Maintenance Showcase One

Our first review of some of the latest coolants, lubricants and metalworking fluids used in machining and fabrication operations.

Posted: April 9, 2015

VEGETABLE-DERIVED METALWORKING LUBRICANT FOR HIGHEST POSSIBLE LUBRICITY IN A WATER-BASED FLUID

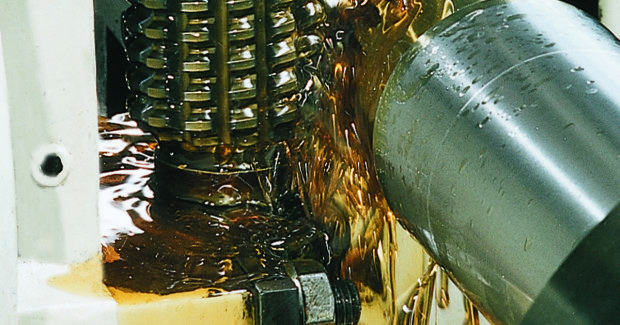

QualiChem, Inc. (Salem, VA), a rapidly growing manufacturer of metalworking fluids, has introduced EQO-PURE 452, a new vegetable-based water-soluble lubricant for severe hardened steel and stainless steel machining applications. EQO-PURE 452 is a heavy-duty vegetable-derived micro-emulsion fluid with extreme pressure additives formulated to improve tool life and part quality while eliminating foaming and staining. EQO-PURE 452 is designed for use in many applications that previously used straight oil, including boring, deep-hole drilling, gun drilling, reaming, roll forming, tapping and threading.

“This new synthesized vegetable-based lubricant is the highest performing water-based metalworking fluid on the market,” said Mike Forest, QualiChem director of metalworking. “It offers the performance of a vegetable oil without the heavy residues and emulsion instability found in other products. EQO-PURE 452 forms a stable emulsion and runs exceptionally clean, offering unmatched tool life and long service life. It’s proven to give unsurpassed machining performance while maintaining hydrolytic stability.”

QualiChem’s metalworking fluids are available through a worldwide network of more than 50 distributors. The company offers a broad selection of fluids for all types of metalworking applications. QualiChem provides extensive technical support for customers in selecting the right product to solve specific metalworking challenges. QualiChem also offers customized laboratory support services for trend analysis and troubleshooting. In other applications, BTM Corporation (Marysville, MI), a manufacturer of clinch joining systems, automation components and contract machine work, has reported substantial savings in coolant usage and waste removal costs after switching its aluminum and steel machining operations to run on QualiChem XTREME CUT 251C semi-synthetic metalworking fluid. The company has over 45 years of experience in manufacturing clamps, grippers, locators, end arm effectors, stand-alone machines and fully automated assembly systems in its ISO 9001:2008 and AS9100 Rev. B:2004 certified facilities.

Michigan Petroleum Technologies (Port Huron, MI), the QualiChem distributor in lower Michigan since 2008, oversaw the six-month trials in which BTM compared XTREME CUT 251C against the fluids it had been using. “The results of the trials on four machines spoke for themselves,” said Richard Seim, the executive vice president of Michigan Petroleum Technologies. “Coolant usage and waste removal costs were down 50 percent, and machine operators reported total elimination of noxious odors. Altogether, the total documented hard savings resulting from reduced coolant usage and waste removal costs added up to more than $47,000 in 2013.”

Dave Lamb, the BTM manufacturing manager, said, “We have an intensive coolant maintenance program and Michigan Petroleum stated that we should be able to lower consumption and the maintenance cost using XTREME CUT 251C. We tested several coolants and found that they were correct. We lowered our coolant consumption, maintenance cost, and waste coolant disposal cost using the semi-synthetic metalworking fluid.”

“I like the cleanliness, clarity and machinability of the XTREME CUT 251C,” added Tony Weber, the BTM milling supervisor. “There is minimal maintenance and operator acceptance has been excellent.” Dick Kleinknecht, the lathe supervisor at BTM, noted, “I’ve experienced excellent results with this semi-synthetic metalworking fluid. The product does not have an undesirable odor and is very easy to maintain.”

QualiChem, Inc., PO Box 926, Salem, VA 24153, 540-375-6700, Fax: 540-375-3880, www.qualichem.com.

MACHINING FLUIDS INCREASE EFFICIENCY FOR AEROSPACE, HEAVY EQUIPMENT JOBS

CYCLO COOL® 900 series synthetic metal machining fluids from 5ME (Cincinnati, OH) utilize a unique, near-neutral pH formula developed to meet heavy-duty, high-heat machining requirements at a lower cost than semi-synthetics and soluble oils. The additive-free, low-foaming fluids are specially formulated for machining titanium, Inconel®, beryllium copper, hardened steels, stainless steels, and other exotic alloys.

The cationic-based synthetic coolants contain specialized boundary lubricants that penetrate the cut zone heat barrier, even at lower fluid pressures (300 psi to 400 psi), to absorb heat from the tool and the part, minimizing tool-tip work hardening and premature wear. Free of biocides/fungicides and aggressive pH adjusters, they provide increased sump life and environmental friendliness when replacing high-maintenance, chlorinated, semi-synthetics and soluble oils in all metal removal operations. “These high-performance, low-cost traits are driving efficiency improvements in the aerospace and heavy equipment industries,” said Pete Tecos, the executive vice president of marketing and product strategy for 5ME.

CYCLO COOL 900 series fluids are designed for high-pressure, low foaming, through-tool delivery systems at 2000 psi, as well as flood coolant for chip flushing. The lubrication package in CYCLO COOL 900 varies to cover a wide range of applications from light-duty, high-speed (10,000 rpm to 15,000 rpm) aluminum milling to heavy-duty drilling and tapping of hardened steel and hard-to-machine metals. The three formulations, CYCLO COOL 900, 910, and 920 are engineered to match the intensity of the application.

For example, one facility-wide, multimillion-dollar turnkey project consisting of onsite CNC programming, application support, fixturing concepts, and tooling packages for machining large steel frames for above ground mining equipment involved the implementation of CYCLO COOL 920 throughout the facility. “The most critical application was a proprietary, specialized tapping process to lock bolts into a massive steel frame,” said Tecos. “This tapping process is critical to efficient production and, if not completed correctly, the entire frame must be scrapped.”

CYCLO COOL 920 not only met and exceeded the tight-finish tapping requirement, but it is also credited with increasing tap life to 1000 hits per tap, compared to the same process using a premium, heavy-duty soluble oil. CYCLO COOL 920 also met the plant’s corporate health and safety requirements, which include minimal-to-zero VOC levels, recyclability, and elimination of questionable raw materials and aggressive biocides/sump additives. “The near neutral pH synthetic formulation provides a clean, oil-free work area and is extremely operator and machine friendly,” added Tecos.

5ME, 4270 Ivy Pointe Boulevard, Suite 100, Cincinnati, OH 45245, 586-202-3285, [email protected], www.5me.com.

FLUIDS ADDRESS SPECIFIC METALWORKING DEMANDS

CIMCOOL® Fluid Technology (Cincinnati, OH) specializes in fluids for machining and grinding, stamping, drawing and forming, cleaners, and corrosion inhibitors, as well as specialty lubricants and fluid management equipment. For shops that specialize in gear grinding and/or milling, there is MILPRO® 740ACF, a clear, yellow metalworking oil designed for use in horizontal broaching of high temperature alloy aircraft engine parts. This chlorine free oil offers excellent water rejection, oxidative stability, rust protection, and cooling capability for a straight oil.

MILPRO® 500 is a metalworking oil blended from naphthenic base stocks and is recommended for a wide range of light to medium-duty applications such as general-purpose thread grinding, tapping, gear hobbing, gear shaving, milling, and turning. It offers a balanced blend of sulfur, chlorine, and fat that produces better finishes and longer tool life than most competitive oils. MILPRO 500 is low misting in most applications.

MILPRO® 840CF is a general purpose oil recommended for machining and grinding operations. Recommended for gun drilling, tapping, broaching, and grinding, MILPRO 840CF contains a lubrication package comprised of both a physical lubrication component and extreme pressure additives. It contains stable lubricity additives with very low depletion rates and high temperature stability. This light viscosity fluid offers cooling capability approaching water as well as provides excellent rust protection.

CIMPERIAL® 20-8SX is a premium soluble oil developed for use on carbon steels, high speed steel, cast steels, alloy steels, tool steel, stainless steel, titanium, cast iron, and most aluminum alloys. It is designed for heavy-duty operations and contains a unique blend of sulfurized and chlorinated Extreme Pressure (EP) lubricant additives to perform a wide variety of machining and grinding applications, including creep feed grinding. This low foaming product also offers very good biological protection thus providing extended sump life. While providing higher productivity and improved cleanliness compared to straight oils, it also avoids the housekeeping problems and fire hazards of straight oils. The product line’s 1072 series of fluids are designed for heavy-duty machining and grinding on both ferrous and non-ferrous metals and tested in the most challenging applications. CIMPERIAL® 1072C is a chlorinated soluble oil recommended for machining and grinding operations that offers good mix stability in high harness, high sulfate and high chloride water conditions.

CIMPERIAL® 1072D is a soluble oil recommended for machining and grinding operations on mild steels, stainless steels, hardened steels, exotics and most aluminum alloys. CIMPERIAL® 1072-HFP with FACT is a premium soluble oil recommended for a wide variety of heavy-duty machining operations including turning, drilling, tapping, reaming, gear cutting and broaching. The CIMPERIAL 1072-HFP was developed for use in high fluid pressure applications.

CIMPERIAL metalworking fluids are always “machine friendly” and engineered to save money on storage, handling, mixing, charging, make-up and maintenance costs. Specialty formulations contain extreme pressure additives providing for enhanced machining and grinding performance capabilities in the most difficult applications. CIMTECH® synthetic products improve both machining and grinding applications without using mineral oil. The CIMTECH family of products provides superior results on ferrous and non-ferrous metals in both heavy- and light-duty grinding and machining operations, and is formulated to reject tramp oil while providing a clean, low foaming, synthetic metalworking fluid that enhances machine performance and product quality.

CIMSTAR® products include a broad range of general machining and grinding fluids recommended for ferrous and many non-ferrous metals in general purpose and medium- to heavy-duty operations. CIMSTAR fluids typically contain a low to moderate amount of mineral oil and are especially useful in applications that require long fluid life and cleanliness. CIMFREE® botanical fluids are formulated with renewable resources that increase productivity and leave a smaller footprint behind. CIMVANTAGE® is an economical product line developed exclusively for light-duty applications. HFP Fluids with FACT (foam arrest control technology) provide superior foam control through the combination of product design, the selection of raw materials, and innovative antifoam technology. CIMMILL® fluids are all-new for tube and pipe processors, and are designed with the technical know-how to deliver more productive up-time and cleaner operations.

MILFORM® and MILDRAW® products include a wide range of proven stamping and drawing fluids offering lubricity, superior cooling and excellent corrosion control while making part cleaning easy and efficient. MILFORM and MILDRAW water-soluble products are available as synthetics, soluble oils and straight oils and are appropriate for both ferrous and nonferrous metals in applications ranging from light-duty stamping to heavy-duty drawing. QUANTALUBE® water-soluble fluids, which contain a patented “super-lubricant” to bridge the gap in physical lubricity between straight oils and water-based product, transform grinding and machining lubricity. This line is proven to outperform conventional soluble oils and can replace straight oils and offer many metalworking process advantages, including reduced cycle time, longer wheel life, decreased machine horsepower and improved part finish.

“Z” Products from CIMCOOL provide enhanced productivity with excellent rancidity control and longer fluid life, minimizing the need for additives and reducing concentrate usage; excellent cleanliness which extends sump life; and extended tool life.

The metalworking industry can be a messy business. Shop waste, metal swarf, oil, mold, and bacteria can cause the operating fluid mix to deteriorate and, with it, equipment performance. Choosing the right product for the shop clean out depends on the nature of soil to be removed and the type of metal to be cleaned. There are product lines available in low-and high-alkaline solutions for a variety of cleaning applications, such as parts and production, machines, floors, and other general purpose manufacturing needs. These CIMCOOL® products will be beneficial for a spring clean out:

CIMGUARD® 10 is available in bulk or aerosol containers. It is a general-purpose solvent-based corrosion preventive, an organic rust inhibitor, which has water-displacing properties, and is a fingerprint neutralizer. The protective coating is thin, transparent, colorless, and slightly oily. It can be used with steel, cast iron, copper, zinc, and aluminum.

CIMCLEAN® 30 is a general-purpose machine cleaner, which can be used on individual machine tanks and central systems. CIMCLEAN 30 is recommended for cleaning individual machine and central system reservoirs, metalworking fluid lines, premix tanks, machines, and parts. It effectively removes bio-films, dirt, grit, chip-deposits, insoluble soaps, and oils from central systems and individual machine sumps. CIMCLEAN 30 contains corrosion inhibitors to protect machines and parts from rusting during the cleaning process. It is intended for use in systems working ferrous metals. CIMCLEAN 30 can also be used for general-purpose floor cleaning. It can be used in power washers, steam cleaners, and automated floor scrubbers. It can be used in 3 ways: as a cleaner, with used fluid during shutdown, and with used fluid during production.

CIMCLEAN 40 contains corrosion inhibitors to protect machines and parts from rusting during the cleaning process. It is intended for use in systems working non-ferrous metals. It can be used in 3 ways: as a cleaner, with used fluid during shutdown, and with used fluid during production. In a continuing effort to provide the best and most cost effective options in the market, the Quick Start Trial Kit* includes everything needed to clean out a machine sump and prepare it for new fluid, providing a simple and easy switch to CIMCOOL. To request your Quick Start Trial Kit*, visit http://www.cimcool.com/starter-kit-request/ to complete the online form.

CIMCOOL Fluid Technology, 3000 Disney Ave, Cincinnati, OH 45209, 513-458-8100, Fax: 513-458-8298, www.cimcool.com.