Vermont Custom Gage Installs Heat Treating System

The system from Lucifer Furnaces uses an air recirculating oven, salt bath pot furnace and quench tank to produce steel components for their gages.

Posted: April 20, 2015

Vermont Custom Gage LLC (Swanton, VT), a subsidiary of Vermont Precision Tools Inc. (Swanton VT), manufactures a wide range of fixed limit gages, including both threaded and cylindrical, with tolerances ranging from .00020 in to .00002 in. The company selected Lucifer Furnaces Inc. (Warrington, PA) to create a heat treating manufacturing capability for their shop that includes the addition of an air recirculating oven, a salt bath pot furnace and a quench tank that will be used in the production of small steel component parts of their measuring (gage) equipment.

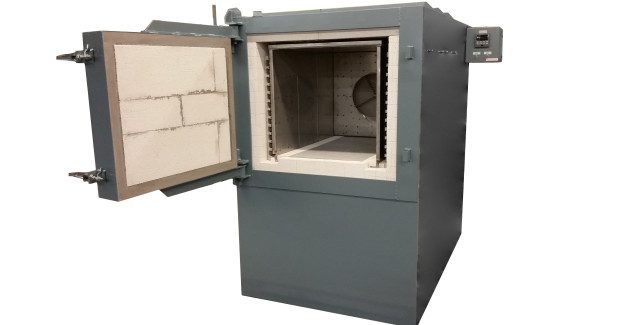

The oven, a 4000 series Model 48-R36 with working dimensions of 24 in H x 24 in W x 36 in L, heats to 800 deg F and will be used for tempering. Insulated with 6.5 in multi-layered lightweight firebrick and block insulation with a roof lined with ceramic fiber modules, the oven features a stainless steel liner that isolates the workload from the heating elements and directs airflow in a horizontal pattern. A high CFM fan assembly mounted through the oven rear wall circulates air over heating elements and back through the work chamber.

The horizontal swing door is mounted with heavy duty hinges, 6 in of insulation and two cam latches for a secure seal. After pre-heating, parts will be loaded into the Model 2055-1624 salt pot furnace and then oil quenched in a QT-2020 quench tank that is complete with air mixer, heater and soak timer. Next, the tools will be loaded into the 48-R36 oven and held at a constant temperature over a period of time to stabilize the structure of the steel.