Etching Out New Advantages with Existing Laser Cutting Systems

Here are some ways to take full advantage of your laser cutting machines etching ability, from decorative purposes to part numbers.

Posted: February 2, 2015

Laser etching is primarily thought of as a job saved for a laser marking system. Although that may be the case for more intricate designs such as bar codes or multi-colored aesthetic artwork, an existing laser cutting system can handle many marking applications, giving fabricators the flexibility to streamline production processes and realize the full potential of their machine with just a slight increase in cycle time. Etching provides for easy implementation of assembly data, part information or other essential part marking, but to have the greatest success with laser etching, it is important to consider the factors that come into play.

DIFFERENCES IN CO2 AND SOLID-STATE LASER ETCHING

Laser etching is achieved by using low laser power and low pulse frequency to remove the upper surface of the material. One of the major differences between etching with a CO2 laser versus a solid-state laser is the type of material that can be processed. Due to the nature of the beam generation and the 10 micron wavelength produced by the CO2 laser, only minimally reflective materials such as steel, stainless steel, and aluminum can be processed by it.

Solid-state lasers generate a 1 micron beam wavelength which couples with materials more successfully than the beam produced by the CO2 laser. This gives solid-state lasers, such as fiber and disk lasers, the ability to process a much wider range of materials, including those with reflective surfaces.

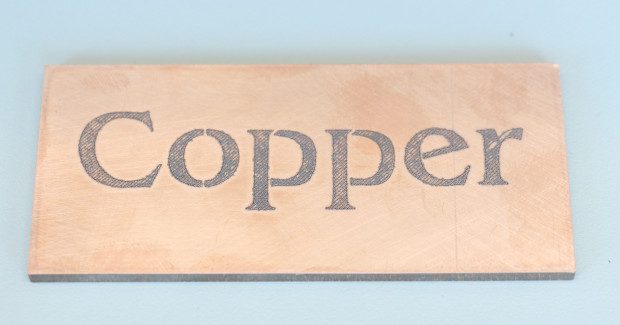

Since the wavelength of the solid-state laser beam is shorter than that produced by a CO2 laser, the solid-state laser’s waist (diameter of the beam at the focus point) is smaller. This gives solid-state lasers a higher power density and allows for greater absorption into the material. For this reason, solid-state lasers are able to produce a faster, higher quality result across a wider range of materials. The disk laser design adds an additional benefit: it is completely impervious to back reflection. As a result, highly reflective materials such as copper and brass can be etched safely and 100 percent reliably with this technology.

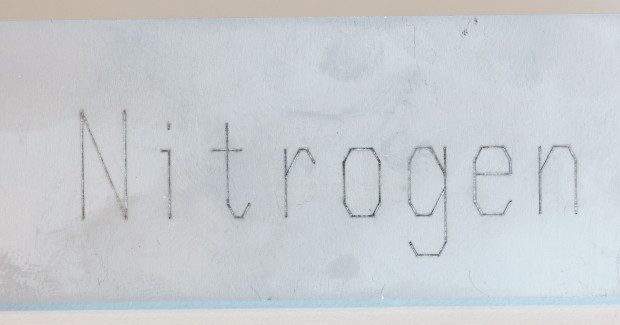

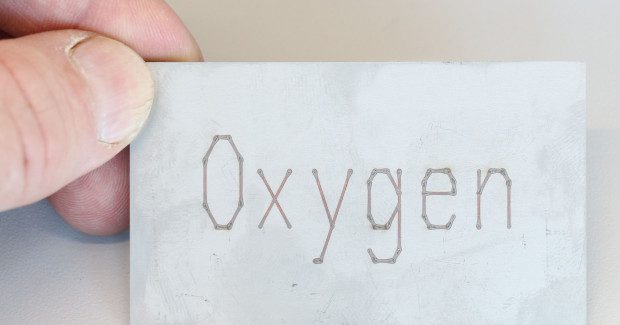

The resonator design also influences the type of assist gas that one should choose when laser etching. A CO2 laser tends to yield a superior etch when oxygen is used, while solid-state lasers demonstrate better results when etching is done with air or nitrogen. Although both laser types can etch with the various assist gasses mentioned, using the right gas with the right laser resonator will also provide for a cleaner etch overall.

DEFINING PARAMETERS AND TECHNIQUES

Varying the cutting parameters on your laser system will produce different etched styles, enabling fabricators greater flexibility in part marking. The best assist gas for an etch is not always the same as the one used when cutting. The choice should be based on the desired appearance of the etch. Using oxygen as the assist gas will usually produce a dark, highly visible etch, but when it is used with a solid-state laser on thin sheet material, it often leaves a burnt look in tight corners.

In this case, air is a good alternative. Air will result in a clean, yet dark etch. Using nitrogen assist gas will produce a colorless etch, and with etching speeds upwards to 500 ipm, the cycle time is very low. With nitrogen, the etchings may even appear shiny on materials such as stainless steel and aluminum.

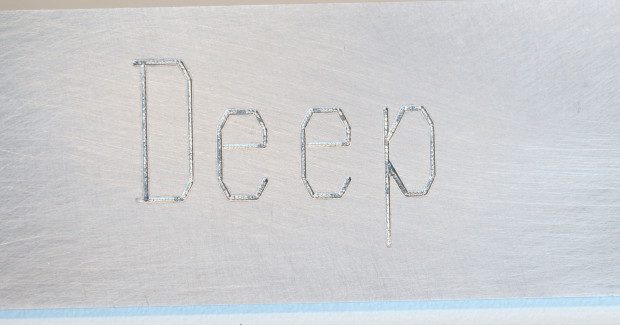

In addition to changing assist gas parameters, fabricators can improve the visibility of an etch by using a hatching method for the process. This is very popular when the end result is a decorative or contains lettering. Engraving or deep etching is also very common in the manufacturing world, for example, with parts that eventually receive a powder coating, or that will be tumbled in subsequent manufacturing steps.

For these applications, a deeper etch ensures the part number or other identifying information remains readable downstream. A deep etch can be achieved by moving the nozzle standoff closer to the part. Additionally, the fabricator can etch even deeper into the material by lowering the focus of the beam. This can be seen in the sample parameters for carbon steel on a solid-state laser below:

| Decorative Oxygen Etch | Medium Depth Etch | Deep Etch | |

| Power | 80 watts | 120 watts | 130 watts |

| Frequency | 600 Hz | 1,000 Hz | 600 Hz |

| Speed | 120 ipm | 80 ipm | 75 ipm |

| Gas | Oxygen | Oxygen | Oxygen |

| Gas Pressure | 0.8 bar | 0.8 bar | 0.8 bar |

| Nozzle Stand Off | 0.32 in | 0.32 in | 0.32 in |

| Focus | 3.5 mm | 3.5 mm | 1.0 mm |

ETCHING UNUSUAL MATERIALS

When etching galvanized steel, a double pass with the laser is best. The first pass removes the galvanized coating using nitrogen, and the second pass deeply engraves the material using air as an assist gas to make the mark more visible. This will ensure a visible etch can be seen even after the part has been powder coated.

| First Pass | 2nd Pass | |

| Power | 200 W | 100 W |

| Frequency | 600 Hz | 10 Hz |

| Speed | 120 ipm | 10 ipm |

| Gas | N2 | Air |

| Gas Pressure | 15 bar | 0.8 bar |

| Nozzle Stand off | 0.31 in | 0.5 in |

| Focus | -3.0 mm | -6.0 mm |

Highly reflective materials such as copper and brass can be etched safely using the solid-state disk laser technology. While copper and brass can be etched with air, nitrogen or oxygen, the choice impacts the degree of contrast seen in the material. Oxygen is the best choice when processing copper as it produces a dark etch that can be easily seen despite the material’s reflective surface. For brass, air produces the darkest and most legible result.

From decorative purposes to part numbers, laser etching is an important consideration in today’s manufacturing environment. By applying the information above you can take full advantage of your laser cutting machines etching ability. Starting with the sample parameters and tips given above makes it easy to begin or improve your current etching processes.