Need a Lift?

Does your shop need to move heavy loads more effectively or position materials at work stations more efficiently? Here is a review of some of the latest equipment that can help you get the job done.

Posted: February 25, 2015

OVERHEAD CRANES UP TO 450 TON CAPACITY

Siemens Energy, Inc. (Charlotte, NC) selected Demag Cranes & Components Corporation (Cleveland, OH) as the overhead crane supplier for its Charlotte manufacturing operation expansion that included the completion of a 450,000 sq ft natural Gas Turbine production plant adjacent to its existing Steam Turbine-Generator plant. This is the only Siemens plant in the world that makes gas and steam turbines as well as generators. The facility also plays a key role in the important power plant service business. The Siemens Energy Sector is a leading global supplier of a complete spectrum of products, services and solutions for power generation in thermal power plants and using renewables, power transmission in grids and for the extraction, processing and transport of oil and gas.

Demag Cranes installed all of the overhead cranes used in this expanded operation, including several above 100 tons capacity with spans of almost 100 ft. Most of the cranes had multiple hoist arrangements for dual pick up and rotating parts, with main and auxiliary hoisting functions. Each crane was designed to meet the specific lifting and turning requirements of the manufacturing process. These cranes are used throughout the manufacturing and assembly process, from single part production to lifting, rotating, fine positioning, transporting and loading the completed gas turbine which can weigh more than 250 tons. “The cranes are integral to each step of the Turbine manufacturing process,” said Troy Starr, a manufacturing technician at Siemens Energy. “Demag supplied all of the small work station cranes, wall traveling jib cranes, everything up to the very large 450 ton crane.”

“This was a very challenging project and Demag, along with its installation team of Eastern Crane and System Specialties, completed the project within a tight schedule by coordinating closely with the production departments and the construction contractors,” stated Aaron Gooding, the Gas Turbine expansion project manager. The Demag Cranes Group is one of the world’s leading suppliers of industrial cranes and crane components and automation technology. The company manufactures equipment in 16 countries on five continents, has 6,115 employees and operates a worldwide sales and service network that is present in over 60 countries through its subsidiaries such as Demag Cranes & Components GmbH and Gottwald Port Technology GmbH, agencies and a joint venture.

Demag Cranes & Components Corporation, PO Box 39245, Cleveland, OH 44139-1895, 440-248-2400, Fax: 440-248-3897, [email protected], www.demagcranes.us.

ADVANCED ELECTRIC PNEUMATIC TIRE LIFT TRUCK

Mitsubishi Caterpillar Forklift America Inc. (MCFA; Houston, TX), the provider of Jungheinrich® lift trucks and narrow-aisle products in the United States, Canada and Mexico, has introduced the new 7,000 lb model capacity to its Jungheinrich large electric pneumatic tire lift truck series. Featuring advanced AC technology for increased performance and productivity, the new EFG 535k-S50 series features industry-leading lift speeds and increased energy efficiency.

Enhanced energy efficiency is a key advantage of the Jungheinrich EFG 535k-S50, which is equipped with the newest generation of 3-phase AC technology, resulting in increased productivity and the ability to run up to two shifts on a single battery charge in most applications. Additionally, these forklifts feature a maintenance-free braking system that uses regeneration, which turns momentum into energy and feeds it back into the battery. The Jungheinrich EFG 535k-S50 improves operator control through a comprehensive range of components for increased control, including responsive acceleration and braking, the EFG 5 series of lift trucks allow for precise positioning. Other key features include Jungheinrich Curve Control, which enhances operator control by automatically reducing the driving speed when the operator is turning corners.

The maintenance-free braking system features regenerative braking with the traction motor that allows for smooth, energy efficient deceleration. The automatically engaging parking brake ensures secure stopping, even on ramps. Its multiple wet disc brakes are highly sealed for extreme durability in harsh environments. Jungheinrich’s new generation of 3-phase maintenance-free AC motors impressively provide quiet and precise operation at all speeds, along with high torque for faster operation cycles. The lift features lifetime lubrication of main components. The motor, brake and gears are all integrated into the sealed drive axle, with dust and water protection to IP54.

The high performance of this lift requires a high degree of control. That’s why the EFG series includes a comprehensive range of control equipment for more secure operation. All hydraulic functions deactivate when the operator seat is not occupied. There is no roll-back on ramps or inclines with the automatic parking brake, even when the vehicle is switched off. Intelligent electronics ensure smooth travel/reversing and precise positioning, along with efficient communication between the truck and operator/technician through the highly informative, interactive display.

Superior operator comfort is provided through a spacious ergonomic operator compartment that allows for relaxed and productive operation, particularly beneficial at the end of long shifts. Operators will experience an extremely comfortable ride on rough or uneven floors with the combination of solid pneumatic tires, a full-suspension seat and floating cabin, SOLO-PILOT hydraulic lever control for easier operation and the ability to tilt and telescope the narrow steering column to suit their needs. All essential controls are located on the highly-adjustable armrest, allowing for easy, intuitive operator control. Operators have an outstanding view thanks to an innovative overhead guard design allows for optimized operator visibility, helping to reduce the risk of damage during operation, and optimized mast channel nesting and hose routing. The low, wide step with slip resistant tread ensures easy entry and exit.

Jungheinrich ranks among the world’s leading brands of material handling equipment and material flow technology, offering a comprehensive range of technologically-advanced forklifts and very narrow aisle lift trucks. Their forklifts are distributed through the extensive MCFA dealer network located throughout North America. Additionally, MCFA manufactures a number of these branded forklifts and supplies parts from five distribution centers located in California, Indiana, Michigan, Pennsylvania and Texas.

Mitsubishi Caterpillar Forklift America Inc., 2121 W. Sam Houston Parkway North, Houston, TX 77043-2305, 713-365-1000, Fax: 713-365-1441, www.mcfa.com.

PORTABLE ERGONOMIC WORK POSITIONERS

Verti-Lift, Inc. (Louisville, KY) offers a complete line of Portable Hydraulic and Pneumatic Work Positioners that are designed to improve ergonomics and product positioning. These units are the ideal solution to eliminate reaching or unnecessary operator movements during palletizing, de-palletizing, work station assembly or manufacturing operations, by including a heavy duty 360 deg rotating turntable. They are available in a variety of capacities, base and turn table sizes, as well as vertical travel. They are also available as stationary units. Features include:

- Accordion Skirts

- Oversized Platforms

- Pit Mounted Unit

- Portability Package

- Detent Stops

- External Power Unit

- PLC Controlled

- Foot Pedal Control

- Platform with Beveled Edges

The company also offers heavy-duty, hydraulic Tandem Scissor Lift Tables for applications requiring longer platform sizes. These lift tables feature a longer length platform to meet the application needs of manufacturing, processing and distribution operations where materials of greater length are being handled. Tandem Lift Tables are available with a variety of dimensions and weight capacities, as well as options for conveyor, portability and added safety.

The company also offers Auto-Hite Carts that automatically adjust so that workpieces are at the optimal operator height. Designed to maximize safety, productivity, and ergonomics, these spring-loaded, self-leveling products feature a 22 in to 26 in window of vertical travel, making them ideal for any associate or parts height requirement. These ergonomic carts contain no hydraulics, do not require electric or air, and require minimal maintenance. They are ideal for assembly line or sub-assembly operations for a wide range of industries.

Standard deck sizes are 20 in W x 20 in L through 20 in W x 30 in L, with custom sizes available. Capacity is up to 1,000 lb. Featuring a “J” hook spring bracket design, springs can be easily added or removed in seconds. These units come standard with 5 in casters to ensure ease of mobility. They can also be floor mounted for work cell applications.

Verti-Lift manufactures a complete line of standard and custom materials handling and ergonomic equipment, including hydraulic and pneumatic scissor lift tables, hydraulic and pneumatic tilters, hydraulic and pneumatic work positioners, turntables, operator lifts, 2-post vertical lifts, self-leveling carts, platform trucks, and work stations and much more. All equipment is made in the U.S. and is available through material handling distributors nationwide.

Verti-Lift, Inc., 5559 National Turnpike, Louisville, KY 40214, 502-361-0180, [email protected], www.verti-lift.com.

GAS CYLINDER EXCHANGE EASIER THAN EVER

Ziamatic Corporation (Zico; Yardley, PA) introduces the QUIC-RELEASE Horizontal Cylinder Lift, Model QR-CL-H, that makes it easier than ever to transport and change gas cylinders. The QR-CL-H lifts and lowers “M” through “J” gas cylinders so that personnel don’t have to — reducing the chance of costly strain or back injury during cylinder exchange. Once secured, the cylinder can be rotated 90 deg to facilitate loading under bench seats and other horizontally-aligned compartments.

A strictly vertical model, QR-CL, is also available. Heavy-duty wheels allow a single cart to service multiple vehicles or workstations. Lift operates off of a 12v rechargeable battery. A wall charger is provided with unit. The list price $2,444.50.

Ziamatic was founded in 1958 with the intention of providing the men and women of the fire services industry with products that make their profession safer and easier. Over 50 years later, the company remains a leader in SCBA bracket and ladder rack technology.

Ziamatic Corporation, 10 West College Avenue, Yardley, PA 19067, 215-493-3618, www.ziamatic.com.

AUTOMATED VERTICAL RECIPROCATING CONVEYOR SYSTEM

In response to demand for a safer material lift for automation duty applications, Wildeck, Inc. (Waukesha, WI) unveils the new FlexLoader™ VRC system, a fully-integrated vertical reciprocating conveyor (VRC) system that incorporates automated flush-mounted conveyors with either a straddle or 4-post VRC and Wildeck® Overhead Safety Gates at each level. This new system turns a basic vertical lift into a safer, more efficient and more automated material lifting system that seamlessly connects all levels of a work platform to make better use of the available space.

Unlike a standard VRC, the FlexLoader material conveyor system incorporates the full-featured AutoSenz® D-Series Overload Detection System (U.S. Patent No. 7,408,317) with automated horizontal loading and off-loading conveyors and Safety Gates at each level. This means the system is excluded from elevator inspections and provides code compliance in all 50 states. The FlexLoader VRC system improves the utilization of existing overhead cubic space and dramatically increases operational efficiency.

The integration of Overhead Safety Gates at the in-feed and discharge points protects workers from the equipment and open shaft-way and prevents loads from being inadvertently pushed into or down the shaft-way. The VRCs that are an integral component of this system have become the preferred choice for many users becuase they have more available safety features than any other VRC on the market and are designed from the start to provide safer lifting of any type of load. The conveyor system and VRC are custom designed as a fully-integrated system to meet the specific application requirements.

The automated flush-mounted conveyor can either be supplied by Wildeck or can be supplied by the customer and factory mounted at Wildeck. Having a flush-mounted conveyor at each level makes it easy to load and off-load the VRC using a pallet jack or fork truck. The FlexLoader sequence of operation is as follows:

- Materials are inducted / loaded with a pallet jack or fork truck.

- Safety gate is manually closed.

- Load is transferred to the next level.

- Safety gate is manually opened at the receiving level to off-load the pallet.

The standard control package includes Call/Send Stations at each level and the patented AutoSenz “D-Series” overload detection system with full diagnostics and programmable service reminder. A signaling system (lights and/or alarms) is available to warn that:

- System is in “Auto Mode”

- System is in “Manual Mode”

- System status

- Errors or faults

Separate “inbound” and “outbound” lanes can be set up at each elevation to provide “C-Load” “Z-Load” or “H-Loading” Patterns. All components of the system (VRC, Safety Gates, & Perimeter Guarding) are designed for Heavy Automation Duty, they all utilize state-of-the-art, but cost effective, controls and devices, and they are all designed with safety in mind.

The FlexLoader Automated VRC system is available through material handling dealers and systems integrators nationwide. Wildeck has 37 years as one of the largest supplier of industrial steel work platforms (mezzanines), VRCs (vertical reciprocating conveyor) and safety guarding products, all of which are “Made in USA” and are Crafted with Confidence at the modern manufacturing facility in Waukesha.

Wildeck, Inc., 405 Commerce Street, Waukesha, WI 53186, 262-549-4000, [email protected], www.wildeck.com.

SEPARATE HEAVIER GAUGES OF STEEL, HARD-TO-HANDLE SHEETS

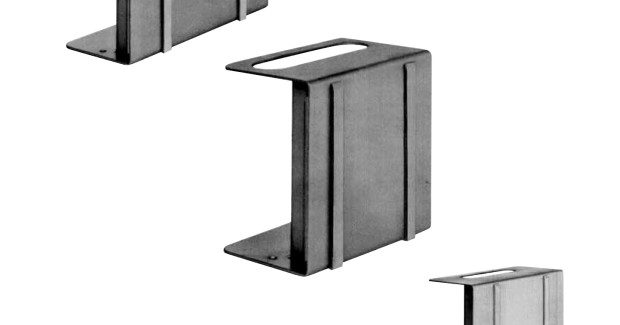

Sheet Fanners from Eriez® Manufacturing Co. (Erie, PA) feature a powerful magnetic circuit to easily fan and separate semi-sticky, oily, bent and heavy gauge sheet steel. They bring new efficiency to slow, costly, difficult sheet feeding to presses, brakes and shears. These Sheet Fanners increase production and reduce labor hours. With these units in operation, there is no prying required and doubles are eliminated. They also protect product quality because they will not mar painted or polished surfaces.

These Sheet Fanners are designed with hand cutouts, allowing them to be easily transported from one point to another. The sturdy base enables fast mounting to any flat surface. All units are built with a stainless steel “U” shaped frame with stainless anti-friction strips and back cover. The magnetic circuit is completely enclosed. It is rugged, tamper-proof and able to withstand severe usage. With three available strengths in four functional heights, the range of Sheet Fanners provide complete coverage for applications up to 1/8 in (3 mm) thick steel sheets stacked up to 14 in (355 mm) high. Select models are offered for next-day shipping through the EriezXpress® Program.

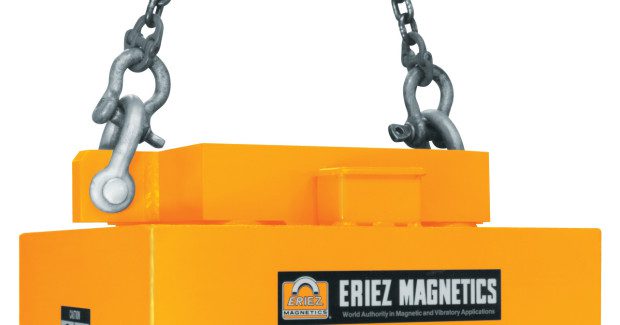

The company also offers Bi-Polar Lifting Magnets to safely lift and move steel without direct attachment by slings, hooks or cables. These magnets, available with a wide range of optional pole-plate configurations, are specifically designed to provide greater contact and holding strength for pipe, rounds, bundles, angles and shapes. They can be utilized in both single and multiple magnet applications. They are available in square and rectangular designs.

All Bi-Polar Lifting Magnets feature a deep, two-pole field for maximum holding force and weather-tight welded construction for ultimate durability. Special-shaped pole shoes and 100 percent duty cycle options are available. Offered in six sizes, Square Bi-Polar Lifting Magnets are an excellent choice for handling various bundled materials. Rectangular Bi-Polar Lifting Magnets come in three widths and 13 sizes. They are perfect for pipe handling, round bars, angles, flats and shapes.

Circular Lifting Magnets provide an inexpensive and effective solution for handling all types of steel, especially scrap. These general purpose magnets are frequently used in steel mills, steel service centers and ball mills for furnace charging and other material handling jobs. Circular Lifting Magnets – with advanced, computer-designed magnetic circuitry – offer a high lift-to-weight ratio. They provide a 75 percent duty cycle with 15 minutes maximum “on” time. Standard Circular Lifting Magnet models come in 18 in and 24 in (457 mm and 610 mm) diameter. All units feature weatherproof construction and Class H insulation. A triple-sealed terminal box and super-alloy steel chains are standard. Rectifiers, drop controllers and cable reels are available as accessories.

Eriez offers a complete line of Lifting Magnets in both permanent and electro designs with various models, sizes and strengths to handle many different lifting jobs. Eriez specialists are always available to consult on customers’ specific needs –whether it’s for a single magnet or a series of magnets engineered into an efficient materials-handling system to reduce costs.

Eriez is recognized as world authority in separation technologies, with magnetic lift and separation, metal detection, materials feeding, screening, conveying and controlling equipment have application in metalworking industries. The company manufactures and markets these products through 12 international facilities located on six continents.

Eriez Manufacturing Co., 2200 Asbury Road, Erie, PA 16506, 814-835-6000, Fax: 814-838-4960, [email protected], www.eriez.com.