A Boring Revolution

Shops in search of process improvements will find the increase in process speeds, higher quality, less tool maintenance and lower operating costs generated by this innovative tooling system anything but boring.

Posted: June 4, 2015

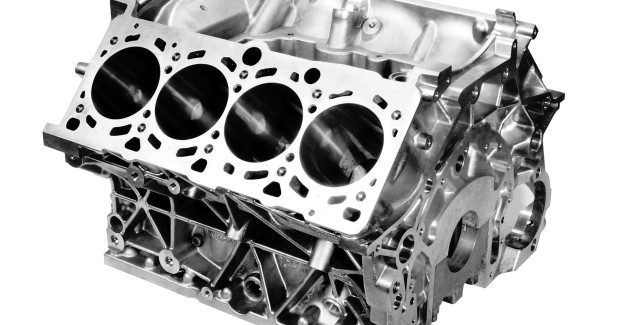

Precision boring is a vital process in manufacturing many critical components. The accuracy and finish of a multi-journal crank bore in an engine block relates directly to power and fuel efficiency, and the time it takes relates directly to the engine company´s profits. Precision bores in numerous engineered components are essential to critical performance metrics. Such bores must meet critical tolerances, but the downside is that precision boring can be costly and time-consuming, with a small mistake or error resulting in the scrapping of expensive parts. One response to this is a geometric and asymmetric line boring bar system from Kennametal Inc. (Latrobe, PA) that is being termed a revolution in the process by delighted users.

By definition, boring (as opposed to drilling) is a machining process in which internal diameters are made in true relation to the spindle centerline. This process is most commonly performed with the workpiece held stationary and the cutting tool both rotating and advancing into the workpiece, although boring is also done with the cutting tool and the workpiece being adjustable. Common applications for boring include the enlarging or finishing of cored, pierced, or drilled holes and contoured internal surfaces. Related operations sometimes performed simultaneously with boring include turning, facing, chamfering, grooving, and threading.

Now envision a small engine block with five in-line journals requiring crank bores. Conventional thinking for a multi-journal finishing assignment, for example, involves a multi-blade guidepad reamer with the following suggested process (here designated as Option 1.0):

- A pilot reamer finishes the first journal.

- The multi-blade reamer is fed in and semi- and final-finishes journals 2 through 5.

- The reamer is then retracted.

The advantage of such a process is that it lends itself to use on CNC horizontal or multi-axis machining centers and does not require a dedicated boring machine with dedicated fixtures. However, depending on the size of the workpiece, the machine tool must be of sufficient rigidity or quality can fall off dramatically. Also, feed-in and feed-out of the reaming tool over finished bores must be done slowly and precisely or retraction marks and/or damage to the cutting edges will occur.

Another general option for machining this kind of bore is line boring (Option 2.0). The basic issue to be solved in this option is how can the cutting blades and the tool´s guide pads pass through unfinished journals with smaller hole diameters? CNC machine tool builders have responded to this quandary with using conventional line boring bars and “counter-bearing” capabilities on their equipment. The process looks like the following:

- The workpiece area of the machine tool lifts the cylinder block up.

- The line boring bar is fed through the component into a bearing at the opposite end.

- The cylinder block is adjusted down and clamped.

- Crank bores are semi- and final-finished.

- The cylinder block is lifted up and the boring bar retracted.

The process speeds up feed-in and feed-out and, because the tool is supported on both ends, the geometric quality of the finished bore is improved compared to reaming in Option 1.0. On the downside, lift functions require special fixturing and CNC control, and the required counter-bearing on the fixture makes any additional back-side machining impossible. Multi-axis machine tools with tilting worktables and/or tilting spindles, together with more evolved boring bars, contribute to Line Boring Option 2.1 with expandable guide pads, where the process evolves to the following:

- A pilot reamer is fed in and finishes journal 5.

- The component (or machine table) gets rotated 180 deg.

- The machining center X-Y axis is adjusted to feed the boring bar in off-center.

- The boring bar with guide pads is centered into journal 5.

- Guide pads are expanded.

- Journals 1 through 4 are semi- and final-finished.

- Guide pads are fed back in.

- The boring bar is retracted off-center.

Option 2.1 uses the multi-axis adjustability of the machine tool. It retains the advantages of Option 1.0 by eliminating the need for any lift function or counter-bearing and Option 2.0 with support on both ends of the tool. The disadvantages are that the complex internal mechanics of this type of boring bar are costly and can be difficult to handle. Insufficient lubrication use can damage sensitive internal mechanics, and if not monitored exactly, the tool can jam or hook in the workpiece and cause damage to the machine, fixture, tool, and part.

AN ASYMMETRIC SYSTEM

In collaboration with a major automotive manufacturer´s engine block operations, the engineering staff of Kennametal has advanced the boring function by introducing Option 3.0 – asymmetric line boring, a geometric leap forward that accentuates the advantages of reaming and line boring while virtually eliminating the disadvantages of both.

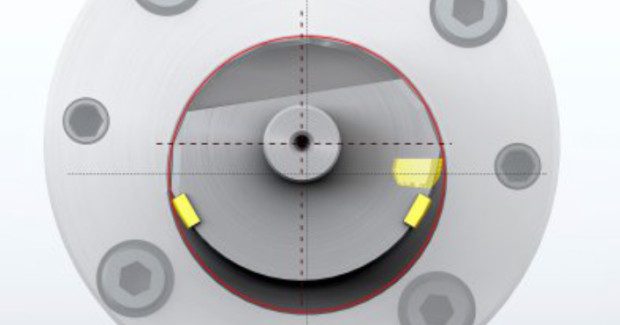

As with most advanced systems, the principle at the foundation is quite basic. Normal guide diameters are of full material or build of three or more guide pads, providing no degree of freedom from the bore wall while feeding in and out. This system supports on guide pads in a setup similar to a typical guide pad reamer, but the guide pad, normally located 180 deg to the cutting edge, was rotated so the resulting design provides freedom to enter and exit the guide part even passing through the raw bores. This geometry allows feeding the bar through raw bores on an eccentric path. The process, then, looks like this:

- A pilot reamer is fed in and finishes journal 5.

- The component (or machine table) gets rotated 180 deg.

- The asymmetric boring bar is fed in off-center using the machining center´s X-Y axis.

- The tool is moved to the center and finishes journals 1 through 4 simultaneously.

- The tool is retracted off-center with fast feed out.

Such asymmetric line boring retains all the advantages of previous line boring efforts – high-quality precision bores, support on both ends of the tool, while no expensive lift functions, obstructive counter bearings or critical mechanisms inside the tool are needed. It also adds the fact that complete feed-in and feed-out moves can be done at increased feed rates on conventional machining centers, adding efficiency to the process.

The indexable inserts offered with this eccentric boring bar solution are also advanced. High-precision RI8 inserts have eight cutting edges with pre-defined back taper, which allows for high feed rates. Diameter can be adjusted to the precision of one micron. The high clamping force provided by the conical clamp screw avoids any settling effects. Both the inserts and the asymmetric boring bar are designed so the inserts clamp directly into the boring bar body. This eliminates the need for cartridges and the additional tolerances and space they require.

In short, this asymmetric line-boring solution increases machining robustness, process speeds, and reduces tool maintenance and handling, all while being compatible with CNC machining centers – a solution any manufacturer in search of process improvements will find anything but boring.

Kennametal Inc., 1600 Technology Way, PO Box 231, Latrobe, PA 15650-0231, 724-539-5000, www.kennametal.com.