Prime Time Player

The advanced machining methods used by this shop deliver machining times that are two-three times quicker than previously possible for tough, complex aerospace components.

Posted: February 10, 2015

Advanced Manufacturing Sheffield Ltd (AML; Rotherham, UK) is an advanced sub-contract machinist that specializes in the manufacture of hard, complex metal parts. The shop works collaboratively with major players in the aerospace industry and delivers parts on a reoccurring basis to these Primes by using processes that can cut metal significantly faster than many other suppliers, yielding benefits to its customers at the new product introduction phase.

These advanced methods eliminate the need for incremental learning of changes to processes. AML delivers instantaneous returns for its clients, saving costs which would normally need several years to be recovered. These techniques, combined with exceptional machining flexibility offered by machine tools from DMG Mori Seiki Company, Ltd. (Coventry, UK), have enabled the company to grow substantially.

Formed in 2008, AML began to offer manufacturing, training and consultancy to aerospace Primes and Tier 1 suppliers. However, by 2010 it had extended its capabilities with its own manufacturing facility, producing critical parts such as blades, disks, blisks, and combustion casing components. The company is now a Tier 2 member of the The University of Sheffield Advanced Manufacturing Research Centre with Boeing (AMRC), and it benefits from a close technological relationship with that organization to continually enhance its advanced machining capabilities.

http://youtu.be/dgwpnEyYouk

Dr. Gareth Morgan, the managing director of AML, was one of the first ten people to work at the AMRC when it was formed in 2001 and, while there, used his knowledge and experience to develop many machining projects from concept validation to qualification of the full production process and its metrics. The realization that the AMRC could not offer commercial manufacturing to its customers led him to form AML to deliver this service.

By combining technology and experience from the AMRC, along with DMG Mori machinery, AML routinely offers its clients metal removal rates 2-3 times faster than could previously be achieved. Evaluation of machine tool performance was a common demand at the AMRC for Dr. Morgan: “DMG Mori always came out high on the list for machine uptime, service, rigidity and repeatability and, without these characteristics, it would be impossible for us to achieve the results we do.”

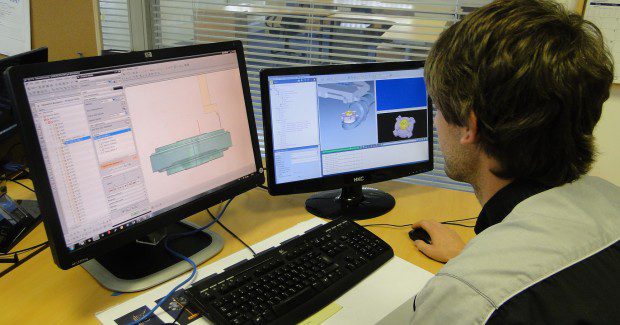

AML currently uses six DMG Mori machine tools: one NT5400, two NT4300s, one NMV5000 and two NMV8000s. The shop also has a Mitutoyo CMM, Factory Master MRP, NX CAD/CAM and Vericut. “We chose the machine tools for their 5-axis capabilities that give us maximum flexibility for the wide range of parts we produce,” explains Morgan. “My experience with these machine tools gives us insight into ways of maximizing their capabilities by optimizing factors such as workholding and cutting methods. Where necessary, we also have direct access to Japan through their dedicated service personnel for more advanced technological questions.”

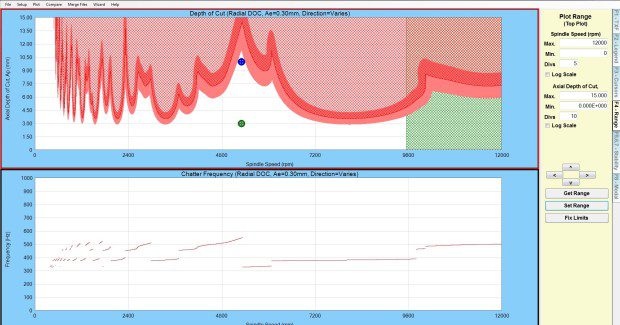

Specific techniques employed by AML include resonance measurement and adaptive probing. With resonance measurement, accelerometers are fitted to the cutter and, in some cases, the billet. Readings are then taken to establish the best cutting conditions and methods. By using this technology, the shop can maximize metal removal rates by taking much deeper cuts than would normally be possible and avoiding problems commonly found when cutting titanium, such as burning the tool and chatter that can damage the material and lead to high scrap rates.

“Resonance technology was the field of study for my PhD, so we are well advanced in its use,” explains Dr. Morgan. “For aerospace parts we work with aggressive materials and frequently remove over 80 percent of them, so this is a very important technique for us. The stiffness and dynamic vibration characteristics of the machine tools play an important role in making it highly productive.”

For adaptive probing the shop uses a sequence of measure and cut operations which, at each step, automatically feed information back to the machine control to adjust the next cut. “We rely on the repeatability of the tool changer and axes to make this work so that we can achieve tolerances on diameters of ±6µ, i.e., results that would normally require a grinding operation,” notes Dr. Morgan.

The flexibility of these machine tools enables the shop to finish parts in one operation so that they are ready to go into stores without any further benching operations. On one particular component, the shop was able to machine every feature, including a complex internal formed radius. “Hand dressing of features such as this internal radius inevitably leads to higher scrap rates as, with the quality demands of the type of components we produce, surface damage is unacceptable,” states Dr. Morgan. “By producing every feature of a component on the machine tool, we can achieve zero scrap.”

Nigel Lane, the chairman of AML, says, “For Tier 1 aerospace suppliers, stability of supply is a major factor, so avoiding problems during manufacture is key to a good relationship. The technology and equipment we use is aimed at eliminating uncertainty and at the same time shortening lead times and reducing cost. We are already recognized in the industry for our advanced capabilities. Our relationship with the AMRC and DMG Mori gives us access to extra resources, both in machining capacity and know-how, and we are currently developing plans for a 50 percent expansion in our manufacturing facility. The first stage is already underway with a new NMV8000 arriving within the next month.”

Advanced Manufacturing Sheffield Ltd, Poplars Business Park, Poplar Way, Catcliffe, Rotherham, S60 5TR United Kingdom, +0 1709-720-478, www.amlsheffield.co.uk.

DMG Mori Seiki Company, Ltd., 4030 Siskin Parkway East, Middlemarch Business Park, Coventry, CV4 4PE United Kingdom, +44 2476-516-137, Fax: +44 2476-516-136, www.dmgmori.com.