High Bending Force for Thick Plates

PB plate bending machines from Schwarze-Robitec are ideal for precision bending of up to 200 mm thick plates for energy or offshore applications.

Posted: February 24, 2015

The demand for thick plates of high-quality materials is huge, particularly in markets that are flourishing like the energy or offshore sectors, where plates of up to 200 mm thickness are required. Due to its particularly stable design of the top roller, drive side and safety chuck side, the plate bending machine series PB from Schwarze-Robitec GmbH (Cologne, Germany) has the necessary bending force to bend such solid plates.

When employing these modern PB machines, there is only little excess material. This is a significant cost saving when one thinks of the plate thickness. Because, unlike the standard machines on the market, in the resource-saving PB machines the plates are completely clamped except for a small section, resulting in only minimal residual lengths of 1.5 times to two times plate thickness.

With no additional processing steps needed for bending the ends, production time is up to three times shorter. This work step is already carried out when clamping the plate in the machine, because the bottom rollers are fed to the top roller. A slight bending already occurs during this process and the forming process continues smoothly. A further advantage of this technology is that the long end does not protrude at the top of the machine, but at the bottom towards the floor. This provides a much higher occupational safety than conventional technology.

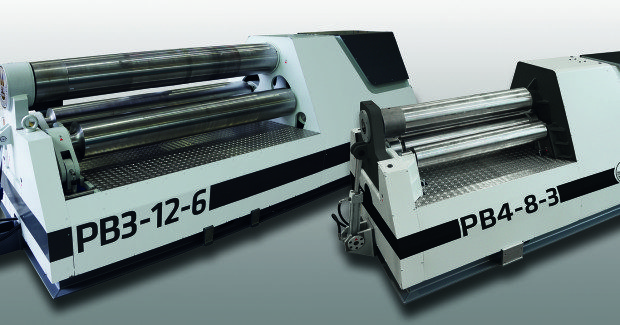

The machines of the PB series are optionally equipped with three or four rollers. While the version with three rollers represents a reasonable solution for manufacturers of smaller batch sizes and for the forming of variable plate thicknesses and widths, the four roller machines are ideal for series production. The newly developed CNC control “Seven” comes into effect here, which, thanks to the higher operator convenience, makes work noticeably easier and takes care of faster production processes.

Schwarze-Robitec GmbH, Olpener Straße 460, 51109 Cologne, Germany, +49 221 890080, Fax: +49 (221) 89 00 8-9920, [email protected], www.schwarze-robitec.com.