All Bent Into Shape

Here is some of the newest equipment and tooling used to bend sheet metal and plate steel.

Posted: June 3, 2015

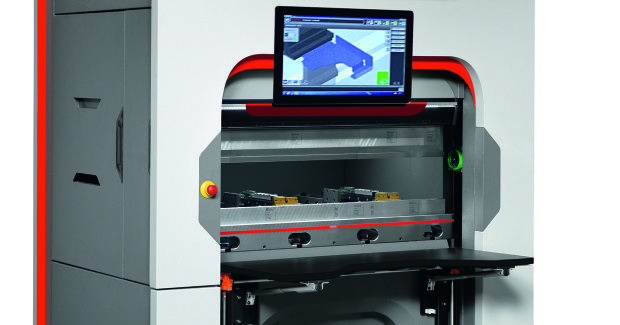

The Xpert 40 is the fastest press brake of its size on the market: typical press brake production is 622 bends per hour (BPH), typical high dynamic electric or hybrid press brake production is 916 BPH, Xpert 40 production is 1,028 BPH. With its flexible tool selection and a press capacity of up to 44 U.S. tons, this machine offers a wide range of applications from thin and thicker materials, and the ultra-high performance back gauge system, with up to a 6-axis, enables the cost-efficient production of highly complex sheet metal shapes. High operator efficiency is also achieved through ergonomic design and individually adaptable workspace. Noteworthy is the process-controlled drive unit which reduces power consumption by up to 30 percent!

Bystronic Inc., 200 Airport Road, Elgin, IL 60123, 847-214-0300, Fax: 847-214-0299, [email protected], www.bystronicusa.com.

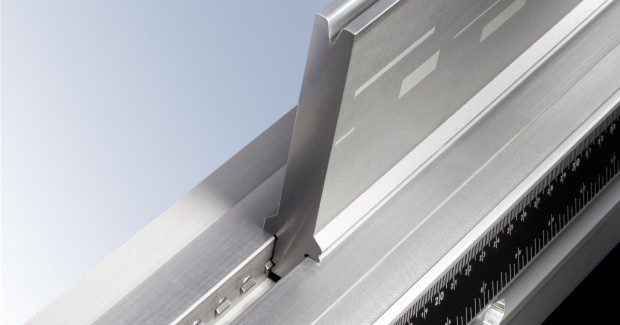

ABSOLUTE DIE ALIGNMENT

Wila USA (Hanover, MD), the U.S. subsidiary of Wila bv (Lochem, The Netherlands) introduces their new V-Lock® System that consists, in part, as a new self-seating groove that has been added to the tang of all Wila New Standard®, American, and American Vintage® Dies with V-openings of 2.362 in (60 mm) and smaller. This feature, combined with a new generation of clamping pins that will be provided with all Wila Crowning Systems and Bottom Tool Holders with hydraulic die clamping beginning in the second half of 2015, provides several new benefits, including absolute die alignment along both the X and Y axis of the press brake and positive clamping of individual die sections so that even the smallest sections cannot be inadvertently moved out of position as is common during sheet handling.

V-Lock also improves the performance of press brakes equipped with robotic tool loading and unloading by preventing the movement of individual die sections during bending operations and providing absolute alignment of all die sections along the X and Y axis. All Wila dies equipped with the V-Lock feature can be used in hydraulically and manually operated die holders with and without V-Lock clamping technology. Wila will be adding its new V-Lock System to its products at no additional cost to its customers.

Wila USA, 7380 Coca Cola Drive, Hanover, MD 21076, 443-459-5496, Fax: 443-459-5515, www.wilausa.com.

PRESS BRAKE TOOLING FOR NEARLY ANY METAL BENDING

Mate Precision Tooling (Anoka, MN) has launched a new line of press brake tooling punches and dies for press brakes configured with European Precision Style and Wila Trumpf Style tooling. This press brake tooling is manufactured with renowned exacting performance standards and backed by a legendary 100 percent satisfaction guarantee that has set the standard in CNC punch press tooling and laser consumables needs for more than 50 years. Now users can rely on the same level of sophisticated technical support, unsurpassed product quality and responsive customer service for press brake tooling. This press brake line includes an expansive array of punches, dies, standard specials, specials and accessories, available in segmented, full-length and half-length sizes to suit nearly any metal bending application. This precision ground tooling is manufactured from premium alloy tool steels, with the wear surfaces of the punches and dies induction hardened for extra durability.

Mate has created a legacy in providing an exceptional user experience with the powerful combination of outstanding products, in-field technical support and knowledgeable customer service. More than 30 sales engineers across North America draw on their extensive field experience to support their users. Since many worked as fabricators themselves, these engineers routinely help customers develop the most cost-effective, practical solutions for their metal fabricating needs on-site. Customers work with just one sales engineer for all products, which helps to improve efficiency for the fabricator. The sales engineers are backed by a team of in-house customer service representatives and applications specialists. Mate’s extensive breadth of press brake tooling is now available for shipment.

Mate Precision Tooling, 1295 Lund Boulevard, Anoka, MN 55303, 763-421-0230, Fax: 763-421-0285, matepressbrake.com.

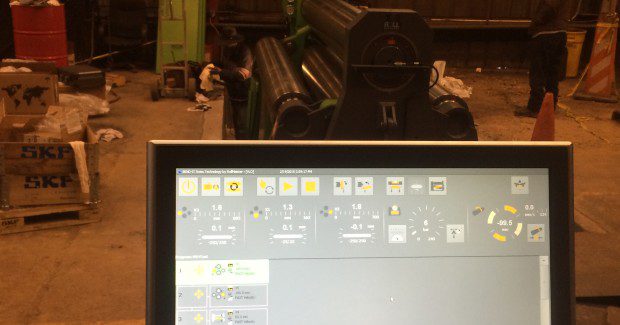

MANAGE NETWORKED METAL BENDING OPERATIONS

As Industry 4.0 becomes increasingly relevant to the sheet metalworking industry, LVD Strippit (Gullegem, Belgium) has responded with a technology that gives shop managers critical production information in real time. TOUCH-i4 is an industrial strength Windows-based tablet that provides an overview of the entire fabrication workshop by generating and presenting live information needed to manage networked LVD laser, punching and bending machines.

The real-time TOUCH-i4 system collects information from LVD Strippit machines and a centralized CADMAN database to offer insight and flexibility to daily operations. This information can be viewed and managed wirelessly on the shop floor with TOUCH-i4, allowing the user to make informed decisions based on lead-time, cost, technology and individual machine workload. Detailed information includes KPI history with full visibility and diagnosis of workshop performance including OEE analysis, future workload with overview and plan future workload by overall capacity, by technology and by individual machine and sort and validate, TOUCH-i4 can be used to help sort and validate parts allowing users to streamline production orders ready for the next operation.

Strippit, Inc. 12975 Clarence Center Road, Akron, NY 14001, 716-542-4511, Fax: 716-542-5957, marketing@strippit.com, www.lvdgroup.com.

BENDING THICK STAINLESS PLATE

Kersten Europe GmbH (Steisslingen, Germany) produces cones and cylinders for offshore projects, architectural structures, machine constructions, fuel depots and more with their PB3-18-10 plate bending machine from Schwarze-Robitec GmbH (Cologne, Germany). The toll manufacturer specializes in plate and section bending by using the powerful PB3-18-10 plate bender, which has a high level of torque, a cone bending device and hardened rollers for bending stainless steel plates.