Yaskawa Motoman Enters License Agreement with NSK

Yaskawa Motoman now has exclusive rights in the Americas for NSK ultrasonic cutting and deburring machines with 3D profiling.

Posted: May 8, 2015

The Motoman Robotics Division of Yaskawa America, Inc. (Dayton, OH) has entered into a license agreement with Nihon Shoryoku Kikai Co., Ltd (NSK). Under the terms of this agreement, Yaskawa Motoman will have exclusive rights in the Americas for the technology, manufacturing and sales of NSK ultrasonic cutting and deburring machines with 3D profiling.

This patented cutting technology replaces conventional trimming methods such as waterjet cutting and laser cutting for non-metallic materials including plastics, fiberglass and non-woven fabrics. The technology is ideal for automotive and recreational vehicle part manufacturing such as:

- Automotive interior trim including headliners, carpet, instrument panels, door panels, rear deck

- Injection molded parts for motorcycles, ATVs, snowmobiles

- Semi-truck fairings, boats and seating

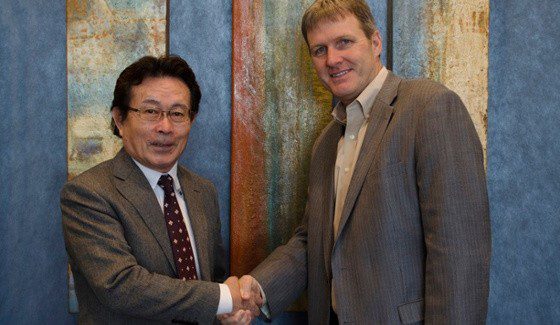

“We are pleased to announce this multi-year agreement with them for licensing our patented ultrasonic cutting and trimming technology in North and South America,” stated Norio Tanaka, the president of NSK. “We have been working with Yaskawa Electric Corporation in Asia for many years, and this represents a natural geographic expansion for our product line.”

Ultrasonic cutting offers a unique, environmentally-conscious approach with numerous advantages including:

- Waterless operation and clean up

- Quiet operation

- Energy efficiency

- Limited dust

- Lower consumable costs

Yaskawa Motoman trimming workcells will feature a high-speed Motoman® robot fully integrated with NSK ultrasonic cutting tool and milling head. The cutting tool features a HSS carbide blade vibrating at 40 kHz. The workcells will be available in a “part-to-process” or “process-to-part” configuration.

“Our partnership with them will expand our application capabilities in automotive tier and other non-metal manufacturing environments,” stated Steve Barhorst, the president and chief operating officer of Yaskawa Motoman. “Our goal is to provide solutions that are environmentally friendly, as well as increase productivity and improve product quality. Their ultrasonic cutting technology, integrated with a Motoman robot, will deliver outstanding ROI to our customers.”