Safeguarding the Shop

A review of some of the latest machine safeguarding devices and related shop safety systems designed for protection of both employees and equipment in the workplace.

Posted: May 1, 2015

ALARMS, GUARD RAILS AND MORE REDUCE ACCIDENTS AND OSHA VIOLATIONS

An open gate on an elevated mezzanine level is a serious safety concern that could result in an employee falling and sustaining severe injury, including broken bones, lacerations, or even death. For every elevated application where an open gate situation could occur, an early warning device such as the EdgeAlert™ Open Gate Alarm system from Wildeck, Inc. (Waukesha, WI) could make all the difference. When properly installed, the EdgeAlert alarm will signal an open gate condition with a highly visible flashing light and a loud audible alarm. According to Hubert A. Schlegel, the director of marketing at Wildeck, “This is a must-have device that can help protect personnel, increase facility safety and reduce the costs associated with injuries and lost time accidents. Every elevated gate that could inadvertently be left open should have an EdgeAlert alarm installed today!”

This alarm is easy to operate and can be installed on new or existing swing gates, slide gates, tilt gates or scissor gates. It includes a 120 VAC plug-in power supply and can also be powered by four long life alkaline “D” cell batteries, which are not included with the device. A Single-Pole, Single-Throw 30V, 2A, 60W Relay Output is provided for connection to other alarms or safety controls. A dual-channel processor system is self-monitoring and will display a “fault” signal if a sensor or wiring problem is detected. For maximum visibility at elevated and ground levels, amber-colored LED lights are located on the front and back of the alarm enclosure.

When a gate is being used for daily activities, workers may choose to silence the EdgeAlert alarm for 120 seconds by pressing the “Snooze/Acknowledge” button. Once an open gate has been closed and secured, users can reset the alarm by pressing the “Snooze/Acknowledge” button, or simply opt for the automatic reset mode. “This patent-pending system represents our market leadership position as a manufacturer of more safety products and options for storing, lifting, and guarding equipment than any other U.S. manufacturer,” added Schlegel.

The company also provides ValueRail safety guard rail and pedestrian railing products that are precision formed from high-strength steel and painted safety yellow with a durable two-part polyurethane coating similar to an automotive clear-coat finish. A common post design simplifies installation and posts are manufactured using solid structural wide flange beams, providing an economical solution for rail support. The rails use 18 in, 44 in, and 60 in high beams that are protected and finished with an innovative and functional PermaCap™ top cap. Single-, double- and triple-rail lengths are available in one foot increments from 2 ft to 10 ft, providing a wide range of protection options. Anchor bolts and the appropriate rail hardware are included with all post configurations. A Lift-Out Kit is also available that adds pockets to standard posts allowing the user to slide standard rails in-and-out rather than rigidly bolting them to the posts.

Also, the ValueRail Pedestrian Handrail is available in 6 ft sections to separate work zones, control traffic flow, and clearly define walkways around equipment, machinery, material staging areas, in-plant offices, doorways, and many other ground-level applications. In today’s competitive environment, facility managers cannot risk damage to inventory, plant equipment, or personnel from fork truck or heavy cart impact in work areas or loading zones. Protecting these vulnerable spaces couldn’t be easier with the full-line of ValueRail safety guard rail that is available from stock to meet customer needs. When properly installed, these guard rails can help reduce workers’ compensation claims, lower insurance costs, and help pass OSHA safety inspections. Typical ValueRail guard rail applications for accident avoidance include:

- Protection of work areas

- Machine guarding

- Pedestrian walkways

- Fork truck and vehicle traffic lanes

- In-plant offices

- Doorways and stairs

- Loading dock ledges

ValueRail safety guard rail and pedestrian railing products are 100 percent “Made in the USA” and are available on-line, direct-from-the-factory, through the www.valuerail.com website that features the e-commerce, shopping cart technology and security combined with straight-forward navigation that allows any contractor, warehouse manager, manufacturer or other facility personnel to quickly select what they need and purchase it directly with a company credit card. Users can safely purchase ValueRail with a VISA®, MasterCard®, American Express® or Discover® credit card. Applicable sales taxes and shipping charges are automatically calculated and orders are reviewed and confirmed before a credit card is actually charged. An experienced safety products specialist is also available to assist customers Monday through Friday from 8:00 am to 5:00 pm CST at (262) 549-1963, or via e-mail at [email protected].

The company also responds to customer needs for a safer, more efficient multi-level vertical lifting solution for automated conveyor applications with the XpressLift™ Automated VRC. According to Schlegel, “The XpressLift VRC incorporates the latest state-of-the-art components to make it easy to install, easy to maintain, and most importantly, easy to integrate into a customer’s material handling conveyor system.” It is designed and manufactured to meet ANSI/ASME – B20.1 “Safety Standards for Conveyors” and can quickly transfer totes or cartons of material weighing up to 75 lb at speeds up to 350 fpm. Units up to 18 ft high are shipped factory assembled, prewired, and fully tested making integration into conveyor systems fast and hassle free.

The standard “all-in-one” interactive controller features an easy-to-read text display on the front cover of the control panel that aids in commissioning and lift system set-up. Local vertical and horizontal jog control is also provided, along with lift diagnostics to simplify troubleshooting and preventative maintenance. Another noteworthy feature is the closed-loop AC Vector Drive that is mounted directly on the motor at the top of the lift for maximum efficiency and heat dissipation, as opposed to having the drive confined inside an electrical control panel. Additionally, an encoder continuously monitors the motor and controls the braking system for safety and allows ultra-smooth, high-speed lift operation. Carriage stopping is also performed by the drive which ultimately extends the life of the mechanical motor brake. Options include:

- Custom designs for specific automation requirements

- Custom system integration controls

- Ethernet connectivity

- Free-standing capability

- Custom paint colors

- Specialized perimeter guarding

- High temperature or low temperature/freezer application designs

- Horizontal infeed, carriage, and discharge conveyors

“Systems integrators will love this lift,” notes Schlegel. “It can be up-and-running in no time and the control integration is seamless. It doesn’t get much better than that!”

Based in Waukesha, Wildeck is in its 39th year as the largest manufacturer of industrial steel work platforms (mezzanines), VRCs (vertical reciprocating conveyor), and safety guarding products that are “Made in USA” and are used for the safe and efficient handling, storage, and protection of materials and personnel. For nearly four decades, the company has grown through a dedicated and experienced network of customer-service-oriented dealers and systems integrators, nationwide.

Wildeck, Inc., 405 Commerce Street, Waukesha, WI 53186, 262-549-4000, [email protected], www.wildeck.com, www.ladderindustries.com.

SMART FLOOR SIGNS

Creating smart floors is one of the fastest and easiest ways to direct behavior and create visual communication in the workplace. Floor signs promote safety and improve efficiency and are designed to help meet ANSI and OSHA standards. Visual Workplace, Inc. (Byron Center, MI) offers smart Floor Signs that enable your floors to communicate critical information about safety instructions clearly and effectively. The Floor Signs are peel and stick, easy to apply and made of durable high bond acrylic that withstand forklift and heavy foot traffic. Signs are available in three sizes: 12 in and 17 in round or 14 in x 20 in rectangles with rounded corners. Floor Signs feature a 5 mil PVC laminate that is clear, slightly textured, scratch resistant and anti-skid. The material is flexible so it conforms to curved or flat surfaces. Floor Signs are available in dozens of standard messages or custom decals are available.

The company also offers Glow Floor-Mark®, a peel and stick, glow in the dark safety product that helps building and vehicle personnel find their way in the dark, whether it’s nighttime, during a power failure, a building fire filled with smoke, a natural disaster or other emergency. It glows brightest for the first 60 minutes then fades to remain lightly visible for several hours in total darkness. Glow Floor-Mark is light green when lights are on, and emits a green/yellow glow when lights are off. The tape has a thin, durable profile designed specifically for industrial environments where forklifts and floor-scrubbers may be in use. Glow Floor-Mark is perfect for use near exits, passageways and staircases and complies with OSHA Standard 1910.22(b)(2) which states, “Permanent aisles and passageways shall be appropriately marked.” It has a unique adhesive formula that makes removal fast and easy. Simply pull it up or lightly scrape it away. It’s available in 1 in and 2 in.

Visual Workplace, Inc., 7381 Ardith Court, Byron Center, MI 49315, 616-583-9400, www.visualworkplaceinc.com.

ELIMINATES BARRIER FOR NEAR MISS REPORTING

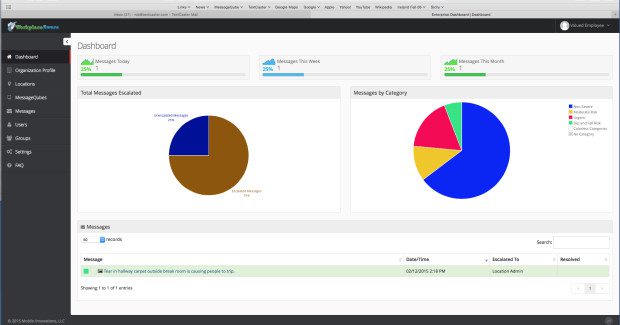

According to the U.S. Bureau of Labor Statistics, there were slightly more than three million nonfatal workplace injuries and illnesses reported in 2013. While this number is lower than previous years, the question that remains is how many near misses occurred in the workplace that were not reported and could result in a future injury or fatality. Heinrich’s widely accepted accident triangle theory states that for every major injury, there were 29 minor injuries and 300 near misses. There are many reasons for near misses not to be reported, but a new solution called WorkplaceAware from Mobile Innovations, LLC (Austin, TX) can help manufacturers improve safety by eliminating those barriers to reporting.

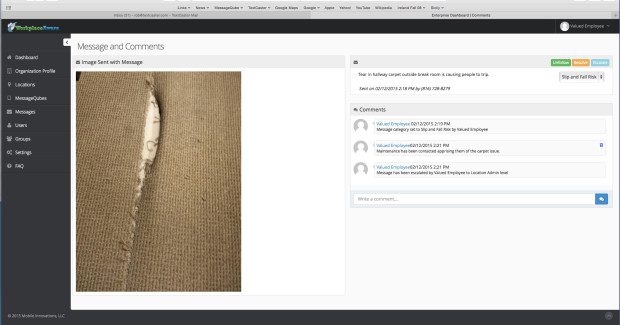

The free WorkplaceAware mobile app works with the MessageQube, a mini cellular desktop printer that receives text and photo messages from any cellular phone. Using the mobile app, employees can photograph near misses, type a description of the incident and quickly send it to their company or supervisor’s MessageQube. Simple text messages can be sent using the text message feature on any mobile phone. Once a report prints on the MessageQube, it is also posted to the employer’s online Enterprise Dashboard where management can view and manage reports, including documenting corrective action taken and escalating reports to higher authorities. Photographs and more detailed reports up to 600 characters in length are sent using the WorkplaceAware app compatible with Apple and Android operating systems.

Using WorkplaceAware, safety managers are instantly alerted to near miss and safety hazard reports as they print in real-time from the MessageQube. A green light flashes each time a new report prints making managers aware that a report has been submitted. And, the system can be configured to also notify managers via email when reports are filed. This eliminates many of the reporting barriers some shops must overcome to make workplaces safer. There are many reasons employees choose not to report a near miss incident, including fear of retribution, a desire to avoid red-tape or to avoid interrupting pace of work. By using WorkplaceAware, employees can report incidents from the field without having to fill out pages of paperwork or holding up the work day. And if they choose, reports can be submitted anonymously.