Breakthrough In Aluminum Face Milling

This machine shop halved its cycle time on producing diesel engine manifolds and rocker arms, saved $300,000 a year in machining costs and sidestepped a $500,000 capital expenditure. All with one tool.

Posted: June 4, 2015

If you’re looking to radically improve aluminum face milling capacity, take a look at what a difference a breakthrough cutter has made at Ward Production Engineering (Fort Wayne IN). Long story short: cycle time halved on diesel engine manifolds with a 60-75,000 annual volume and rocker arms with a 15,000 annual volume. On these two parts alone Ward is saving $300,000 a year in machining costs and has averted a $500,000 capital expenditure.

With a 6 in Tedimill cartridge-type PCD face mill from Ingersoll Cutting Tool Company (Rockford, IL), the shop mills the manifold at 10,000 sfm and 427 ipm in a single 5 mm (0.200 in) pass. That’s more than twice the speed and feed as before – on an interrupted-cut workpiece – and twice the depth of cut. The finish pass is the customary 0.010 in to deliver a 3.2µ finish. Yet tool life improved as well. “We expected 50 percent longer edge life, but can’t tell for sure yet. The original edges are still running fine after three months of 24/5 use, and surface finish remains well within specs at 3.2µ,” says foreman Gary Short. “By this time with the previous tool, we’d have had to change inserts at least once.”

Operating an aluminum foundry and an 85-man machine shop running 24/5, Ward is an integrated second tier automotive parts supplier. About 85 percent of the machining workload is face milling, so any improvement in that operation sends good ripples all down the line. What drove Ward’s search for a better face milling solution was an eight percent jump in order volume for the manifold that came through in late 2013. With the previous cutter on two Mazak Cadet horizontal CNC mills, the shop was running flat out. Any speedup attempts led to excessive tool wear and the real risk of tool wrecks taking out $1,900 cutters. The manifold measures about 30 in long, 5 in high and 10 in wide and weighs about 18 lb in the finished condition. Machining the piece involves extensive interrupted cuts.

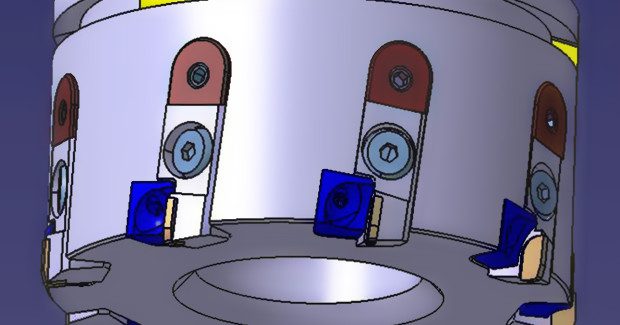

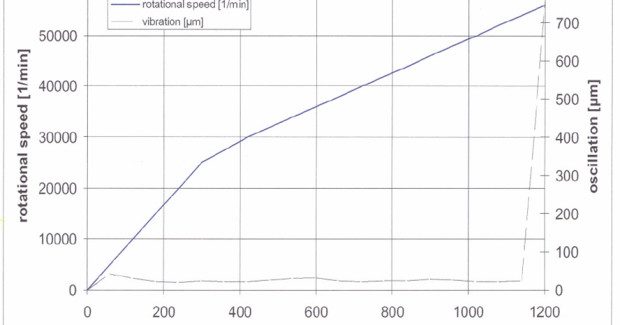

“We thought we’d have to add a $500,000 CNC machine to handle the increase,” recalls Short. “But we got the same result with the Tedimill retooling and adding a Saturday shift instead. I’d take that deal any day.” He learned of the new cutter at a tooling seminar in Rockford that included a demo of a revolutionary aluminum face mill developed by Ingersoll’s European sister company in the IMC Group, Italian Technical Diamond Company. Tedimill is the first face mill in the world to be certified for 16,000 sfm speeds right out of the box. The demo included a video of the tool making chips at 54,000 rpm in a test setting on the highest-speed spindle in the world.

In the demo, the Tedimill, with brazed PCD cartridges running in the high speed machining (HSM) mode, completed an aluminum auto part much like the Ward workpiece in half the time as with next-best available PCD face mills. And it left a chatter-free finish when run at 16,000 rpm. Short asked presenter Craig Bastian to visit him in Fort Wayne to conduct an on-site live trial on the manifold job. It was planned as essentially a drop-in retooling to run on the machine they presently use, a Mazak 6800 horizontal CNC with a 10,000 rpm spindle – which is nowhere near the limits of the tool.

When Bastian visited Ward along with Ingersoll field rep Jim Plummer, he recognized the machine’s spindle speed limitation and recommended much higher parameters. In fact, he recommended starting at triple the feed rate, double the spindle speed and double the cutting depth over previous settings. “Let’s not forget, it takes a very strong cutter and very rigid insert cartridges to mill at 57,000 rpm chatter-free and without flying apart, so we were certain that the Tedimill could survive those higher machining rates,” noted Bastian. He and Plummer also recognized that the Mazak Cadet is a beefy machine built more to handle steel parts, so they weren’t worried at all. But Short wasn’t so sure. He was concerned about wrecking the cutter or blowing the cartridges, especially because of the interrupted cuts. He joked with Bastian about guaranteeing the tool.

Instead, they started conservatively, only to work back up to Bastian’s original recommendations. Now all face milling on the manifold is completed in 58 seconds, down from 1:51 with the previous positive-rake cutter using either PCD or carbide inserts. Ward had tried both.

At that rate, Short did the math to make the case for management and networked with Mitch Bair at Ingersoll distributor Specialty Tool LLC (Fort Wayne, IN) to nail down local stocking of the special TEDI inserts. On only the manifold and rocker arm, he projected a four-week return on investment for the Tedimill, even though the package cost $20,000, about twice as much as the previous tool. To any pencil pusher, payback in less than a month with a robust MRO supply chain for process security is a no-brainer.

Now Ward easily meets the order increase for manifolds by retooling the two Mazaks with Tedimills and adding a Saturday shift. “That’s certainly more cost effective than adding a $500,000 machine to the fleet,” he says. Short added that, based on what he’s seen, they could safely push the machining rates still further. Ward has since tooled five more machines with Tedimill 4 in and 6 in diameters, essentially standardizing on it for all face milling. The average margin of improvement on all jobs has been consistent: about 2 to 1 in cycle time, and 50 percednt in edge life.

Unlike any other PCD cartridge mills, the Tedimill features absolutely rigid cartridge seating, positive-rake presentation and coolant delivery directly to the cutting edge. Insert corner radii are replaced by small 45 deg chamfers to reduce axial cutting forces. Tedimills are available domestically with either aluminum or titanium cutter bodies: Ward uses 6 in Tedimills with aluminum bodies and 4 in cutters with titanium bodies. “To me, the biggest difference is the much more rigid insert cartridge seating that keeps everything stable at these higher machining rates,” adds Short. “We’ve even accidently taken a 14 mm deep cut and it didn’t harm the tool at all. The worst that ever happened was one fractured insert.”

Ward Corporation, 642 Growth Avenue, Fort Wayne, IN 46808, 260-426-8700, www.wardcorp.com.

Specialty Tool LLC, 6925 Trafalgar Street, Fort Wayne, IN 46803, 800-648-9918, Fax: 260-749-5890, www.specialtytool.com.

Ingersoll Cutting Tool Company, 845 S. Lyford Road, Rockford, IL 61108-2749, 815-387-6600, Fax: 815-387-6968, [email protected], www.ingersoll-imc.com.