Transforming the Way Material is Cut

A review of some of the newest laser cutting systems, laser marking equipment, and related accessories and services now on the market.

Posted: February 2, 2015

LASER CUTTING SYSTEMS

ADVANCED 3D LASER FOR AUTOMOTIVE PRODUCTION

Automotive parts manufacturers need highly specialized equipment for trimming formed sheet metal components while meeting all their specific requirements. The Laser Next machine from Prima Power (Arlington Heights, IL) draws on the company’s experience in the hot stamped steel industry. Collaborating with customers and partners operating in the automotive industry resulted in the design of a fast, compact and highly efficient 3D laser for high volume automotive production applications.

The company has been steadily increasing the performance of its 3D laser machines for automotive applications. The Laser Next represents a step change in this development cycle. Productivity on a typical benchmark component (B-pillar) has been raised by 25 percent. This means that four Laser Next machines can produce the same as five of the previous model.

The technology in the Laser Next gives it the best dynamic performance of any 3D laser on the market, with 208 m/minute trajectory speed and 2.1 g acceleration. Its advances in machine design include direct drive motors and transducers for the main axes and focusing head. Its compact design makes it possible to site four Laser Next machines in the same area as would be occupied by three of the previous model. There is no need for special foundations for these machines. For multi-machine configurations up to three Laser Next machines can be sited next to one another, all connected to the same magnetic scrap conveyer to deliver astonishing productivity per square meter.

To achieve improved Overall Equipment Efficiency (OEE), the company has used its know-how from hundreds of installations dedicated to the 24/7 manufacture of stamped high strength steel and of hydroformed automotive components. By examining every detail of the process, the design of the Laser Next has been optimized to maximize machine uptime, reduce non-productive times, minimize and simplify maintenance and consider the need for specialized resources dedicated to these activities.

Laser Next has a work volume of 3,050 mm x 1,530 mm x 612 mm and is equipped with 3 kW or 4 kW high brilliance fiber laser. Its compact focusing head, fully sealed for best protection, features direct drive motors, double protection SIPS, fully metallic sensor, and Focal Position Control. Its high-precision and dynamic turntable with servo motor and absolute encoder is designed to ensure the highest reliability, safety and ergonomics. Thanks to reduced blocking times, the distance between table and light curtains is very short for faster and more comfortable loading/unloading operations in full safety.

Prima Power North America Inc., 555 W Algonquin Road, Arlington Heights, IL 60005-4411, 847-952-6500, Fax: 847-952-6590, www.primapower.com/us.

DYNAMIC 3D LASER CUTTING OF COMPLEX PARTS

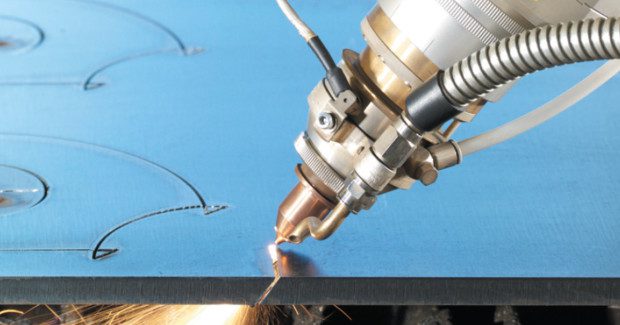

The robot-based laser machine JENOPTIK-VOTAN® BIM (Beam in Motion) from JENOPTIK Laser Technologies, LLC (Brighton, MI) provides industrial manufacturers with a highly flexible, fast and cost-effective solution for the processing of metals. Various companies from the automotive industry, where this technology has already been qualified, rely on it.

The heart of this laser cutting system is a laser robot arm in which the laser beam delivery is fully integrated. The laser beam is coupled in through the robot foot so that the transport fiber does not need to be moved within the working space. This not only minimizes the costs of maintenance and renewal, but the system itself is also minimized. The small laser cutting head that weighs only 5 kg can easily access even the narrowest areas. This is the only way to achieve the high path accuracy and the very high level of system dynamics necessary for 3D processing.

With a repeat accuracy of ±50 µm this laser machine ranks among the most precise systems of its class. Moreover, the axis movements of the laser arm are up to 60 percent faster than the current standards, thus allowing for a significantly shorter cycle time compared to other robot systems. One key objective in the continuous further development of this system is to increase capacity while minimizing the size of the machine at the same time. The aim is to simplify its integration into production lines or combined processing units such as cutting/welding systems.

The JENOPTIK-VOTAN BIM components have a modular structure so that they can be arranged within the space flexibly to suit the processing task. As an alternative, they can also be mounted on a platform measuring about 12 sq m and accommodating the robot, the laser, the switch cabinet and a turntable that supports maneuverable sequences and continuous cutting. Hence, the entire system can be transported and positioned easily using a forklift truck which helps to minimize installation time.

In order to achieve an optimal result for a variety of applications, more system variants are available in addition to the compact JENOPTIK-VOTAN BIM individual plant. These variants are based on the BIM robot module that has an open interface for integration into an overall plant concept. Possible variants are a system with a feeding robot conveniently holding a 3D-shaped tube or other part in front of the processing robot, or a multi-robot system. In this way, it is possible to set up a highly productive processing system comprising several robots and using minimum space, where the robots can work on a part simultaneously, thus providing maximum flexibility and enhancing performance.

JENOPTIK Laser Technologies, LLC, 8020 Kensington Court, Brighton, MI 48116, 248-446-9540, Fax: 248-446-9580, www.jenoptik.us.

EFFICIENTLY CUT ALL SORTS OF MATERIALS AND THICKNESS

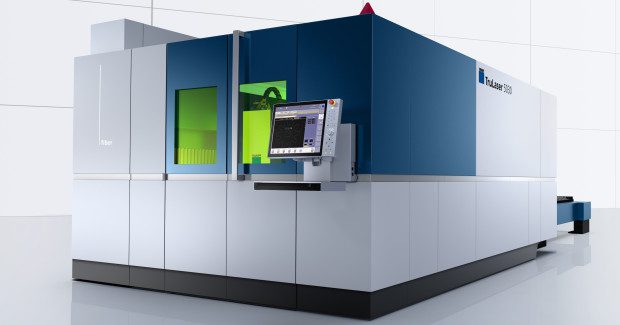

The TruLaser 5030 fiber from TRUMPF Inc. (Farmington, CT) is the first 2D laser cutting machine available with an 8 kW TruDisk laser. The increase in laser power significantly boosts productivity when processing medium and thick sheet metal.

Its BrightLine fiber, CoolLine and enhanced PierceLine functions guarantee high-quality laser processing in thicker materials as well. CoolLine, a new feature for solid-state lasers, stabilizes the cutting process in steel by use of targeted cooling. This results in greater material tolerance while enabling more intricate material contours and a tighter layout of parts. The new PierceLine function with improved piercing capabilities enables the laser to process smaller contours while significantly boosting speed.

Smart Collision Prevention and the Drop&Cut options further increase the efficiency and reliability of laser processing for 2D laser cutting machines. With Smart Collision Prevention, the risk of collisions during laser cutting is minimized. The function analyzes the cutting process to determine where cut parts are likely to tip and adjusts the processing strategy to accommodate. This can most often be achieved without adding microjoints to the part and can significantly reduce downtime caused by collisions. When coupled with the smart nozzle function with integrated nozzle inspection feature and the enhanced PierceLine piercing process, Smart Collision Prevention assures maximum process reliability for the TruLaser 5030 fiber. This substantially expands machine capacity while reducing the need for consumables.

The Drop&Cut feature aids in cost-effective production and enables operators to easily use part skeletons for additional production. Operators are provided with a live image of the machine’s interior on the control unit’s user interface. From the control unit, the operator simply clicks or taps the screen to drag the programmed contour to the desired location on the projected sheet and initiates the cut. With the new TruLaser 5030 fiber, the process is conveniently managed from a new and ergonomic 19 in control panel that can be adjusted to any height.

The TruLaser 2030 fiber with the energy-efficient fully integrated 4 kW TruDisk laser offers flexible and economic laser processing across a variety of materials and thicknesses. With a 59 in x 118 in working range, the machine achieves optimum energy efficiency with minimal space requirements.

The TruLaser 2030 fiber is controlled by a user-friendly touch screen interface which graphically displays the program and all essential information – keeping operators in control, regardless of their experience level. These and other features make it the ideal choice for fabricators in need of productivity and process reliability at a competitive investment and operating cost.

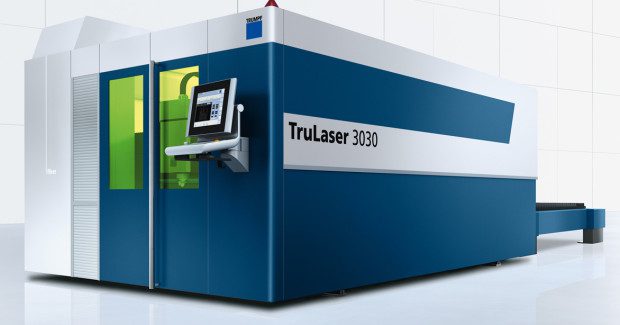

Powered by a fiber-guided TruDisk 4001 laser, the TruLaser 3030 fiber laser cutting machine is a flexible, productive and universal choice for high-quality laser processing across a wide range of material types and thickness. Its four kilowatts of power at a one micron wavelength enables the laser to cut up to 0.8 in thick steel with high productivity, fast positioning speeds and low energy consumption. It is also able to process 0.325 in thick non-ferrous materials such as copper and brass.

The TruLaser 3030 fiber is designed to be simple and self-explanatory, the machine is operated from an ergonomic swiveling operator console. The universal cutting head can process all sheet thicknesses, eliminating the need to change processing heads between applications. The TruLaser 3030 fiber is built with the highest regard for safety. The enclosed frame ensures absolutely no laser light escapes, yet large certified safety screens allow the processing area to be clearly visible at all times. The machine is also available with a wide variety of automation solutions, further increasing its level of productivity.

The TruLaser Cell 3000 is a versatile 5-axis laser machine for fine cutting and precision welding that offers cost-efficient laser processing of 2D or 3D components, producing high quality results on small or medium sized components. The highly precise TruLaser Cell 3000 is the ideal solution for processing a wide range of applications, from one-off prototypes to high-volume production. With solid-state laser options, available with up to 8 kW of laser power, the machine is also well-suited for processing nonferrous metals.

Processing metals is simple since the focal position is automatically adjusted to the thickness of the sheet metal. It is also possible to expand the diameter of the focus. This enables fabricators to cut materials of different thicknesses or to switch between welding and cutting applications without changing the focusing optics. The TruLaser Cell 3000 requires only a minimum floor space since the electrical control, cooling units and laser optics are all integrated into the machine. Its modular design allows the laser machine to adapt to different requirements in the production environment.

TRUMPF Inc., Farmington Industrial Park, 111 Hyde Road, Farmington, CT 06032, 860-255-6000, Fax: 860-255-6424, www.us.trumpf.com.