Put On Hold

The increase in higher precision machining is creating demand for stronger, more durable, faster acting, closer tolerance chucks and collets that can grip and hold the parts and the tools being used. Here is a review of some of the latest chuck and collet solutions that meet that demand.

Posted: February 27, 2015

Jaw forming rings are available for 5 in, 6 in, 8 in, 10 in and 12 in power chucks. They are capable of a wide range of OD and ID jaw formation. Self-centering action provides equal pressure on all jaws. The Dillon jaw forming ring is the only tool of its kind to compensate for “jaw lift,” even in worn chucks, which results in better parts concentricity.

Dillon Manufacturing manufactures a complete line of standard and custom workholding solutions including chuck jaws, chucks, vises jaws, soft jaws, hard jaws, collet pad jaw systems, chuck lubrication, and more. With ample production capacities and processes, the company is ISO 9000:2008 registered and can manufacture large production runs of special jaws with the same speed and accuracy as the smaller production lots. All products are made in the U.S.

Dillon Manufacturing, Inc., 2115 Progress Drive, Springfield, OH 45505, 800-428-1133, [email protected], www.dillonmfg.com.

COLLETS

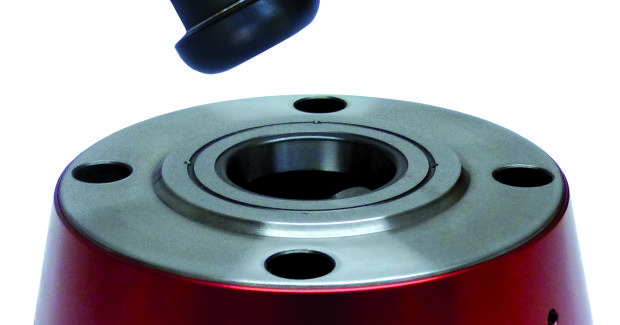

MODULAR COLLET CHUCK BRINGS FLEXIBILITY TO TURNING

Röhm Products of America (Lawrenceville, GA) offers the modular CAPTIS workpiece clamping system, which provides a wide range of workholding options for turning, milling and drilling applications through different combinations of modular components. An innovative quick-change method permits conversion from external to internal clamping in less than a minute, and collet changes can be made in 15 seconds. It is compatible with the industry standard BZI collet interface. The CAPTIS system produces strong clamping forces without deformation of delicate workpieces while offering high repeatability and minimal run-out.

Different configurations of the CAPTIS system deliver a variety of workholding functions:

- The power-operated, rotating CAPTIS collet chuck is designed for use in turning machines. Its compact size facilitates full use of a machine’s work envelope.

- CAPTIS-D is equipped with axial tightening for machining bar stock and can be easily converted to the CAPTIS-A, which is ideal for flange-type workpieces and includes workpiece stop and hold-down features.

- CAPTIS-AF, with an axially fixed (dead-length) collet and optional workpiece stop, is ideally suited for delicate workpieces, short clamping surfaces and use in counter spindles.

- The stationary CAPTIS-MS collet chuck is intended for use in drilling, milling and machining centers and for manual machining. Operated manually with hydraulic power intensification, the chuck can be optionally equipped with a front or internal stop.

Headquartered in Lawrenceville, Röhm Products of America, a division of the Röhm Group, has been a leading provider of high-quality clamping and gripping technologies to the North American metalworking industry since 1978, with a broad and powerful product portfolio of drill chucks, live centers, lathe chucks, vises, automation technology, power chuck technology, mandrels, tool clamping systems and customized solutions for turning, milling, drilling and grinding applications. The company also provides world-class support and services to ensure trouble-free machining processes within the aerospace, automotive, energy, engineering, micro technology and rail vehicle manufacturing sectors.

Röhm Products of America, Inc., 5155 Sugarloaf Parkway, Suite K, Lawrenceville, GA 30043, 770-963-8440, Fax: 770-963-8407, www.rohm-products.com.

UNIVERSAL HIGH-PRECISION COLLET CHUCK

Manufacturers of high-precision components in aerospace, transportation, die and mold, general engineering and other industries wage a constant battle between producing high-tolerance parts and a “we-have-to-have-it-tomorrow” reality. WIDIA Products Group and Services (Latrobe, PA) offers a significant weapon to bring shops closer to victory with a universal high-precision collet chuck that can be used in milling, drilling, reaming, and tapping applications while maintaining runout accuracies of 0.003 mm (0.0001 in) at 3xD.

Shops looking to upgrade performance and final part tolerance will welcome this chuck’s features:

- Added versatility – the ability to continue using standard ER collets while upgrading to precision collets.

- Thicker chuck walls and a stronger outer form for added rigidity and lower vibration for longer spindle and tool life.

- Unique sealed-by-design precision collets (6 mm to 20 mm or 0.24 in to 0.79 in) for excellent coolant delivery and longer tool life.

- Better and repeatable balancing, all contributing to higher accuracy.

Aerospace, die/mold and many other industries regularly encounter high-strength, difficult-to-machine materials requiring high torques, feeds, and forces. The danger of milling cutters being pulled out of the tool holder at these extreme forces has significantly increased. This is at least true for tool holders that offer precision clamping with good concentricity such as shrink-fit. Such toolholders work with frictional locking, but their clamping force is often not sufficient for roughing.

In response, this universal precision collet is available with Safe-Lock™ pull-out protection from Haimer. Helical grooves are ground into the shank of the milling tool that, together with the respective pin drivers in the chuck, prevent the tool from spinning or being pulled out of the holder altogether under extreme machining conditions. The helical path of the Safe-Lock grooves also allows for adjusting tool length, meaning tools can be reground and pre-set as usual.

Extreme challenges require the right tools, and the highest-performing tools require the best components. The HydroForce HT™ universal hydraulic chuck is a high-performance, high-torque universal hydraulic chuck. “The right chuck maximizes tool life, workpiece surface quality and production flexibility, and this is the most advanced hydraulic chuck available – a first-choice solution for all rotating applications,” says Doug Ewald, a global product manager at WIDIA.

With a more compact and stable design, featuring a 40 percent thicker front wall cross-section, HydroForce HT provides the increased rigidity necessary for improved cutting parameters and better results. Clamping force is up to three times better than regular hydraulic chucks, and with improved vibration dampening, runout is three microns at 2X diameter overhang. Balance quality of G2.5 is achieved at speeds up to 25,000 rpm. “All of this robust performance is available in a high-torque chuck requiring only two sizes for all your rotating tooling tasks,” adds Ewald. “Direct clamping is available for 20 mm and 32 mm (0.75 in and 1.5 in) diameters and reducer sleeves are applied for all other diameters.”

More cost-effective than expensive thermo shrink-fitting operations, up to four times more clamping force compared with collet chucks, and higher balancing quality performance than power milling chucks, HydroForce HT is a cost-effective universal chuck solution that simplifies inventory while maximizing tool life and machining results for milling, drilling, reaming, and other rotating applications.

WIDIA Products Group and Services, 1600 Technology Way, Latrobe, PA 15650, 724-539-5000, Fax: 800-323-7259, www.widia.com.

COLLETS ACCOMMODATE SHORT AND LONG TOOLS

Rego-Fix Tool Corporation (Indianapolis, IN), the inventor of the original ER collet system and a world leader in the manufacture of Swiss precision tooling, has expanded its powRgrip® product line with the introduction of PG-S short shank and PG-L long shank powRgrip collets. The additions facilitate use of shorter and longer-length carbide cutting tools. To conserve carbide, many U.S. toolmakers are producing tools that are shorter than European/DIN equivalents. At the same time, some Asia-region and other customers prefer tools that are longer than European tools.

For the shorter tools, PG-S collets have 3 mm to 6 mm shorter engagement than standard PG collets. PG-S collets permit use of off-the-shelf cutting tools instead of specials and also provide more latitude for regrinding. PG-L collets accommodate longer tools by providing 3 mm to 6 mm longer engagement than standard collets. PG-S collets are available in PG 6, 10, 15, 25 and 32 sizes, while PG-L collets are available in PG 15, 25 and 32.