Catch the Wave(form)

Waveform turning, multiple machining sequence support, ribbon bar and interface updates, and the inclusion of Wire EDM are the newest CAD/CAM game changers that machine shops need to compete in a global economy.

Posted: February 9, 2015

The swift evolution of Edgecam Workflow highlights over 50 new and enhanced aspects of functionality in the latest release. Waveform turning, multiple machining sequence support, ribbon bar and interface updates, and the inclusion of Wire EDM mean that Edgecam 2015 R1, from Vero Software Ltd. (Cheltenham England), continues to be a game changer in ensuring that manufacturers can compete in a global economy.

Strategic product director Raf Lobato points out that this newest version of Edgecam also makes it available for turning strategies after having developed waveform roughing for milling during the last two years. Manufacturers say this will be particularly valuable in driving down costs. For example, Rob Duncan from Linkam Scientific Instruments Ltd. (Waterfield, UK) says, “We invested in a new mill-turn machine early in 2014 which is reducing cycle times. But using this new waveform toolpath generation for turning will make an even bigger difference.”

Here are some of the features:

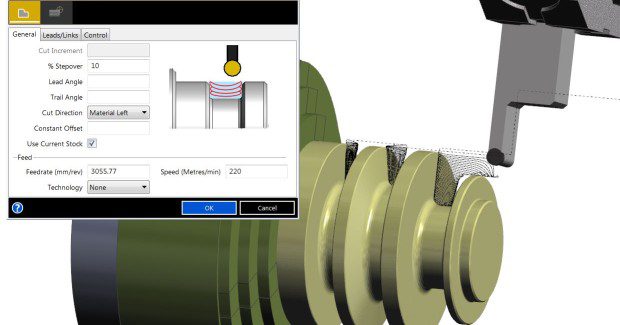

Rough Waveform Turning: Based on the successful milling waveform technology, Edgecam 2015 R1 introduces a brand new turning cycle, Rough Waveform Turning. The toolpath maintains a constant cutting load, enabling significantly faster cutting data, and prolonging tool life. Similar to other turning commands, the cycle is sensitive to the stock condition, eliminating ‘fresh-air cuts.’

Multiple Setup Support: The new release introduces further Workflow enhancements by supporting multiple setups in both the turning and milling environments. This means both the component and stock and fixtures can be passed to subsequent new, machining sequences. “This enhancement promotes the use of one single CAM file to house multiple machining setups, ensuring the stock remains associative between setups is a massive improvement,” explains Lobato.

Themes – Ribbon Bar Customisation: The default ribbon bar can be customised and saved as a ‘Theme.’ Themes can be exported to other Edgecam installations and deployed across networks. Users can personalise their individual theme with frequently used commands, even adding custom macros.

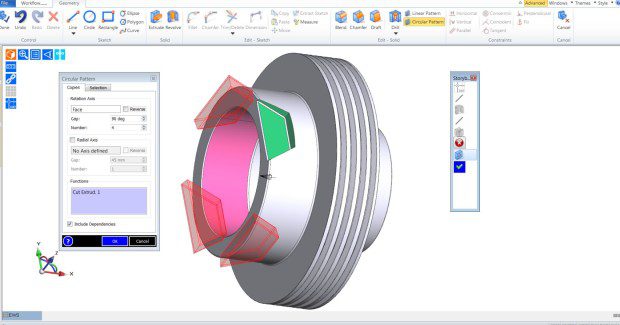

Edgecam Workflow Solids (EWS): Numerous new commands have been added to the internal solid modelling software. DXF and DWG files can now be imported to accelerate the design process. And both internal and external threads can now be created in EWS. An array of time-saving commands have been introduced, such as Copy/Move procedures and the ability to create circular workplanes.

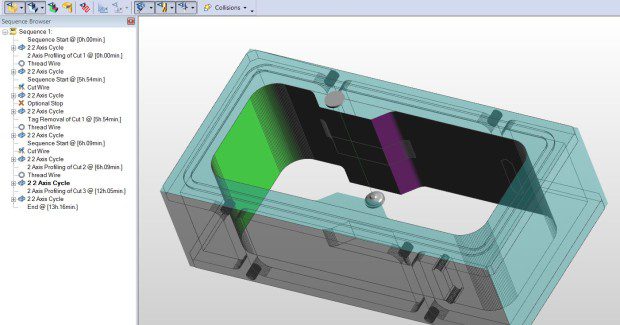

Wire EDM: The Wire EDM product is now available in the Workflow environment, and Edgecam 2015 R1 offers full machine simulation, including stock and cross-section display.

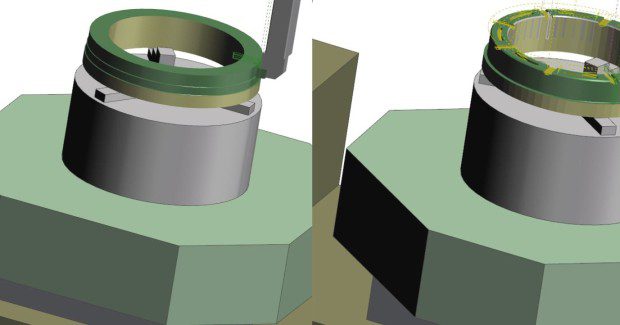

Turning on Milling Machines: A new machine tool configuration has been introduced, making it possible to turn on a milling machining centre. As well as accurate code output, full machine tool graphics are available for toolpath simulation.

Picking 3D Faces: The Parallel Lace, Constant Cusp, Rest Finishing and Pencil Mill Cycles have all been enhanced to allow ‘direct picking,’ meaning that individual faces or surfaces can be selected and without the need for creating boundaries the entire model will be protected against. “The reduction in the need to create boundaries is one of our primary drivers in making Edgecam quicker and easier to use,” notes Lobato.

New Engraving Cycle: The new machining command ‘Engraving Cycle, allows complex geometry corners to be shaped, and artwork profiles to be machined. Using direct picking, the cycle works with a variety of entities, and offers four different types of strategies.

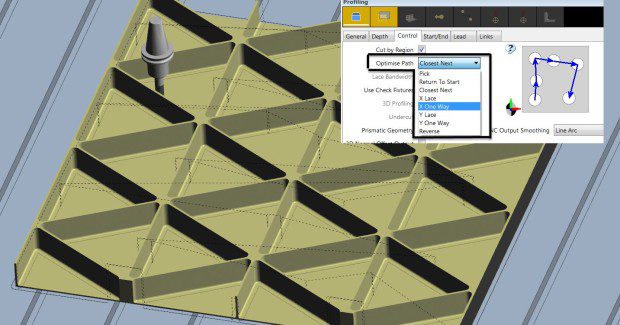

Ordering of Profiling and Roughing: An Optimize Path function has been added to both the roughing and profiling cycles, giving greater control over the toolpath. Specifically, users can save on wasted toolpath movements by dictating the order in which regions are machined.

“With the multiple setup support, waveform for turning, engraving, direct picking of surfaces and Wire EDM, there’s something for everyone in Edgecam 2015 R1,” adds Lobato.

Vero Software designs, develops, and supplies CAD/CAM/CAE softwarea that radically enhances the efficiency of design and manufacturing processes, providing users with exceptional value through high productivity gains and significantly reducing time to market. Its brands include Alphacam, Cabinet Vision, Edgecam, Machining STRATEGIST, PEPS, Radan, SMIRT, SURFCAM, WorkNC and VISI, along with the production control MRP system Javelin. Despite the diversity of applications, these solutions have one thing in common: they all address the rising challenges of achieving manufacturing efficiencies and bring huge value to the operations in which they are deployed.

The company has direct offices in the UK, Germany, Italy, France, Japan, U.S., Brazil, Netherlands, China, South Korea, Spain and India, all supplying products to more than 45 countries through its wholly-owned subsidiaries and reseller network. Vero is part of Hexagon, a leading global provider of design, measurement and visualization technologies that enable customers to design, measure and position objects, and process and present data.