Ovens for Paint Baking, Heat Treating and Removing Deposits

Advanced industrial ovens and furnaces from Grieve are used for powder coating, curing, baking, drying, and other applications requiring the circulation of heated air.

Posted: February 24, 2015

The Grieve Corporation (Round Lake, IL) manufactures a broad range of industrial ovens and furnaces used for powder coating, curing, baking, drying, and other applications requiring the circulation of heated air. Some new ovens were recently installed at different customer facilities for:

PAINT BAKING

The No. 806 is a 500 deg F (260 deg C), electrically-heated walk-in oven that is currently used for paint baking operations. Workspace dimensions of this oven measure 72 in W by 96 in D by 78 in H, with 100 kW installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 10,000 cfm 7.5 hp recirculating blower provides combination airflow to the workload.

This walk-in oven features 4 in insulated walls, aluminized steel exterior and interior, removable top-mounted heating chamber and a fully insulated floor. The oven is built with all safety equipment required by NFPA Standard 86 for flammable solvents, including a powered forced exhauster, airflow safety switch and purge timer. Other controls on the No. 806 include a fused disconnect switch, digital temperature controller and manual reset excess temperature controller.

HEAT TREATING

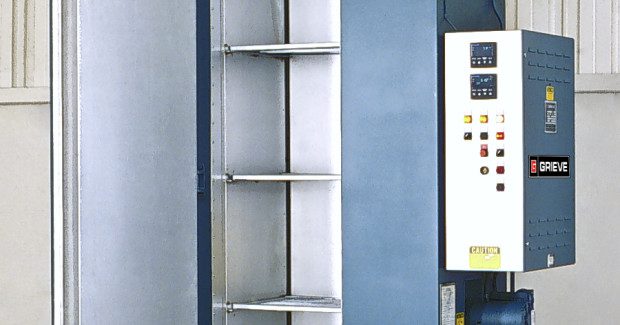

The No. 814 is a 500 deg F (260 deg C) electrically-heated cabinet oven that is currently used for various plastic and metal part heat treating operations. Workspace dimensions of this oven measure 22 in W by 21 in D by 85 in H, with 18 kW installed in Nichrome wire tubular elements to heat the oven chamber, while a 750 cfm, 3/4 hp recirculating blower provides a vertical downward airflow to the workload.

This cabinet oven features 4 in insulated walls, aluminized steel exterior and interior, three integral metal shelves, plus all safety equipment required by NFPA Standard 86 for handling flammable solvents, including a powered forced exhauster, airflow safety switch and purge timer. Other controls on the No. 814 include a fused disconnect switch, digital temperature controller and manual reset excess temperature controller.

DEPOSIT REMOVAL

The No. 975 is a 1,250 deg F (676 deg C) electrically-heated cabinet oven that is currently used for heating metal parts to remove deposits. Workspace dimensions of this oven measure 50 in W by 50 in D by 50 in H, with160 kW installed in Incoloy-sheathed tubular elements to heat the oven chamber, while a 6,000 cfm, 5 hp recirculating blower provides horizontal airflow to the workload.

This cabinet oven features 10 in insulated walls comprising 2 in of 1,900 deg F block insulation and 8 in of 10 lb/cf density rockwool insulation, top-mounted heating chamber, aluminized steel exterior, Type 304, 2B stainless steel interior and all safety equipment required for handling flammable solvents, including explosion-venting door hardware. The insulated floor of the oven is reinforced for 1,000 lb loading with a 1/4 in thick, Type 304 stainless steel plate.

The No. 975 controls include a digital indicating temperature controller and manual reset excess temperature controller with separate contactors.

The Grieve Corporation, 500 Hart Road, Round Lake, IL 60073-2835, 847-546-8225, Fax: 847-546-9210, [email protected], www.grievecorp.com.