High Water Marks

A review of some of the latest advances in waterjet cutting technology and related accessories that are now on the market.

Posted: April 28, 2015

The Vision T5 control and Columbus software, in combination with m3 plasma and 90,000 psi waterjet, work together seamlessly to provide the highest cut quality on all contours with fully automated process control from part concept to completion. This fully integrated process control in conjunction with the patented process combination makes Hydrocut LX the ultimate tool for maximum production and precision cutting.

ESAB Welding & Cutting Products, PO Box 100545, 411 South Ebenezer Road, Florence, SC 29501, 888-372-2288, www.esab-cutting.com.

HIGH-END WATERJET CUTTING SYSTEM

Semyx, LLC (Dalton, GA) offers the newly redesigned Phantom® Series waterjet cutting machine that has a precision ground body containing double rails on each side to increase durability and precision. This built to last waterjet system is driven by linear motors and features a stainless steel waterjet tank, a separate custom tank application that provides flexibility for waterjet transportation with front rollers that allow for protection for easy loading and unloading of materials. The updated Phantom waterjet cutting system uses a high ridged gantry with high pressure tubing enclosed in a special cable track. This machine comes in standard 324 and 424 tables with all of the bells and whistles and, according to the company, will still last three times longer than any other machine on the market.

This high-end water jet cutting system is driven by Yaskawa linear servomotors that improve the reliability, speed, and accuracy of performance. They can reach speeds as high as 5 mps (196 ips) and reach an astonishing 206 s of maximum acceleration. The linear servomotors are extremely energy efficient and the effects of the motor’s heat being transferred to the other areas of the machine are minimized. The main advantage of using linear servomotor technology in the waterjet industry is to have zero backlash with no mechanical engagement and zero friction from the energy transaction.

The special X- and XX-axis stainless steel static covers provide maximum protection over the lifetime of the component and easy access for maintenance purposes. The improved heavy-duty Separate Stainless Steel Waterjet Tank distributes weight evenly across the tank by using newly designed slats that have a 3X longer lifetime for better gripping of material, much better support, and reduced risk of parts falling to the tank bottom. The durable, abrasive-resistant front rollers enable bearings to last longer and assist with loading and unloading of material onto the machine.

Semyx, LLC, 1010 Abutment Road, Dalton, GA 30721, 706-529-0123, Fax: 706-529-0124, [email protected], www.semyx.com.

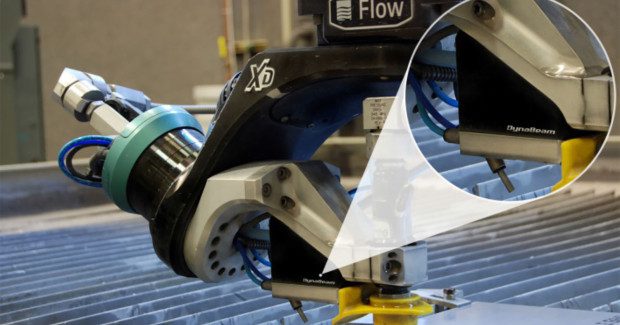

HIGH ACCURACY LASER HEIGHT SENSING FOR MORE PRECISE PARTS

Flow International Corporation (Kent, WA), a leading developer and manufacturer of industrial waterjet machines for cutting and cleaning applications, introduces the only non-contact material height sensing solution available in the industry, the DynaBeam™ Laser Sensing System. Exclusively from Flow, the DynaBeam provides superior accuracy to traditional height monitoring methods.

Laser measuring is highly accurate without requiring physical contact with a material. The DynaBeam laser height sensing technology maps the natural state of materials, reducing the need for manual adjustment throughout cutting. Operators can choose between setting the standoff height between the waterjet nozzle and the workpiece before every pierce, or pre-mapping an entire workpiece quickly and easily. Used in combination with both Dynamic Waterjet® and Dynamic Waterjet XD for 2D and 3D bevel cutting the system ensures faster, more accurate waterjet cutting. Nozzle offset height can be set to an accuracy of ±0.1mm (0.004 in) very quickly. This fast, accurate, non-contact method results in no scratches to the material. The laser ensures waterjet cutting to high precision; necessary when producing close tolerance, multi-axis parts. Operators can quickly and easily cut precise parts, even when bevel cutting.

In related news, Flow and TheSize Surfaces SL (Almassora, Spain), a manufacturer of Neolith surfaces for both indoor or outdoor use, have announced that Flow waterjet technology is the ideal cutting method of Neolith, a tough sintered surface which requires powerful, versatile methods for cutting and processing. The product is 100 percent natural, composed of raw materials – clays, feldspar, silica and natural mineral oxides – and is recyclable. Neolith has near-zero porosity, making it hygienic, stain resistant, easy to clean and impervious to chemicals. It is also wear, scratch, heat resistant and its colors, because they are all-natural, do not vary when exposed to UV rays. Because it is lightweight and easy to install, Neolith is suitable for virtually every indoor and outdoor home surface. It is often used for countertops, as well as flooring, cladding and facades.

While Neolith can be fabricated using a variety of different methods, these waterjet systems offer the unique advantage of maneuverability by providing an easy way to create sink holes, faucet holes, and even ornate details. This waterjet technology makes it is possible to easily cut countertop and detailed design elements at the same time. “The delicate precision of their easy-to-handle waterjet machinery ensure that our fabricators have a positive experience with the product,” says Daniel Sanchez, a sales manager for TheSize.

Flow International Corporation, 23500 64th Avenue South, Kent, WA 98032, 253-850-3500, Fax: 253-813-9377, [email protected], www.flowcorp.com.

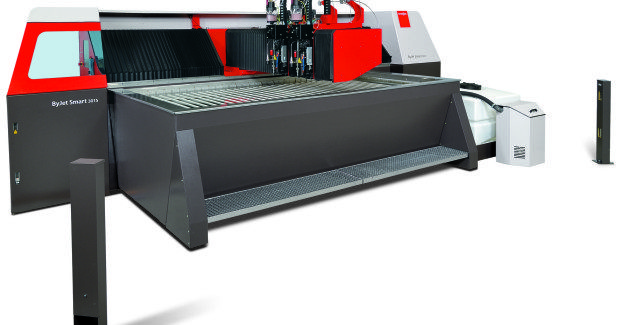

ADD MANUFACTURING CAPABILITY AND LOWER COST PER PART

The ByJet Smart from Bystronic Inc. (Elgin, IL) adds manufacturing capability to a shop’s already operating laser cutting equipment, increasing their ability to process any material without compromise. It’s also about a lower cost per part – on thicker parts a dual head ByJet Smart can produce the part for less overall cost because the capital investment is much lower and the dual heads are competitive with laser part throughputs. The high efficiency pump operates extremely reliable so that the service intervals are longer than average. High precision cutting heads combined with abrasive metering and constant automatic nozzle height sensing delivers unmatched part precision and consumable efficiencies.

https://youtu.be/upEzxAVYVZs

The ByJet Smart is equipped with numerous high-end components, including the innovative cutting bridge fitted with a linear motor and the precision manufactured machine frame constructed of heavily-damping composite material. The result of this smart combination of a proven concept and innovative technology is a durable machine with an outstanding cutting performance. The ByJet Smart high performance waterjet cutting system proves power and quality are not a question of price. The customer benefits from a low purchase price, reduced operating costs, and a lower cost per part!

Bystronic Inc., 200 Airport Road, Elgin, IL 60123, 847-214-0300, Fax: 847-214-0299, [email protected], www.bystronicusa.com.