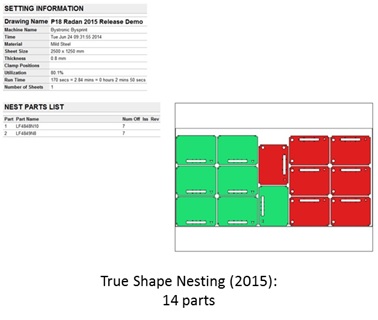

CAD/CAM Software Creates More Compact Nests

Radan 2015 from Vero Software spreads parts more evenly throughout the sheet, better utilizes the middle of the sheet, and automatically applies rectangular nesting for nearly-rectangular parts to maximize the sheet.

Posted: February 24, 2015

Radan 2015 is a CAD/CAM solution for sheet metal fabrication from Vero Software Ltd (Cheltenham, England) that offers 180 improvements, including nesting upgrades that increase productivity while maximizing materials and maintaining ease of use.

Radan 2015 now creates more compact nests than ever before by spreading parts more evenly throughout the sheet, and by better utilizing the middle of the sheet to fully utilize materials. Additional nesting upgrades include the automatic application of rectangular nesting when appropriate for nearly-rectangular parts, a time-saving enhancement that helps in maximizing the sheet.

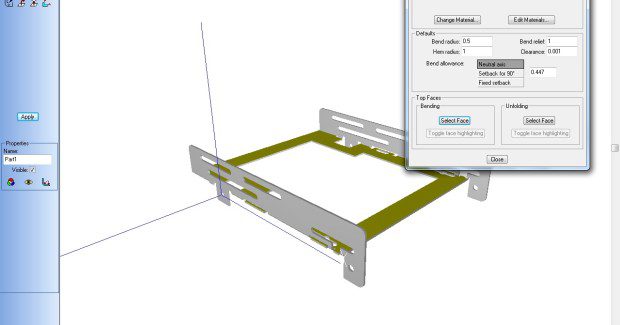

The software also offers improved 3D translation procedures that ensure information is imported more consistently. Its ability to automatically calculate the thicknesses of imported parts has been redesigned to yield faster and more accurate results. An upgrade to automatic face selection enables the feature to now be applied to unfolding. It also allows users to manually specify the top face much earlier in the programming process. This functionality is particularly important for Radbend, as it ensures that the visible face of a part remains scratch-free.

A number of important machine automation functions include significant enhancements to part removal. The amount of validation each Pick instruction requires has been increased. Key part suction cups can be defined on the picker and data introduced to the machine definition file, defining key part suction cups that must be turned on and be positioned over the metal when picking.

Acknowledged as one of the world’s leading PC-based CAD/CAM solutions for the sheet-metal industry, Radan offers a unique combination of applications for punching, profiling, bending, nesting, designing, and production management.

Vero Software, Hadley House Bayshill Road, Cheltenham, England GL50 3AW, +44 (0) 1189-756084, www.verosoftware.com.