Orbital Welding: A New Kid in Town

For 25 years the M207 from Arc Machines has been the workhorse system of choice for leading mechanical contractors. But it now appears the M217WDR will likely be its worthy successor.

Posted: December 3, 2014

Arc Machines, Inc. (AMI; Pacoima, CA) has long been a market leader in the field of orbital welding. Beginning with the Model 107 fusion tube welder in 1979, and the Model 207 in 1989, the company set the industry standard for reliable commercial orbital fusion welding systems for over 30 years. Because of their simple robust designs, ease of use, and ability to consistently deliver quality welds, AMI has owned the lion’s share of the orbital welding market.

Recently the company introduced its replacement for the Model 207 — the M217 WDR. They’re calling it “The New Workhorse of the Orbital Welding Industry” and provided it with many new features. The big questions are:

- Will the M217 really measure up to the reliability and quality of the M207?

- Do all the new ‘bells and whistles’ make the power supply more effective and easier to use?

As both a customer and a partner with AMI, Critical Systems, Inc. (CSI; Shrewsbury, PA) has a fleet of AMI equipment for our leasing division and is their only outside authorized repair center in the U.S. We have worked with AMI from the design phase through the beta testing of the M217 over the past 18 months, and have purchased and performed in- house testing on a significant number of these units. The purpose of this article is to provide some straightforward information and share our perspective on this new power supply. Note: Arc Machines did not ask Critical Systems to write this article, however they have provided some information as requested.

ENGINEERING AND DESIGN

The first thing a new user will notice about the M217 is how similar it appears to the M207. The familiar ‘red box’ has the same foot-print to match up with existing coolers, and the lid and case close together with the splash resistant seal. The M217 is 13 pounds lighter, with a textured finish that resists stains and fingerprints. Connections remain the same to match up with existing weld heads and accessories, although they have been moved around to better facilitate spacing.

Opening the lid reveals the first major difference of the M217. In place of the failure prone membrane switches and often cryptic dual-line display windows, is a 12.0” high- resolution color touch screen (Figure 1). To its right are two USB ports, with a new thermal printer to the left. Another smart design feature: AMI eliminated the openings on the top surface of the M207 that allowed small items (tungsten electrodes, for example) to fall into the printer or CPU section.

Opening up the case is a simple task, with a shouldered socket-cap screw at each corner. Once removed, the upper section folds back, revealing the computer section in the top, and the majority of the electronics in the lower case (Figure 2).

With a lease fleet of over 160 AMI power supplies, and having repaired hundreds of customer systems as an AMI certified repair shop, we know what has a tendency to break, and how difficult and costly these repairs can be. With that mindset, we examined the guts of the M217 to determine if it truly will replace the M207. Here is what we found:

- The component layout appears to be very serviceable. All components are easily accessible, without the need to remove non-affected parts. Diagnosis and replacement, should a failure occur, is going to be a much simpler task than with the M207.

- As Figure 3 shows, all the sub- systems are arranged horizontally and firmly mounted to metal plates and brackets. This allows for complete airflow and prevents heat from building up. In addition, the primary heat load, the main power unit, is shielded from the rest of the system, and cooled by a pair of high volume fans in a push-pull arrangement. While noticeably louder than the cooling in the M207, this design should keep heat (the root cause of most electronics failures) to a minimum.

- The M217 contains far fewer individual connections than the M207, resulting in less potential failure All major sub-systems are wired with robust industry standard connectors. Fewer pass- thru style interconnects, board to board headers, or wire screw clamps, can only improve reliability.

- The power unit is designed exclusively for the M217 by AMI and manufactured to their specifications in the U.S. Its design criteria matches the M207 in most categories, and exceed it in one. While both are capable of 5-150A of welding power, only the M217 is capable of auto-switching between line voltages of 110V and 220V. Both units are 100 percent duty cycle rated. Why is this important? A power system that is 100 percent rated means that it was designed and specified for full power usage, and is not being pushed beyond its limits when operated there.

- Another area where the M217 improves upon the M207 is the DC voltage supplies (Figure 4). Based on our experience, the most common system failure in the M207 is the Low Voltage P/S. For the M217, AMI has chosen a quality third party supplier who has engineered and manufactured power supplies completely in the U.S. for almost 30 years. The units included in the M217 have an MTBF rating of 100,000 hours. Fully certified, including UL and CE, they are also qualified for use in the medical industry.

- Also notable, and we believe a first of its kind for welding systems, is the M217 controller/interface. The combined touch-panel/PC is NEMA IP65 rated against moisture and dust, and designed for use in rugged and demanding The elimination of the mechanical key pads used in the M207 can only improve reliability. Containing an Intel®processor and running embedded Windows 7®, the M217 controller should be a stable platform for the long run.

THE M217 IN USE

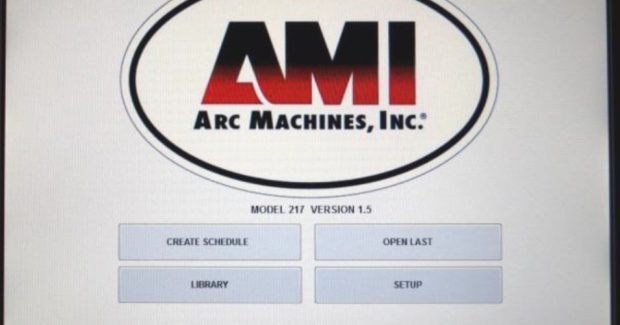

Hooking up the M217 is simple. Facility requirements are the same as the M207, except the fittings for the purge gas lines are compression style, instead of flared. The unit is switched on with its main breaker, in the same location as the M207. Power-up takes about 50 seconds, and displays the M217 home screen when complete (Figure 5).

The look is all business, with buttons for the four main functions in the center. Navigating through the various screens and operations is very intuitive, and after some initial assistance from the owner’s manual, anyone experienced with the M207 will have no trouble operating the M217.

One function worth mentioning here is the M217’s auto-generated recipe capability. The user enters four parameters (tube diameter, wall thickness, tube material, and the model of weld head) and the M217 pulls all the remaining schedule specifics from an on-board library containing AMI’s best practices. Select the type of weld you want to perform from the four choices (Auto-pulsed, Auto-step, Auto-tack, and S³) and the M217 creates and loads the new recipe — a far cry from the labor intensive and error prone process of the M207. Should a user wish to customize specifics or fine tune a weld, simply touching the schedule field relating to a particular parameter brings up a menu, and allows on-the-fly editing.

Another clearly observable improvement over the M207 is in how smoothly the M217 runs the various weld head motors. During all CSI’s testing, rotor operation was quieter, smoother, and homing more accurate. The M217 also performs a two-step speed calibration that checks both the low and high speeds of the weld head. We suspected this would contribute to a more precise speed control. As a test, using auto-generated recipe times and the M217 speed calibration, we ran a number of different cycles against a stop watch. All times were correct, as closely as could be visually confirmed.

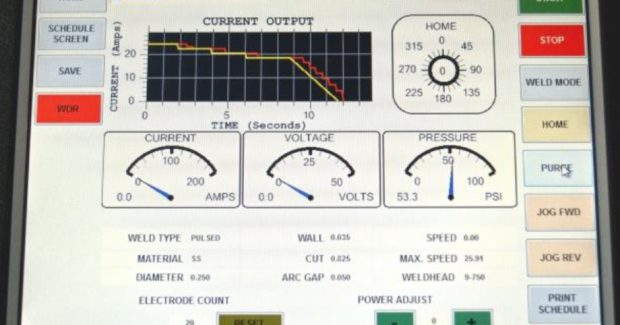

Operations are performed from the Weld screen (Figure 6). Individual displays provide constant feedback as the weld is occurring. Monitoring of the actual tungsten position as the rotor turns, the output current versus programmed current, weld step countdowns, purge pressure for both lines, and more, are all viewable in easy-to-read, real-time from this screen.

There were a couple areas that did not work as expected. One of the new features of the M217 is the capability to operate other manufacturer’s weld heads. To test this, we connected up an older model Swagelok 5H fusion head. While the M217 could jog the rotor in both directions, it failed to successfully run speed calibrations and homing operations. In addition, on its current model line-up Swagelok has changed the motor cable connector, and the connector on the M217 does not match. An adapter will need to be sourced for this mixed tool application.

The second issue occurred while testing the Weld Data Recording functionality. Several errors prevented correct operation and data retention and retrieval was ‘hit or miss.’

Note: Regarding these issues, AMI has informed us that the newest software release (Version 1.51) has addressed the speed calibration/homing issues on Swagelok heads, and the WDR functionality issue. Our follow-on review indicates these indeed are very likely resolved. We will pursue in-depth testing related to them in the near future.

Regardless, neither of these issues prevented the M217 from performing all normal operations. In fact, the quick resolution of these issues was further confirmation of the company’s commitment to addressing concerns as they surfaced.

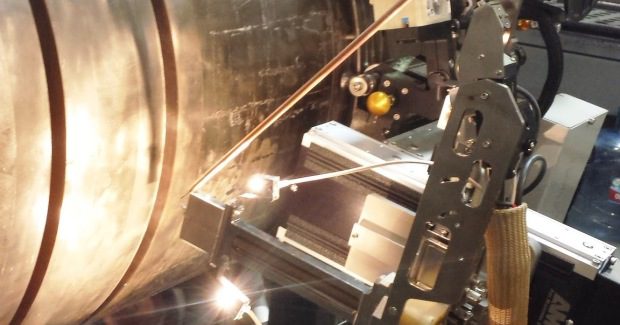

WELDING

So how does the M217 weld? Using a variety of AMI heads, from the 9-500 to the 9-7500, as well as the 8-2000 and 8-4000, we made welds on SS tube diameters from 0.25 in to 6.0 in, and wall thickness from 0.035 in to 0.120 in. Using the M217 auto-generated four level weld schedules, results were mostly excellent, with a few examples benefiting from small primary amp adjustments to the library values. Bead uniformity, fish-scale, penetration, and color were as good as the best we had ever seen from a M207, and often better.

Another advanced feature examined during weld testing was the capability to perform Single Slope Single Pass (S³) welds. S³ welding is a more precise type of weld than the current industry standard four-level fusion welds. The four-level weld schedule lowers the weld current every 90 deg of rotation in an attempt to keep the heat in the work piece constant.

But the heat buildup actually occurs in a linear fashion, not in steps, and can result in what is called the ‘Christmas tree effect’ as the weld bead narrows and widens. By reducing the weld current in a linear fashion designed to match the heat build-up, S³ welds should be extremely consistent from start to finish. Test coupons using this type of schedule on the M217 looked even better than the four level ones, and might easily become the industry standard as more organizations become familiar with this technique.

FINE TUNING THE M217

In addition to our in-house testing, we provided M217s to some external customers, requesting any and all feedback. The majority of feedback was positive, however, there were some minor requests related to features and usability comparisons to the M207.

Small adjustments to the user interface, added content and form of weld print-outs, durability of painted surfaces, and other enhancements were noted. This feedback, along with ours, was passed along to the company. Their response to these ‘market’ requests was positive and effective, which will serve them well as they continue to refine the M217.

SUMMARY

For 25 years the M207 has been the system of choice for many of the world’s leading mechanicals. Its robust design, ease of use, and long legacy all contribute to its place when looking for a professional grade orbital fusion power supply. But technology has not stood still, nor have the requirements for equipment that can provide high quality results while meeting today’s challenging project timelines.

Based on the results we have experienced, as well as feedback from some of the world’s most demanding mechanical contracting and engineering companies, the M217WDR will likely be that worthy successor.

John Throngard is the Senior Technology Specialist for Critical Systems, Inc. and author of this article. He can be reached at [email protected] or 866-229- 2291.

This article was first published on the Critical Systems website found in the Orbital Welding Products & Services section.