Using Adaptive Grippers as Flexible Fixturing For Robotic Welding

Using a traditional jig for every type of piece and assembly is complicated and expensive when welding small volumes or high mixes of parts. Why not use a robot with an adaptive gripper to feed a welding robot? This could replace most of the templates currently used by adapting to any part size and shape and holding them firmly while welding.

Posted: February 27, 2015

For high volume production, jigs are commonly used for fixing and positioning the part to weld on the assembly. Mixed-model production presents the challenge of dealing with each time the assembly type changes on the line, every template has to be changed and this increases the cycle time.

Why not use a robot with an adaptive gripper to feed a welding robot? The robot would have a hand which can grab any part, regardless of size or shape, position it on the assembly and hold it tight during welding. Even with a second robot and robot gripper, this solution will be more economical than buying all the required jigs and adding the time related to changeovers. Since there is no change needed to start another model on the line, changeover time is eliminated and this makes the production line more efficient. Speaking of efficiency, using robots shortens the reaction time and increases the speed of production.

http://youtu.be/iW2dyeTitcY

To determine if this was possible, different tests were conducted inside a robotic welding cell by Robotiq, Inc. (Lévis, QC), in collaboration with the Industrial Robotics and Vision Center (CRVI; Lévis, QC), to:

- Use an adaptive robotic hand to replace all templates.

- Test the consistency and precision of the system.

- Test the resistance of the system to the welding environment.

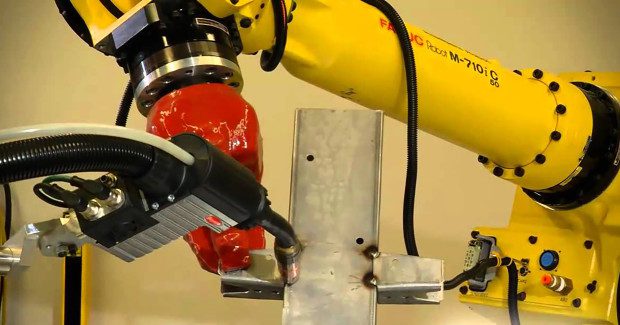

The main goal was to integrate a complete robotic welding cell by using a 3-Finger Adaptive Gripper as flexible fixturing instead of traditional jigs. Several tests were conducted involving precision and repeatability of the system. The objective was to position a piece on a structure at ± 1 mm accuracy and weld it. Since the system being used was designed for series production, it had to reproduce each step numerous times with the same accuracy. The material used included Mightex cameras with Pentax optics and Fanuc M-170iC robots which were already installed at CRVI. Those elements were chosen because they are affordable and common in the industry.

GRIPPER DURABILITY

The lifetime of the end effector was determined by a long-running test which consisted of making the gripper open and close until the hand became non-functional. The robot hand made total closure as well as partial ones. A partial closure allows the gripper to be faster at grabbing the parts since the closure is already partially done when reaching the piece. This test ran seven days a week, 24 hours a day for over six months. Regular inspections were made to determine when the grippers would need to have maintenance. With those inspections, modifications were made to the product to improve its durability.

PRECISION AND REPEATABILITY

In order to test the precision of the total system, it must be calibrated. A calibrating tool-tip was used to calibrate the hand position on the robot. Cameras were used as measurement tools and images were calibrated with a commercial calibration grid. This step is necessary because the camera needs to recognize and convert pixels in three-dimensional space to be able to locate the piece. The robot movements were also calibrated using the cameras.

For the precision and repeatability tests, two cameras were used. First, the cameras were tested. Several images of fixed objects were taken by the cameras to evaluate distances and determine their precision and repeatability. Second, a camera was aimed at the gripper while it was performing several open and closure sequences. Each time the position of the gripper was recorded. Third, the robot was tested by moving it to a preprogrammed point and then measured to get its real position by the cameras. Finally, the entire system had to be tested. Camera one was locating the part to be picked. Then the robot arm with the gripper had to move to this location and grab the part. Next, the robot had to bring the part to a specific point on a fictive assembly. The second camera had to evaluate the coordinates of the final destination.

These movements were repeated several times. The results helped to determine the precision of the entire system. Since a welding glove was being developed at this time, the same test was made with it. The desired precision was of at ± 1 mm accuracy 1 mm. The final results are the following:

| Table 1: Repeatability of each system component. Elements Repeatability (mm) | |

| Camera | 0.008 |

| Robot | 0.024 |

| Gripper (total and partial closures) | 0.065 |

| Entire system | 0.075 |

| Entire system with welding glove | 0.277 |

PROTECTIVE GLOVE

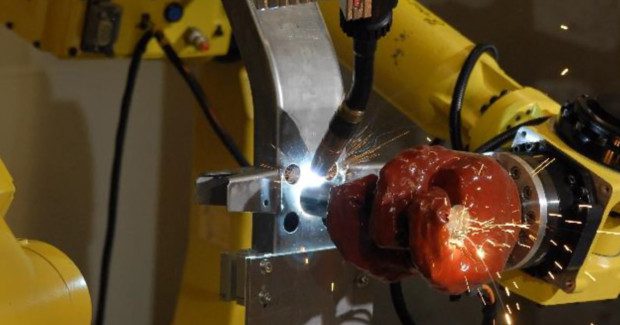

The main purpose of the flexible robotic welding cell is to replace all templates and fixtures by a flexible robot gripper for any part type. In order to further protect the robotic gripper, even though it is already made of industrial grade materials, a glove was developed to protect it from extremely high temperatures. The principal characteristics of this glove were the following:

- No welding projection should penetrate through the glove.

- No welding projection should burn the glove.

- The glove material should resist temperatures as high as the welding arc.

The end effector protector prototype is made of silicone. The tests conducted were simple. The robot gripper was holding a metallic object in its glove and some welds of various lengths were made at different distances from the glove. Then the glove was inspected to see if every characteristic mentioned above was respected. Different types of materials were also used, such as stainless steel, because it creates a lot of welding projection. By doing the same tests in this harsh environment, the glove managed to give satisfying data. Some projections did damage the glove but they were superficial. However, in other tests, the glove appeared to tear under certain conditions. So the team plans to keep on improving it in order to provide the best quality product for the application.

ROBOTIC WELDING CELL

After all the independent tests, the system was ready to work in a complete welding cell. A complete cell was installed to proceed with the main testing. In order to do the tests, a representative assembly from a client was used in the cell. First, the position of all the elements (cameras, robot with adaptive hand, welding robot) was optimized. Then, an EtherNet/IP commercial communication system was set up between the robots to insure a strong and safe link. Algorithms previously used in other tests were slightly modified. Afterwards, all the pieces and weld positions on the assembly were programmed and integrated into the cell.

The demonstration featured ten pieces, 18 spot welds and ten continuous welds. The quality of positioning exceeded expectations with a repeatability of 0.1 mm (0.3 mm with the glove).

CONCLUSION

The main goal was reached when the complete flexible robotic cell worked. The testing also increased the knowledge about using a robot gripper to help in future field support. Even if the tests were satisfying with the 3-Finger Adaptive Gripper, both of the 2-Finger Adaptive Grippers that were trialed brought new insights to the welding cell. They are mechanically simpler and more robust in a welding environment. They have the same adaptive criteria specific, have been tested and have lasted more than 10 million cycles – and were still working perfectly.

Robotiq is confident that its electric end effectors can replace most of the templates currently used in the industry. They adapt to any part size and shape and can hold them firmly during the assembly process. Other robotic hands currently on the market cannot grab a wide variety of parts or they don’t provide the industrial toughness required.

These flexible fixtures also replace the clamping and welding process with a one-step task. Moreover, the assembly can be made faster and the production cost lowered even with a second robot and a gripper. The robot will grab the piece, install it on the assembly and hold it during the welding process. This meets the challenge of small volume and high mix productions. Further research will continue to be done to improve the whole system.

Robotiq, Inc. 966 Chemin Olivier, Suite 325, Lévis, Québec, Canada, G7A 2N1, 888-762-6847, Fax: 418-800-0046, robotiq.com.