extremely high stiffness and bending capacity for greatly improved performance. KM4X overcomes the limitation on bending capacity present in other connections, allowing maximum available spindle power and torque to be utilized in critical operations like turning of high-strength materials. The KM4X connection is capable of performing to the machine tool’s full potential to drive the most out of the cutting edge. Combined with the latest Beyond Drive portfolio, turning can be far more productive and cost-effective.

Another advantage is running dry, where Beyond Drive performs very well. Coolants can cost a lot of money and add processing and disposal concerns. Even in very aggressive turning environments involving external scale or heavy, interrupted cuts, Beyond Drive is showing increased performance. For example, in one test for a plant producing cast iron transmission components, with no change in feed, spindle speed, or depth of cut, Beyond Drive completed 325 pieces per cutting edge compared to 200 pieces for the plant’s current inserts. Not only was this a phenomenal increase in parts per edge, projected machine hours freed per year totaled 125 while the number of inserts required per year dropped from 813 to 500.

A stronger supply chain that gets more parts to market reliably is the foundation of a healthy and growing manufacturing industry. Beyond Drive is a truly exciting development that promises more higher-quality parts per shift, more efficient machine utilization, and longer tool life.

Kennametal Inc., 1600 Technology Way, PO Box 231, Latrobe, PA 15650-0231, 724-539-5000, www.kennametal.com/BeyondDrive.

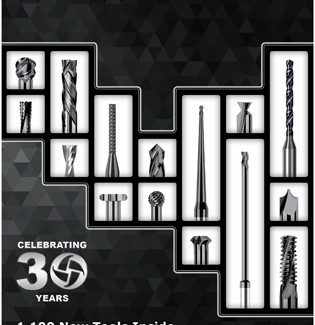

INNOVATIVE SPECIALTY CUTTING TOOLS

Harvey Tool Company, LLC (Rowley, MA) is pleased to announce the release of its 30th Anniversary Spring 2015 Catalog. With a legacy of making specials into standards and providing the widest and deepest selection of in-stock innovative Miniature End Mills and Specialty Cutting Tools, Harvey introduces over 1,100 new tools. New sizes and coating options have been added to over 40 different products, including hundreds of new tools. Along with over 12,000 standard tools stocked, the new product development team has engineered eight new Miniature Specialty End Mill lines, including: