How Welding Positioners Are Helping to Save Venice

Silvestrini welding positioners are being used to fabricate massive weldments and hinges in an ingenious flood-defense barrier intended to protect the city.

Posted: May 12, 2015

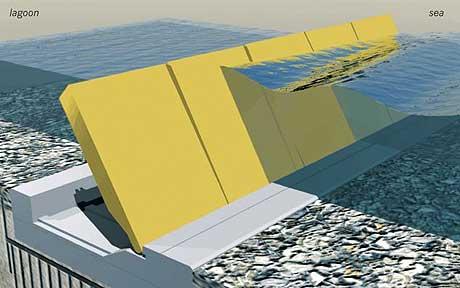

Welding positioners from Silvestrini NA (Bologna, Italy) are playing a small but important role in an ambitious flood-defense project intended to protect Venice, Italy, from the damaging floods that have plagued it for centuries. The MOSE project, whose name is an allusion to the Biblical figure Moses (or “Mosè” in Italian), is an ingenious barrier system that will protect Venice from rising sea levels.

MOSE is comprised of rows of massive gates located at the major inlets from the Adriatic Sea. The gates, which range in length from 18 m to 29 m, are anchored to the sea floor and use giant hinges to raise and lower. When not in use, the gates are flooded with water and disappear beneath the water’s surface. When flooding is predicted, the water is released by means of compressed air, causing the gates to rise up and form a temporary flood barrier. The €7 billion project was begun in 2003 and is roughly 80 percent complete.

Silvestrini welding positioners are being used to fabricate the massive weldments and hinges that allow MOSE to operate. As shown in Figure 1, an SA 500 S positioner is used to tilt and rotate a 42 ton MOSE component. The SA 500 S is 18 ft long and weighs slightly more than the weldments it manipulates. The machine’s turntable surface is 9 ft diameter and is hydraulically tiltable up to 105 deg. The SA 500 S offers variable-speed rotation in either direction, allowing welders to position and manipulate the most challenging workpieces.

Based in Northern Italy, Silvestrini is a division of Align Production Systems (Decatur, IL) and has been making welding positioners, pipe-turning rollers and other industrial positioning equipment for over 50 years. In partnership with Align, Silvestrini now offers its entire machine lineup to North American manufacturers and metal fabricators.

Align Production Systems provides standard and custom material-handling / manufacturing-automation solutions, including Airfloat air-film equipment, Safebilt ergonomic positioners and Axial industrial turntables.

www.alignproductionsystems.com