A New Wave of Metalworking Fluids

The strategy behind Resource-Efficient Manufacturing is to introduce new approaches to metalworking fluids that dramatically reduce resource use.

Posted: June 19, 2015

Metalworking lubricants represent a very minor part of the costs in a metalworking process, typically less than one percent, but the importance of correct fluid selection can have a direct impact on the competitive edge of a given machining application and trigger a multiplier effect on operational costs. For these reasons, the metalworking fluid industry is already playing an essential role in Resource-Efficient Manufacturing (REM), which involves doing more with less and finding viable reuse and recycling technologies to conserve materials, meet stringent environmental targets, and increase operational competitiveness.

WHAT IS REM?

REM is a strategy that seeks to reduce the environmental footprint of an industry by doing more with less and finding viable reuse and recycling technologies to conserve material inputs. This is all about good ecology that is good for business as well. Numerous studies show the positive correlation between resource efficiency and REM has become a key strategy for companies to save money and reduce the environmental impact of their operations.

The REM concept is well established in the EU, where companies are given targets by government regulatory groups. It is taking root among large-scale manufacturers across the globe and has introduced a wave of new thinking, technologies, and process-influencing manufacturers that provide smart, sustainable solutions to create resource efficiency that meets the challenges of sustainable production.

One global leader in metalworking fluids, Quaker Chemical Corporation (Conshohocken, PA), is putting sustainable chemistry into action by helping shops address issues of energy efficiency, waste reduction, safety and durability through new approaches to coolant and cleaner use with their high performance QUAKERCOOL® 700 Series metal removal fluids and their eco-efficient 2PAQ™ dual phase technology.

RETHINKING COOLANT AND CLEANER USE

Incremental improvements in machining operations costs and sustainability can be obtained through conventional controls, such as closely monitoring and upgrading to more bio-stable coolants to extend sump life. But to achieve dramatic ecological and economic benefits, a completely new way of working is needed.

In an aligned effort, a new approach to coolants and cleaners has been developed known as 2PAQ, a dual phase technology designed around a lubrication phase and alkaline phase which will perform a wide range of machining and grinding operations on cast iron, steel and aluminum alloys. The fluid, when used as a cleaner, can also be added to the coolant tanks for top-ups – therefore it is used twice. This approach can result in as much at 90 percent reduction in waste generation, showing savings in water consumption, capital investments in wastewater treatment equipment, and energy and wastewater treatment costs.

Laurent Ilievski, a product manager for Quaker European Operations in France, is a global expert on cutting and grinding fluids with 20 years experience in the field. He talks about the 2PAQ approach to coolants and cleaners. “Most manufacturers operate on largely linear use of materials – they employ a process where they inventory dedicated coolants and cleaners, they use them, and then dispose of them. We knew to get the resource reductions our customers were looking for, we would have rethink that whole process and change it from start to finish.”

2PAQ includes a compatible, two-part coolant/cleaner that is used for a wide variety of operations. The fluid, when used as cleaner, can be repurposed in the cutting fluid tanks for top-ups – therefore it is used twice. Ilievski says, “The result can be as much as a 90 percent reduction in waste generation. This is dramatic, especially for customers with CNC units connected to large 100,000 liter or 200,000 liter centralized systems.”

The 2PAQ approach has helped shops be both eco-efficient and economically efficient by reducing wastewater quantities, which improve their environmental compliance, and by achieving savings in a number of sources:

- Water consumption is minimized because the cleaners are reused for the makeup of the top-up.

- Energy and wastewater treatment costs are reduced because significantly lower quantities need to be.

- Capital investments in wastewater treatment equipment can be reduced or eliminated.

“One shop was planning to install a larger evaporator,” adds Ilievski. “Once 2PAQ was in place, they not only stopped running their evaporator the equivalent of three months in a year – saving the related electrical expenses – they eliminated the need for a new evaporator.”

Furthermore, 2PAQ has been shown to enhance machining performance, especially in the foaming behavior and stability of the emulsion. “This same shop,” continues Ilievski, “which uses a boron-free version of 2PAQ, added tank-side additives just once during the last year. And this was for maintenance purposes during the summer break. That’s a very significant improvement for them.”

THE ESSENTIALS OF 2PAQ

The 2PAQ concept is based on the versatility of its chemical components and a new way of working. A two-component fluid replaces many (sometimes 20 or more) dedicated fluids that a manufacturer uses for machining operations. It is formulated in different solution ratios of the alkaline and oil phases mixed into water to prepare emulsions – to meet a wide variety of different coolant/cleaner needs.

For example, for operations that require higher levels of lubrication, the “oil phase” is used at a higher ratio to provide a more robust, high-performance micro-emulsion for machining cast iron, steel, and aluminum alloys. 2PAQ’s versatility also allows it to be used as a process cleaner. When the cleaner solution becomes saturated, instead of being disposed of, it is added to the coolant tank to aid with volume control (“top-up”).

2PAQ currently runs in 37 central systems globally – some for nearly five years – in the automotive and heavy equipment manufacturing industries, as well as their component suppliers for brakes, engines, gears and more. Customers have achieved dramatic annual savings. For example, one major global manufacturing subcontractor of innovative braking systems for the automotive industry was looking to improve machine performance, reduce overall cost, and reduce waste of machining fluids. 2PAQ was installed in four central systems in subcontractor’s facility.

The change brought a quantified savings of approximately $73,800 in fluid related costs to the largest of the central systems, along with documented annual cost savings of $47,800 to $51,900 in waste treatment; $1,360 in biocide additions; and $24,600 in top-ups.

What does the conversion to 2PAQ entail? “Generally there are limited investments needed to make the conversion to 2PAQ,” says Ilievski. “Many shops are already equipped with large centralized systems and the associated equipment. However, some may need to invest in equipment to recirculate the cleaners into the central systems.”

Can shops top off their existing system with 2PAQ products or do they have to run down or drain the current system? “You don’t have to drain the system or waste what is in inventory as long as the existing material is chemically compatible,” explains Ilievski. “We can help run tests to ensure the current products are compatible with 2PAQ. So far, we haven’t experienced any compatibility issues with a customer’s current systems.”

How do shops learn how to create solution ratios for the different phases and for different applications, metal types, etc.? “Creating the proper ratio is not difficult and the process is not really different from choosing an appropriate coolant,” notes Ilievski. “Our technical team works together with the shop – providing training and support to ensure the proper makeup of the emulsion. They are generally on-site to manage large centralized systems. Lab tests are available when needed.”

MACHINING AND GRINDING

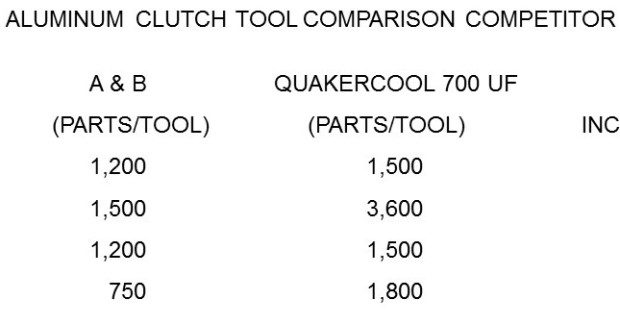

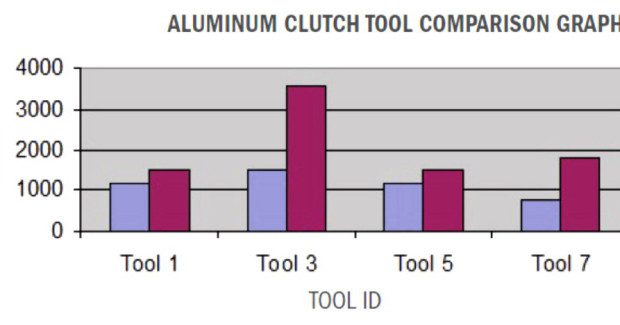

A leading supplier of engine and drivetrain components for a global major automotive manufacturer was trying to optimize their process related to the metalworking fluid they used in producing automotive parts for light trucks, SUVs and transmission components. They were looking to improve tool life, overcome poor operator acceptance, reduce high applied costs and eliminate tacky residues.

QUAKERCOOL 700 UF lubrication technology was introduced after an extensive investigation of operational parameters and review of process challenges was conducted. This mineral oil-free advanced lubrication fluid is ideal for exotic machining and grinding operations on titanium alloy, compacted graphite iron (CGI), stainless steels and other high nickel-chrome alloys, and is also used for critical surface finish machining of cast and wrought aluminium.

This fluid is based on a microemulsion of proprietary synthetic components that effectively resists microbiological growth and contains no chlorinated compounds, formaldehyde release agents, boron, MEA or secondary amines to help meet local requirements. Along with providing superior tool life, excellent short-term corrosion protection and a lower vapor pressure technology that results in an operator friendly environment, it will not stain automotive or aerospace aluminum alloys at recommended concentrations and it rinses clean, leaving an excellent nontacky residue. Its concentration range is recommended to be between 6 percent to 10 percent, depending on the type of operation and make up water hardness that is typical between 50 ppm to 300 ppm.

At the end of the trial, the shop determined that, at 7 percent concentration, they could improve tool life by more than 25 percent over their competitor’s baseline. The low operating pH of this fluid gained high operator acceptance, and its lubrication did not leave those undesired tacky residues that the operators did not like handling (see sets of results from Figures 1-3).

Quaker Chemical Corporation, One Quaker Park, 901 E. Hector Street, Conshohocken, PA 19428-2380, 610-832-4000, quakerchem.com.