Welding Automation

Here are some of the new automation solutions that are helping shops make their welding operations more productive and profitable.

Posted: February 27, 2015

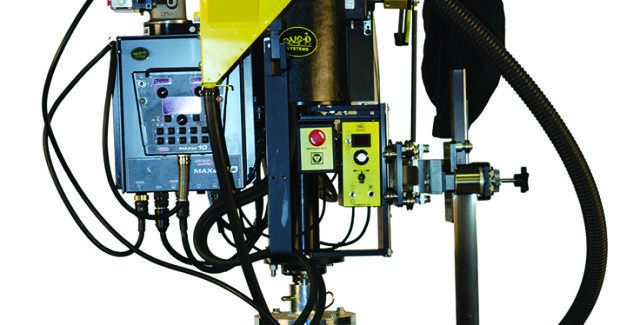

SUPERIOR ORBITAL MIG WELDING

The Lincoln Electric Company (Cleveland, OH) introduces an orbital metal inert gas (MIG) welding system that is ideal for industries where orbital welds are subject to exceptionally high standards, such as pipeline, construction or process piping. Combined with Power Wave® technology, the system redefines industry-wide parameters for quality, consistency and productivity. The system is driven by the APEX® 3000 Mechanized Controller, and it pairs with the HELIX® M85 weld head and track ring. Each component in the system has the ability to operate together, while the Power Wave advanced process welder can function independently.

The HELIX M85 weld head, as a digital system, calculates and controls travel time, weld speed and other variables, thereby alleviating complicated setup work on the front end. The track ring design allows the operator to install or remove the track in seconds. It also eliminates binding and compensates for work surface heat expansion. The gear-driven track resists wear, ensuring quality and consistency. The system also features an ergonomic, hand-held pendant with icon-based interface and full-color screen. “Quality and productivity don’t have to be difficult,” said Carlos Richmond, a product manager of mechanized automation at Arc Products, a Lincoln Electric company. “Our new system offers the kind of versatility and efficiency that’s expected for achieving superior orbital MIG welds the first time.”

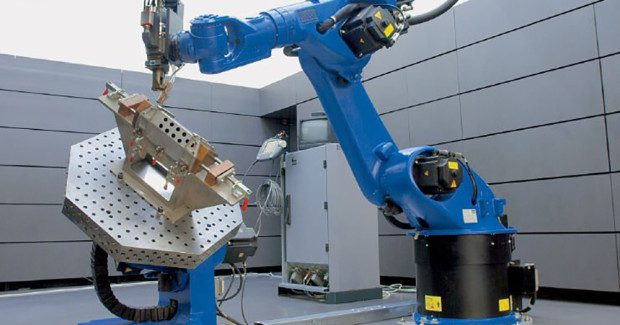

Lincoln also offers affordable robotic welding cells for shops that are first-time buyers in welding automation: the Auto-Mate™ pre-engineered robotic welding cell. These affordable cells enable the new buyers to quickly and easily implement automated welding. These cells can be delivered in two to four weeks, so buyers can make a capital equipment decision and quickly reap the benefits of automation. The Auto-Mate pre-engineered cells – Auto-Mate 5 and Auto-Mate 10 – create an easy entry point for first-time buyers and an affordable stepping stone to a more elaborate and sophisticated system further down the line.

Auto-Mate 5 is a single-zone cell suitable for welding medium-sized to larger parts. Auto-Mate 10 is a two-zone cell, but with the same footprint as the Auto-Mate 5. If your process includes smaller parts, the robot can weld on one side while the operator handles parts on the other. Both cells enable MIG and flux-cored welding processes performed by a Fanuc® Arc Mate® 0iB robot driven by a Power Wave® R350 power source. Power Wave software controls and monitors welding processes to deliver optimized welds for any steel, stainless steel or aluminum applications while simultaneously delivering production data on the operations – enhancing quality and productivity – two vital components that make the small business bigger and more competitive.

The Auto-Mate line is engineered for the first-time user of robotic systems with an affordable list price of $59,999. The setup and programming procedures are intuitive and user friendly. There is also standard, three-day training at no cost available in Cleveland, so the buyer can quickly start operations.

Lincoln also introduces a mobile application designed to provide common weld settings for SMAW, GMAW/FCAW and GTAW processes. The Weld Parameter Guide mobile application is available for Apple® iOS devices and Android™-enabled devices. Welders can use the app to find the correct welding parameters for their projects, welding process, material and thickness. Designed for welders in the shop or in the field, the Weld Parameter Guide provides convenient access to information that will help them set up their weld operations on the go, with no Internet or Wi-Fi connection required. The App’s key features include:

- Easy-to-use graphical interface, featuring icon-based menus.

- Dynamic, “smart” look-up tables – As the user enters data, each additional parameter range is narrowed based on the valid options remaining.

- S. and metric settings option.

- Typical machine settings for SMAW, GMAW/FCAW and GTAW welding processes.

- Steel and stainless steel material machines settings for SMAW.

- Aluminum, steel and stainless steel material machine settings for GMAW/FCAW and GTAW.

- Integrated Data – No need for Wi-Fi/Internet access. Great for remote locations where cell phone/Internet service is limited.

- Notes section that allows the user to add additional weld set-up information.

The Weld Parameter Guide is available at no cost to smartphone and tablet users through the Apple iTunes® App Store and the Google Play Store™. The app is compatible with Apple iOS devices (Apple iOS Version 6 and newer) and Android™-enabled devices (Android™ Version 2.2 and newer).

The company also introduces the RoboTank™ robotic tank welding system for fabricators producing tanks and vessels for the energy, automotive and heavy equipment industries. This new robotic welding system can be used to fabricate most tank designs and includes tooling used to properly present the weld joints to the robot. These systems can be configured into either a manually aligned or fully automatic seam tracking solution.

Vision tracking software can detect plate and weld joint locations and use that information to accurately place and hold various parts for welding. Offset information from one vision-equipped robot can be transferred to other robots within the cell. Laser tracking equipment can be used to assist in locating and tracking circumferential and longitudinal weld joints. RoboTank is also versatile enough to accept multiple material types. Aluminum to steel changeovers are quick when utilizing a servo-driven welding gun and Lincoln Electric’s Power Wave® R500 welding power source used in conjunction with the Advanced Module used to extend the system’s capabilities.

When developing a customized tank or vessel solution for each customer, the company provides robotic welding tank demonstrations at its facilities in Cleveland or at the customer’s site at no cost. Lincoln Electric Automation Solutions is the only robotic integrator with more than a century of welding experience and expertise. The company serves as a single source for tank welding system automation, with all development and design for each application completed in-house. This approach assumes centralized accountability for the design and eliminates the potential for miscommunication among multiple vendors. It also results in reduced lead times from purchase order to delivery, so that a customer can quickly get their system operating on site and contributing to the bottom line.

Lincoln Electric also released its newly redesigned 2015 Equipment Catalog (E1.10), which details the company’s MIG, TIG, and multi-process welding equipment, as well as plasma cutting systems, welding automation, fume control systems, training product solutions, orbital welding systems, accessories, and welding gear products. The company introduced an updated appearance for the catalog that is clean and simple, allowing users to easily navigate its contents to find the products that will best meet their welding and cutting needs.

Concurrent with the release of the printed catalog, the 2015 Lincoln Electric Equipment Catalog has also been released for use on iPads and Android devices on the company’s Lincoln Library® mobile app, available in the Apple® App Store or the Google Play™ store. These versions of the catalog offer users the ability to directly link to rich media, including videos and web pages from within the application.

Lincoln Electric is a world leader in the design, development and manufacture of arc welding products, robotic arc welding systems, plasma and oxy-fuel cutting equipment and has a leading global position in the brazing and soldering alloys market. Headquartered in Cleveland, the company has 48 manufacturing locations, including operations and joint ventures in 19 countries and a worldwide network of distributors and sales offices covering more than 160 countries.

The Lincoln Electric Company, 22801 Saint Clair Avenue, Cleveland, OH 44117-1199, 216-481-8100, Fax: 216-486-1751, www.lincolnelectric.com.