Transforming the Way Material is Cut

A review of some of the newest laser cutting systems, laser marking equipment, and related accessories and services now on the market.

Posted: February 2, 2015

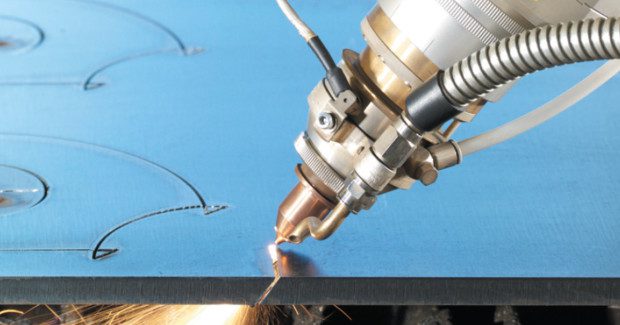

LARGE PLATE LASER CUTTING

ESAB Cutting Systems (Florence, SC), an industry leader in plasma and oxyfuel cutting, has joined forces with TRUMPF to produce the Alpharex large plate laser cutting machine. With working widths of up to 17 ft (5 m), the Alpharex has no theoretical restriction in working length. The specially designed laser resonator is mounted on the machine and moves with the machine in the longitudinal direction. In the transverse direction, the beam is delivered by flying optics to the workpiece. This design feature eliminates beam divergence along the longitudinal axis, and ensures that the laser intensity and the cut quality remain constant over the full work space.

The Alpharex laser cutting machine is fitted with a CO2 laser system supplied by TRUMPF. The TLF-turbo lasers, featuring power selections of 3.2 up to 6 kW, guarantee high precision cutting of carbon steel up to 1.0 in (25 mm) thick. The Alpharex may also be configured with a laser bevel head for cutting up to 450 bevels on parts. Specifications are as follows:

| Alpharex | 5000 | 6000 | 7000 |

| Cutting Width | 120 in (3,000 mm) | 157 in (4,000 mm) | 198 in (5,000 mm) |

| Cutting Length | No Theoretical Limit (1 meter increments) | ||

| Parking Length | 177 in (4,500 mm) | ||

| Max. Positioning Speed | 1,000 ipm (25,400 mm/min) | ||

Please note that specifications are subject to change without notice. Please contact ESAB for the most current specifications, numerical control, and available equipment.

The laser process is fully controlled and automated through Vision CNC. All laser parameters, such as power, frequency, piercing routines, gas pressures, and cutting height, are set automatically by the CNC. The Vision CNC also controls the adaptive optics which provides autofocus and also ensures consistent beam quality. Other features on the Alpharex include:

- Large working area increases plate utilization when nesting and cutting large parts.

- Class 1 Laser protection with the optional PRO-LAS enclosure.

- Optional Laser Contour Beveling up to 450 facilitates welding preparation.

- Production cutting to 1 in carbon steel, 5/8 in stainless steel, ½ in aluminum.

- Cutting and marking with the same laser tool.

- Video camera monitoring of the process at the operator’s console.

- Complete process control and automation through Vision CNC.

- Oversized AC Drives for high dynamic response and excellent positioning accuracy.

- CNC controlled auto-focus using adaptive optics for highest reliability.

- Pierce detect and cut loss detection.

- Safety light barriers front and rear.

ESAB Cutting Systems, 411 S. Ebenezer Road, Florence, SC 29501, 843-664-4394, www.esab-cutting.com.

HIGH PERFORMANCE FIBER LASER/PLASMA COMBINATION CUTTING

Manufacturers have been demanding a faster, more accurate way of producing cut parts and the experts at Messer Cutting Systems, Inc. (Menomonee Falls, WI) were happy to accept the challenge. The MetalMaster Xcel features state-of-the-art industry leading traversing speeds of 3,000 ipm and a robust design with high acceleration drives. Multiple tools can be added, including plasma beveling, oxyfuel, combination plasma/fiber laser cutting, drilling, and marking coupled with OmniWin software. Its rugged construction and proven technology leads to long-term durability.

The system features high performance 1,800 ipm at .5 g, with lifters that can accommodate all types of varying plate conditions. This machine features patented Slagger® self-cleaning table yielding maximum performance by reducing table cleaning time from hours to minutes. This is coupled with a professional menu driven, feature rich, “Global Control Plus” CNC that easily makes every machine operator an expert.

Messer Cutting Systems, Inc., N141 W9427 Fountain Boulevard, Menomonee Falls, WI 53051, 262-255-5520, Fax: 262-255-5170, www.messer-cs.com.

LASER MARKING SYSTEMS

MOBILITY IN LASER MARKING

The TruMark 5010 Mobile Marker, an innovative portable laser marking unit from TRUMPF Inc. (Farmington, CT) features a compact and handheld marking head. The operator simply moves the laser marking unit to the work piece, eliminating the need to move the part, and intelligent sensors help guarantee the entire process is conducted safely and accurately.

Unlike conventional methods, the laser marking process is achieved without special tooling or consumables. As a tool, the laser is extremely flexible and is capable of marking identifying characters and images including barcodes, variable text, and data matrix codes. The TruMark 5010 Mobile Marker can also handle simple cleaning tasks and can prepare small areas for processing.

A fiber laser operating in the infrared spectrum forms the heart of this marking system. A laser light cable guides the beam from a mobile frame which holds the laser, safety controls and suction system, to the scanner unit at the workpiece. When the operator positions the TruMark 5010 Mobile Marker, a vacuum is created which hermetically seals any gap between the machine and the component. If the processing head is not properly positioned, sensors prevent the laser from emitting its beam. This guarantees that the operator cannot inadvertently start the laser.

The Mobile Marker also features an integrated vacuum unit which removes any vapors or materials dislodged during the marking process. In addition, the unit’s compact design and low weight permit not only straightforward manual operation, but also integration into assembly lines.

Fast and flexible describe the TruMark 5020. High pulse frequencies and superior pulse-to-pulse stability make this fiber laser marker the ideal solution for metal or plastic applications where high speed and superior edge quality are required. Its highly dynamic scanner module is able to convert pulse frequencies of up to 1 megahertz into a correspondingly high processing speed. In turn, thanks to MOFPA technology (Master Oscillator Fiber Power Amplifier), the pulse duration of the TruMark 5020 can be adjusted so that laser processing is perfectly adapted to the application. In addition, the laser’s focus point adjusts to the different component heights. The TruMark 5020 shows special strength in marking metal by delivering high quality customized marking or engraving in short processing times.

The TruMark 5020 is designed with a special focus on laser safety and features a fiber protection hose with a mechanical lock to prevent the laser beam from discharging between two marking procedures.

Telediagnostics makes it possible to maintain the fiber marking laser remotely with comfort and security. For this purpose, the TruMark 5020 comes with integrated laser power measurement and laser power calibration – features that have been proven to maintain laser marking consistency.

TRUMPF Inc., Farmington Industrial Park, 111 Hyde Road, Farmington, CT 06032, 860-255-6000, Fax: 860-255-6424, www.us.trumpf.com.

ENHANCED LASER MARKER SOFTWARE

Miyachi America Corporation (Monrovia, CA), a leading manufacturer of welding, marking, cutting and micro machining equipment and systems, has updated their LMF series’ laser marker software and control card for improved graphic file editing (GFE) and enhanced functionality for production line operation. The updated software and control card allows for the control of up to 4 axes of motion without the need for a dedicated PC, saving space and simplifying integration into production lines.

The new card also features an improved ability to mark QR codes and TrueType fonts. The improved GFE enables users to size, shape and edit graphic files such as .dxf and .dwg within the marking software’s graphical user interface giving users the freedom to adjust node locations, close paths, and more directly modify graphic files without adding third-party software. These new features are now standard in all new LMF series markers. Existing markers may be upgraded by Miyachi America service personnel, in the field. Contact the company to schedule a field service visit.

Miyachi America Corporation, 1820 South Myrtle Avenue, Monrovia, CA 91016, 626-303-5676, www.miyachiamerica.com.

LASER CUTTING ACCESSORIES & SERVICES

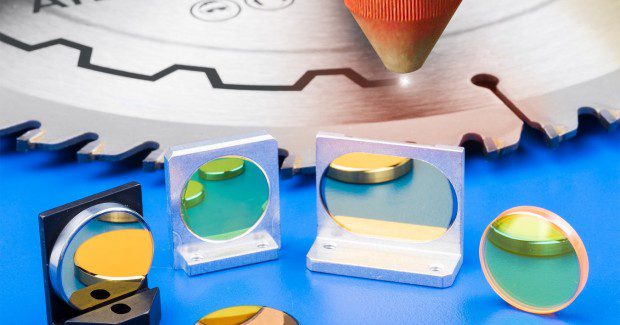

OVERSTOCK CUSTOM LASER OPTICS

A new Overstock Custom Laser Optics parts list featuring several hundred different configurations of optics available for overnight delivery has been introduced by Laser Research Optics (Providence, RI). The list includes over 400 types of lenses, turning mirrors, output couplers, beam splitters, beam combiners and more that are first-quality optics resulting from production overruns. Materials include ZnSe, fused silica, copper, silicon, and germanium in 0.5 in to 2 in OD and 15 mm to 50 mm OD sizes, and in odd metric sizes in varying thicknesses, coated and uncoated. The Laser Research Overstock Custom Laser Optics list includes quantities offered and prices.

The company also carries a full line of OEM compatible, field-replacement CO2 laser optics supplied plain or mounted for popular marking and engraving lasers that are available for overnight shipment. Featuring < 0.2 percent total absorption values, these Optics are offered with various phase and polarization coatings. Lens sizes from ½ in to 1-1/2 in OD and ¾ in to 3 in OD for mirrors are available for Camtech®, Emission®, Epilog®, Ferba®, GCC laser Pro®, Gravograph®, Jamieson®, Kern®, Pinnacle®, LST Lasers®, Synrad®, Trotec®, Universal® and Vytek® lasers. CO2 Lenses and Mirrors are priced according to configuration and quantity; with delivery from stock within 24-hours.

Laser Research Optics, a division of Meller Optics, Inc., 120 Corliss Street, Providence, RI 02904, 888-239-5545, Fax: 401-331-4004, www.laserresearch.net.

HIGH ACCURACY, THERMALLY STABLE GALVO SCANNER FOR PRECISION LASER PROCESSING

Aerotech Inc. (Pittsburgh, PA) has introduced a high accuracy, open frame, thermally stable galvo scanner for a wide range of laser machining and etching applications. The Nmark AGV-HPO scanner attains single-digit, micron-level accuracy over the field of view and offers industry-leading resolution of >24 bits when used with the Nmark CLS controller.

The scanner’s multiple input apertures and mirror coatings support a variety of laser wavelengths. Its open-frame design reduces cost and allows for more flexible laser beam delivery. The AGV-HPO is available with right-side and left-side input apertures for “mirror image” machine builds or side-by-side scanner mounting with a single laser beam split to source both scanners.

Aerotech, Inc., 101 Zeta Drive, Pittsburgh, PA 15238-2811, 412-963-7470, Fax: 412-963-7459, www.aerotech.com.

CAMERA REGISTRATION SYSTEM

Kern Laser Systems (Wadena, MN) is excited to announce the addition of k-vision to their current line of laser systems. The optional k-vision package is a fully integrated hardware and software solution that allows for accurate cutting of printed materials. This process starts with a nozzle mounted camera which automatically measures the dimensions between registration marks on printed materials. The system then uses these measurements and the registration marks of the original cutting file to compensate for distortion and rotation. The slight adjustments that k-vision makes to the cutting file results in a perfectly matched cutout in the material being processed. The entire camera system can be easily removed and stored in a protective box when not in use. The k-vision option is compatible with the entire Kern laser system lineup.

Kern Laser Systems, 1501 Industrial Drive, Wadena, MN 56482, 218-631-2755, Fax: 218-631-3476, www.kernlasers.com.

LASER DRILLING SERVICE FOR PRECISELY CONTOURED HOLES

A custom laser drilling service specializing in the fabrication of precise components requiring micro-holes that meet critical specifications is available from Advanced Laser Technologies (Stoneham, MA). The ALT Micro-Hole Drilling Service produces distortion- and stress-free holes as small as 0.010 in diameter with ±0.0005 in tolerance, depending upon the material, thickness and configuration.

Suitable for fabricating components where hole angles and the resulting airflow or fluid flows are critical, laser micro-hole drilling permits exact repeatability. ALT Precision Micro-Drilled Hole fabrication services are priced according to part configuration and quantity. Quotations are available upon request.

Advanced Laser Technologies, 74 Maple Street, Unit A, Stoneham, MA 02180, 781-438-6374, Fax: 781-438-5932, www.advancedlasertechnologies.net.

IOS APP CONTROLS FLATBED LASER

Trotec Laser, Inc. (Canton, MI) offers their iOS App, putting control of their laser systems in the palm of your hand. The Laser Remote App allows the operator to see current jobs and the remaining laser engraving and cutting times. With the virtual working area feature, positioning the laser head is only a tap. Receive status messages on completed or pending jobs to improve workflow. Notifications about job and laser status help to avoid production down-time. The App can be connected to a single machine or several Speedy lasers at once. With this intuitive operating tool, the company is setting new standards for laser systems.

Key features of the iOS App include:

- Remote control of the connected laser: Indication whether the laser plotter is running or waiting for new jobs.

- Laser operation: Pause running jobs and switch on or off the Trotec Atmos exhaust system.

- Laser positioning: Move the laser head using the virtual keypad or guide the laser head by touching the virtual working area.

- Calculation of engraving and cutting time: Get information about the total and remaining processing time of your laser job.

The App is available free of charge on the AppStore and is compatible with iPhone, iPod touch and iPad running iOS 6.0 and above. It requires Wi-Fi, Laser software Job Control X and a compatible Trotec laser system. The demo mode allows you to test the app without a machine.

Trotec Laser, Inc., 7610 Market Drive, Canton, MI 48187, 734-927-6304, Fax: 734-927-6323, www.troteclaser.com.

COST-EFFECTIVE LASER MARKING INTEGRATION

Technifor Inc. (Duluth, GA) offers PROFINET communication protocol in their laser marking equipment. With the implementation of PROFINET IO, these permanent laser marking machines can be directly connected to the industrial network without any additional devices. PROFINET, developed by Siemens and used worldwide, is the leading Industrial Ethernet standard and makes companies more successful by accelerating processes, boosting productivity, and increasing plant availability.

Thanks to this communication protocol, Technifor laser marking machines are becoming the most interconnected in the market. Their control units come with a full connectivity suite including generic I/O, dedicated I/O, Ethernet TCP/IP and RS232 that offer numerous possibilities for information to flow with all the elements that make up their environment. With this new functionality, the marking machines are able to interface and easily be integrated into all production lines using a Siemens and PROFINET programmable logic controller (PLC).

From the user side, direct connection to industrial networks without using a gateway provides a huge time saver for the integrator while reducing the costs for machinery installation, engineering, and commissioning. PROFINET can also switch off unnecessary power consumptions of your machines and systems during standby periods, saving energy. This is the ideal solution for all production centers where flexibility and upgradability are at the forefront. The company takes this philosophy even further by providing its customers with ample practical information available online: integration instructions guide, sample of source code to enter into the PLC programming software and manuals. The PROFINET option is available for the full Fiber Laser range (TF410/TF420/TF430/TF450).

Technifor Inc., 2200 Northmont Parkway Duluth, GA 30096, 704-525-5230, www.technifor.us.

SOFTWARE DESIGNED FOR ENGRAVERS BY ENGRAVERS

Gravotech, Inc. (Duluth, GA), a large supplier of permanent marking and engraving technologies, offers GravoStyle™ 7 Build 4 – the latest version of their leading software for laser and rotary engraving machines that has become the reference software for multi-technology engraving systems. Thanks to a user-friendly and intuitive interface, this professional CAD/CAM platform allows novices and experts alike to get the most out of their equipment, from simple labels to the most complex engraving tasks.

A modular interactive toolbar enables users to customize GravoStylE to their specific needs, while application driven ‘wizards’ simplify the most complex engraving applications. Some of the features available in this software include:

- Industry: dials, scales, multi-label matrix with automatic serialization and variable list import

- Signage: letter cutting with material-saving nesting, DDA/ADA compliant Braille translator

- Personalization: photo engraving, handwriting / doodles engraving

As a complete engraving solutions manufacturer, the company designs both their own software and engraving machines to guarantee maximum integration and efficiency. The new GravoStyle 7 takes this philosophy even further: the EDP™ concept greatly simplifies the laser cutting process by integrating machining parameters pre-defined for a wide variety of materials, while the new Print&Cut feature enables the precise cutting of printed material thanks to the automatic recognition of the picture.

Gravotech, Inc., 2200 Northmont Parkway, Duluth, GA 30096, 770-623-0331, Fax: 770-814-7203, www.gravograph.us.