Welding Automation

Here are some of the new automation solutions that are helping shops make their welding operations more productive and profitable.

Posted: February 27, 2015

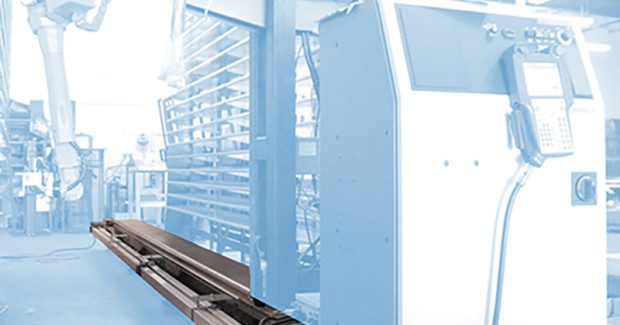

LASER WELDING MADE EASY

From simple sheet metal parts to bent profiles, the TruLaser Robot 5020 from TRUMPF Inc. (Farmington, CT) provides for easy entry into laser welding. Its innovative and modular system clamps components of different sizes and shapes so the machine can quickly begin the welding process. Several components can be joined in a single processing step depending on the size of the part. The procedure is the same regardless of whether it is conduction welding or deep penetration welding; long seams or corner connections the fabricator desires.

The TruLaser Robot 5020 is able to share a laser source in a laser network, for example, a flatbed 2D laser cutting machine. With this capability, the TruLaser Robot 5020 provides the most flexible and cost effective entry into laser welding.

Once the part is selected and the clamping unit set, a highly productive manufacturing process is the essential next step. While even the standard model of the TruLaser Robot 5020 fitted with a hand-operated turntable will enable high productivity, the optional automatic rotational turntable increases output even further since an operator can set up the next part while the laser is active. The operator is always fully protected from the laser beam and rotational unit while loading and unloading parts. The system only rotates when the internal sensor determines the area is completely clear and free of danger. Additionally, the load-bearing capacity of the rotational unit is 1,650 lb per side, allowing for several components to be welded simultaneously.

TRUMPF Inc., 111 Hyde Road, Farmington Industrial Park, Farmington, CT 06032, 860-255-6000, Fax: 860-255-6424, www.us.trumpf.com.

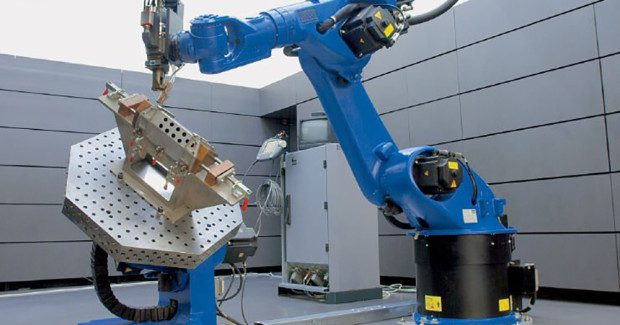

IMPROVED LASER-BASED SEAM FINDER

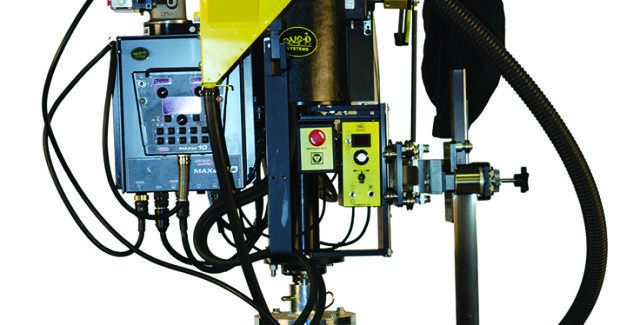

Yaskawa Motoman (Miamisburg, OH) introduces an improved AccuFast™ laser-based seam finder for their broad range of arc welding robots. AccuFast laser seam finder provides the benefits of a non-contact vision sensor at an economical price. “AccuFast enables customers to quickly and accurately locate welding seams using a non-contact laser,” says Chris Anderson, the welding product marketing manager. “Our product is faster and more accurate than traditional weld wire touch methods and blends well with all of our newest digital power source interfaces. We offer the broadest range of seam-finding and seam-tracking solutions for arc welding, which our customers use to manufacture their products with fewer defects.”

The AccuFast laser seam finder is compact, mounted in-line with the welding torch and as always, is compatible with Yaskawa Motoman’s industry-leading thru-arm torch design robots. Macro job routines make programming easy and seamless. The laser sensor is housed in an enclosure with a pneumatic shutter to protect it from the welding environment. An optional laser target aids in maintaining the sensor TCP and can adjust points if the sensor is serviced.

Yaskawa Motoman also offers the sleek, strong and fast, the new 6-axis MA1440 arc welding robot that features a 6 kg payload, up from 3 kg on the MA1400 model. The new MA1440 features a 23 percent larger wrist hole for utilities, is up to 15 percent faster, and is introduced with the new DX200 robot controller that is more energy efficient and designed for improved maintainability. The MA1440 features a new contoured arm structure that reduces interference by enlarging the close-range motion area of the robot, making it optimal for welding large workpieces and reaching over jigs. The upper arm shape also provides an improved mounting area that allows more room for the feeder. Available in floor-, wall- or ceiling-mounted configurations and ideal for high-density layouts, the space-saving MA1440 robot increases productivity due to its Sigma-5 motor control technology.

The MA1440 robot has a 1,440 mm (56.7 in) horizontal reach, 2,511 mm (98.9 in) vertical reach and ±0.08 mm (±0.003 in) repeatability. Its integrated through-the-arm torch cabling eliminates cable interference, simplifies programming and reduces cable wear. The enlarged 50 mm thru-hole can allow signal cables for sensors, higher current cables and water-cooling lines. The higher payload allows motorized torches and cameras to be mounted on the wrist for welding applications.

Also sleek, strong and fast is the new 6-axis MA2010 extended-reach arc welding robot that features a 10 kg payload, up from 3 kg on the previous MA1900 model. The new MA2010 features a 23 percent larger wrist hole for utilities, has a 6 percent longer reach, and is also introduced with the DX200 robot controller. The MA2010 also features a new contoured arm structure that reduces interference by enlarging the close-range motion area of the robot, making it optimal for welding large workpieces and reaching over jigs. Its hollow upper arm maintains the optimum bend radius of the welding torch cable, maximizing weld performance.

The T-axis can rotate the torch ±210 deg without cable interference. Available in floor-, wall- or ceiling-mounted configurations for workcell flexibility and ideal for agriculture and construction machinery parts due to its longer reach. The MA2010 robot has a 2,010 mm horizontal reach, 3,649 mm vertical reach and ±0.08 mm repeatability. Its integrated through-the-arm torch cabling eliminates cable interference, simplifies programming and reduces cable wear. The enlarged 50 mm thru-hole can allow signal cables for sensors, higher current cables and water-cooling lines. The higher payload allows motorized torches and cameras to be mounted on the wrist for welding applications.

The new Motoman® MA3120 arc welding robot features an extra-long reach arm that reduces the need for tracks. It is the longest robot arm designed for arc welding. Available in floor-, wall- or ceiling-mounted configurations and ideal for multiple robot layouts, the MA3120 has been improved over the previous MA3100 model robot with twice the payload, longer reach and improved through arm wrist design for arc welding.

The MA3120 has a 6 kg payload, 3,121 mm horizontal reach and ±0.15 mm repeatability. Its integrated through-the arm cabling eliminates cable interference, simplifies programming and reduces cable wear. It has heavier payload capacity and an increased through hole wrist diameter making it easier to integrate pull-torches or welding sensors. Welding utilities (gas hose and feeder signals) can be routed through the robot base and the wire feeder mounts to the upper arm to reduce the torch length. The MA3120 is perfectly suited for use in workcells with larger workpieces, as well as for applications that require access to parts in tight spots or those with possible interference from fixtures.

Yaskawa Motoman also offers the new compact high-speed MS165 and MS210 robots that are 20 percent faster overall than previous ES-series robots and designed to deliver unmatched performance and reliability in spot welding applications. The use of a gas spring and Sigma-5 motor technology result in a lighter weight and a reduced-profile design to allow higher robot density around a car body or a smaller workcell for Tier 1 applications.

To increase cable life, enhance safety and reduce teaching time, the servo gun cables and air and water lines are routed through the robot’s base and upper arm to the wrist. The streamlined design enables the MS165 and MS210 robots to reach into confined spaces, thus reducing cycle time and improving system productivity. The integrated spot harness technology introduced over a decade ago has proven its reliability on the successful ES-series robot line. This technology has been improved on the MS-series with an expanded wrist working range of up to 17 percent, and back-integrated control for spot guns with servo motor drives improves weld quality.

The six-axis MS165 and MS210 models feature increased payloads of 165 kg (363.8 lb) and 210 kg (463 lb) respectively. Both models have a 2,702 mm (106.4 in) reach with a repeatability of ±0.2 mm (±0.008 in). The high-speed spot and ARM (Advanced Robot Motion) control functions can provide up to 35 percent cycle time reduction and improve quality by providing consistent electrode force with optimum arm and gun motion control.

All of these robots use the DX200 controller that features patented multiple robot control technology to easily handle multiple tasks and control up to eight robots (72 axes), I/O devices and communication protocols. Its extensive I/O suite includes integral PLC and HMI pendant displays, high-speed Ethernet communication, 4,096 I/O addresses and a graphical ladder editor that can provide system level control. The DX200 has been designed to improve process capability, reduce energy usage, and improve maintainability and safety. An enhanced Functional Safety Unit (FSU) provides control reliable zone and tool position monitoring, stand still monitoring and speed limiting. This can reduce costs for safeguarding hardware and provides new capabilities such as collaborative tasks. It is compliant to ANSI/RIA R15.06-2012 and other relevant ISO and CSA safety standards.

Founded in 1989, the Motoman Robotics Division of Yaskawa America is a leading robotics company in the Americas. With over 300,000 Motoman robots installed globally, the company provides automation products and solutions for virtually every industry and robotic application, including arc welding, spot welding, material handling, material cutting, material removal and more.

Motoman Robotics Division, Yaskawa America, Inc., 100 Automation Way, Miamisburg, OH 45342, 937-847-6200, Fax: 937-847-6277, www.motoman.com.