Filler Metals

A snapshot of some of the newest filler metals used in welding applications.

Posted: April 29, 2015

STICK ELECTRODE RESISTS MOISTURE IN HUMID CONDITIONS

The Millennium Arc™ 7018 is a mild-steel, low-hydrogen stick welding consumable from The Lincoln Electric Company (Cleveland, OH) that resists moisture in humid conditions, offering 50 percent less moisture pickup than competing shielded-metal-arc-welding consumables. The Millennium Arc 7018 is designed for various applications, including mild steel, power generation, petrochemical, pressure vessels and pressure piping and is ideal for all welding positions, except vertical down. It has no intentional addition of zinc in its composition, which means significantly less zinc in the welding fume – and a safer environment, overall. Other key features include:

- Clear weld puddle without slag interference

- Flat bead profile

- Effortless slag removal

To request a copy of Millennium Arc 7018 literature, obtain bulletin C2.10.33.

The Lincoln Electric Company, 22801 Saint Clair Avenue, Cleveland, OH 44117-1199, 888-355-3212, www.lincolnelectric.com.

ADVANCED WELDING FILLER METALS

ESAB Welding & Cutting Products (Florence, SC) offers its extensive line of welding filler metals, including the new Coreweld C6 LF metal-cored wire and two new welding wires for the Dual Shield II Series of flux-cored welding consumables. Coreweld C6 LF is a new low manganese emission, high efficiency metal-cored welding wire developed in response to new EPA regulations and guidelines from ACGIH (American Conference of Government Industrial Hygienists) for manganese exposure limits. Coreweld C6 LF has more than 50 percent lower manganese content and is designed to provide excellent operating qualities while significantly reducing the manganese levels in the welding fumes when compared to standard metal-cored electrodes of the same classification.

ESAB’s optimized formulation aids users in their efforts to reduce exposure to manganese in the welding environment while providing good mechanical properties and low weld metal diffusible hydrogen levels. Coreweld C6 LF offers the same enhanced features of the standard Coreweld C6 with welder-friendly operating characteristics, including consistent arc stability, very low spatter, good bead shape and minimal clean-up in an easy-to-use wire. Its low diffusible hydrogen level helps avoid hydrogen-induced cold cracking in the welding of high strength steel.

ESAB has added two new wires to its Dual Shield II Series of flux-cored welding consumables. The Dual Shield line offers the broadest variety of mild steel and low-alloy flux-cored wires available in the world. Dual Shield wires offer excellent welding performance in all positions with high deposition rates and efficiencies, dramatically reducing weld time and increasing productivity. Dual Shield wires are also easy to use and produce a weld bead with almost no ripple and very little spatter. Dual Shield II 4130 SR is an all-position flux-cored wire for welding low-alloy, high-strength steels such as 4130. This welding wire is ideal for offshore oil and gas topsides and platforms requiring high corrosion resistance with stress-relieved high strength and low temperature impact toughness properties. ESAB’s new Dual Shield II consumable offers mechanical properties in the as-welded and after PWHT conditions and meets ANSI/NACE MR0175/ISO 15156-1.

Dual Shield II 70-Ni1 H4 is designed for use under 75 percent Ar/25 percent CO2 gas protection. This flux-cored wire provides excellent low temperature toughness in both as-welded or stress-relieved conditions. Dual Shield II 70-Ni1 H4 produces low diffusible hydrogen levels – lower than 4 ml/100 g – over a wide range of welding parameters. The smooth arc, fast-freezing slag, low spatter levels and easy slag release make this an ideal wire for the welding of steel plate in all positions. With nickel content below 1 percent and Brinell hardness less than 200, this welding wire meets the requirements for applications where resistance to stress-corrosion cracking is required. It is best suited for the fabrication of storage vessels that need to be stress relieved to minimize the occurrence of stress corrosion cracking (SCC).

ESAB Welding & Cutting Products, PO Box 100545, 411 South Ebenezer Road, Florence, SC 29501, 717-630-3439, [email protected], www.esabna.com.

WELDING WIRE REDUCES WIRE SHAVINGS FOR MORE COST-EFFICIENT WELDING

AlcoTec® Wire Corporation (Traverse City, MI), an ESAB company, offers its patent-pending 5XXX Series NT aluminum welding wire that applies the latest innovation in wire manufacturing technology to significantly reduce or virtually eliminate wire shavings. NT technology produces a clean, high-quality aluminum welding wire that will not clog torch liners and offers better feedability for more cost-efficient welding. Wire shavings are generated as a result of equipment and wire characteristics. Microfines or scales attach themselves to the walls of the torch liner causing surface abrasion of the wire during manufacturing, which produces wire shavings. Abrasions from wire-to-wire touching during spooling operations that flake off while welding also contribute to shavings. Shavings are usually collected in the liner, but can also accumulate on drive rolls and contact tips. Clogged liners often result in increased tip and liner replacement, downtime, and re-work.

AlcoTec NT wire process uses patent-pending manufacturing technology to eliminate the microfines and surface abrasion generated during wire drawing. This technology minimizes or eliminates the shaving problem, thus greatly improving wire feedability and arc stability. NT wire technology produces a clean, high quality aluminum welding wire that will not clog torch liners. As a result, there is less wear and tear on contact tips and liners, which don’t have to be replaced as often or as a result of wire shaving. In addition to reduced contact tip and liner replacement costs, NT wire also reduces downtime, ultimately extending the life of the welding torch.

AlcoTec is the world’s largest single-source manufacturer of premium aluminum welding wire, offering a wide range of aluminum wire and rods for GMAW (MIG), GTAW (TIG), brazing and metallizing. The company controls every aspect of the manufacturing process from production, to testing, to packaging with no outsourcing.

AlcoTec Wire Corporation, 2750 Aero-Park Drive, Traverse City, MI 49686, 231-941-4111, Fax: 231-941-9154, [email protected], www.alcotec.com.

ALL-POSITION STAINLESS STEEL WIRE FOR CRYOGENIC WELDING APPLICATIONS

Stoody® (Bowling Green, KY), an ESAB brand, offers the stainless steel joining product, Brilliant 308L T-1 CRYO, a gas-shielded flux cored wire that has been specifically designed for all position welding in cryogenic applications with either 100 CO2 or Argon/CO2 gas mixtures. Joining the Stoody family of all position stainless steel wire electrodes, CRYO can be used to join AISI 304 in extreme cold applications, such as construction and maintenance of liquid hydrogen and LNG transfer lines and storage vessels. Initially available in a 0.045 in (1.2 mm) diameter wire, CRYO exhibits a spray like arc transfer, easy slag removal and can be welded within a wide range of parameters. Classifications include AWS A5.22/A5.22M:2012 E308LT1-1J/-4J and ASME II SFA5.22 E308LT1-1J/-4J.

Stoody Company, 5557 Nashville Road, Bowling Green, KY 42101, 270-495-3976, [email protected], www.victortechnologies.com.

LOW MANGANESE FILLER METAL FAMILY INCLUDES METAL-CORED WIRE

To help shops create a safe, comfortable and compliant welding environment, Hobart Brothers Company (Troy, OH) has expanded its FabCOR® Element™ family of low manganese wires to include a new metal-cored wire — the FabCOR Element 70C6. Results of extensive testing show the FabCOR Element 70C6 wire — like the six available FabCOR Element gas-shielded flux-cored wires — features among the lowest manganese emissions of similarly classified American Welding Society (AWS) A5.18 E70C-6 wires in the marketplace. These low manganese levels assist fabricators in their efforts to conform to increasingly strict environmental regulations.

The new FabCOR Element 70C6 wire offers additional benefits associated with other Hobart metal-cored wires, including increased deposition rates (compared to solid wires) that result in faster travel speeds and greater productivity. In addition, this wire has been specifically formulated to simplify silicon removal, again increasing productivity by reducing the need for time-consuming post-weld cleanup. The FabCOR Element 70C6 wire also offers balanced arc characteristics, providing a smooth, penetrating transfer and a consistent, high-quality weld. This versatile wire provides exceptionally low diffusible hydrogen levels to help mitigate the risk for hydrogen-induced cracking. When paired with a 75/25 argon and carbon dioxide shielding gas mixture, the FabCOR 70C6 offers 2.0 ml of diffusible hydrogen per 100 g of weldment. Operating with a 90/10 shielding gas blend yields ≤ 4.0 ml of hydrogen per 100 g of weldment.

The FabCOR 70C6 wire is suitable for single- or- multi-pass welding on heavy equipment, shipbuilding, general fabrication and railcar applications, and Hobart will offer it in industry-standard diameters of 0.045 in, 0.052 in and 1/16 in on 33 lb spools or 60 lb coils.

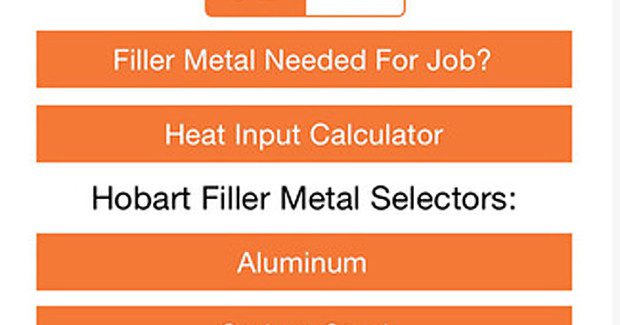

In related news, the new Hobart Filler Metal Selector and Calculator app is now available for download for iPhone and iPad via the App Store®. This free app is a quick reference tool designed to help users determine how much filler metal is needed for a job, and it provides filler metal recommendations for welding various materials. It also includes a heat input calculator and a hardfacing product cross reference function. To determine the volume of filler metal required for a job via the app, users simply select a weld joint type and enter the dimensions of the weld size using either Standard (SAE) or metric units. The app also requests the user to input the total weld length, material and transfer modes, resulting in a calculation for the amount of filler metal in pounds or kilograms required to complete the weld. The volume calculator works for aluminum, stainless steel and carbon steel MIG and flux-cored welding applications.

The heat input calculator in the Filler Metal Selector and Calculator app allows users to input voltage, amperage and travel speed variables to determine heat input for a given application, while the filler metal selector option provides recommendations for Hobart filler metals, with a direct link to the product pages on HobartBrothers.com, based on the base metals (aluminum, stainless steel or carbon steel) that will be welded together. The filler metal results list the appropriate American Welding Society (AWS) classification for the recommended products. A hardfacing product cross reference function in the new app allows the user to determine the filler metal equivalent to competitive manufacturers’ products.

Hobart Brothers Company, 101 Trade Square East, Troy, OH 45373, 800-424-1543, Fax: 800-541-6607, [email protected], www.HobartBrothers.com.