Step-by-Step Improvements: Understanding the Value of Advanced Welding Information Management Systems

To achieve big cost savings, quality improvements and productivity enhancements, advanced data management systems can manage and control almost any factor – before, during and after the actual welding process.

Posted: November 5, 2014

Editor’s Note: This is the second article of a two-part series by Caleb Krisher. The first article on basic welding information systems, “Capturing Real Welding Information to Drive Real Improvements,” was featured in the February issue of F&M Magazine.

Efficiency and accuracy in the welding operation are key to profitability. The consequence of errors such as missed or defective welds can be high, especially if a shop fails to detect the problem before a part flows through final assembly. The rework of a part at this juncture in the process becomes time-consuming and costly, and can easily hinder productivity goals. The potential loss of business or the safety risks of a poor-quality part reaching the customer is even more critical.

Advanced welding information management systems can help identify and rectify problems very early in the fabrication process. These systems provide complete control over the welding process, increasing both quality and productivity. Unlike basic welding information management systems that gauge high-level quality and productivity information, advanced welding information systems can manage and control almost any factor in the welding operation — before, during and after the actual welding process.

These data management systems connect via the Ethernet to capture real-time information for the entire fleet of equipment and store it in a central repository. This data drives change that helps welding operators, welding engineers, quality managers, plant management and owners alike. Benefits of these systems include:

- The ability to reduce missed and/or defective welds.

- Confirmation that welding operators are following the correct welding parameters (e.g., volts, amps, wire feed speed, gas flow, weld duration).

- Identification of over- and under-welding.

- Active weld sequence control.

- The ability to identify potential welding issues quickly, right in the weld cell.

- Augmentation of training efforts and shortened training time.

- Help in understanding the cost of fabricating a component.

- Understanding weld cell downtime (arc-off time).

- Tracking of part production.

- Workflow management (non-welding work instructions).

Advanced welding information management systems can also help identify maintenance needs so companies can proactively care for their equipment fleet. The combined result of these capabilities is better quality and productivity, and a more consistent approach to cost management.

Advanced welding systems can be implemented in either semi-automatic or robotic weld cells. Advanced welding information management systems are available factory-installed in a power source or can be retrofitted with upgrade modules to help companies leverage their investment in current equipment.

WELD SEQUENCE AND PARAMETER CONTROL

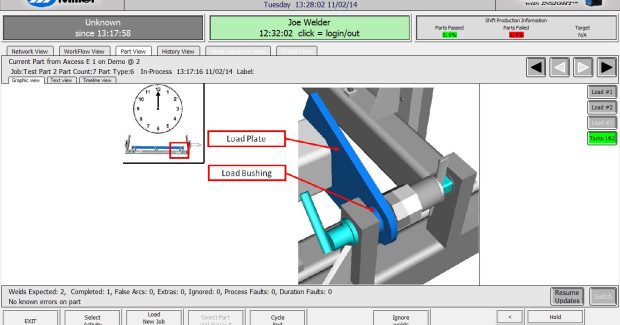

Welding operators interact with the system through a human-machine interface (HMI) located in the weld cell. The HMI (often a PC-based computer monitor) visually walks the welding operator through the correct weld sequence, providing step-by step cues along the way. Companies can use this sequence control to help minimize distortion on parts prone to this type of defect. Also, by counting welds and monitoring individual weld duration, it is possible to reduce the risk of missed welds.

While guiding the welding operator, the system also monitors the welding output to make sure the results fall within acceptable limits. Advanced systems can indicate amperage and voltage, gas flow, wire feed speed, and weld duration. The HMI alerts the welding operator if any of these factors fall out of tolerance, making it easy to identify areas for inspection and correction.

The most advanced systems are capable of providing cues that include non-welding work instructions such as how to load parts into the fixture, non-welding task reminders and even pack out instructions. Furthermore, advanced welding information systems can be programmed to respond in a number of ways when a welding operator welds outside of the preset parameter thresholds. At a minimum, the system can simply record anomalies for later review. The system can also alert the welding operator or supervisor to the fault or, in critical situations, the system can lock down entirely (via a set program) until the proper personnel identify and address the root problem. Individual programming determines the desired action.

TRACKING AND TRACEABILITY

These data management systems provide insight into activities throughout the weld cell. Parts can be tracked according to whether they passed quality control or failed, and the reason why. This allows for immediate quality control and quick correction of errors. The system can also flag nonconforming welds by part that, again, trigger alerts to management to drive continuous improvement activities.

It is also possible to track part production during a given time period, recording parts by shift and welding operator. This tracking helps to determine fabrication cycle times and the quality of parts created during a given period of time. Ad-hoc reporting allows cell-to-cell comparisons that can identify areas for improvement throughout the welding operation. The system documents every weld on every part, including the name of the welding operator who completed the weld; the average current, voltage and wire feed speed; gas flow; weld duration; deposition rate and amount; heat input; and whether the weld passed/failed. And all of these criteria feature a date/time stamp.

Welding-related costs, including the amount of labor, wire, gas and electricity used to fabricate a component, can all be tracked. If there is a disruption in Ethernet service, onboard buffering will continue collecting data and automatically push it to the system once the connection becomes available again. Even if there is a disruption to Ethernet service, the operator is free to continue fabricating components and using the HMI.

TRACKING NON-WELDING ACTIVITIES

For many welding operations, delivering 15 percent arc-on time is not unusual. The remaining 85 percent of a welding operator’s time is spent on non-welding activities. Shops that understand how critical non-welding time is to streamlining their fabrication process can use advanced welding information management systems to account for:

- Time spent waiting for components.

- Time used for pre- and post-weld activities like cleaning, grinding, scraping, and/or adjusting for distortion or similar defects.

- Employee breaks on a shift-by-shift or daily basis.

- Time spent on maintenance activities.

- Time spent on training.

Tracking this information facilitates the analysis of production bottlenecks and helps assess non-value-added activities that hinder throughput. The more sophisticated welding information management systems can even govern non-welding activities. For example, they allow the embedding of videos, documents, audio files, and more into the HMI. These assets show welding operators how to load fixtures, provide important fabrication reminders, offer instructions on how to pack out completed weldments and more.

IDENTIFYING AND IMPLEMENTING TRAINING OPPORTUNITIES

Many shops must hire welders with little to no experience due to the current shortage of skilled labor that is available. Advanced welding information management systems help facilitate operator training by serving as a virtual on-the-job trainer, using the HMI to identify different components and explain how and when the welding operator should weld them. This step-by-step process helps new operators learn the fabrication and welding process faster so they can contribute to productivity sooner.

Advanced welding information management systems also identify areas for continuous improvement initiatives for new and seasoned welding operators alike.

REPORTING AND APPLYING RESULTS IN REAL TIME

Advanced welding information management systems contain powerful reporting tools that make it easy to format data in the way management wants to see and use it. This data, in turn, helps achieve five key goals for continuous improvement:

- Prevent slowdowns in production for costly fixes.

- Empower companies to generate shorter cycle times per shift.

- Help ensure a solid return on equipment investments.

- Allow companies to produce a better, more consistent product.

- Lower costs through better manufacturing processes.

This software provides process, production and management reports and charts. It mines data from the system to provide weld, part, and cost and productivity analysis charting, as well as charts to track productivity. The data appears in summary form, allowing management and owners to establish a baseline for improvements and garner a high- level snapshot of the welding operation as time goes on. This reporting allows for the assessment of current trends and helps measure the shop’s continuous improvement efforts.

The reporting tools can facilitate cell-to-cell comparisons of most any variable in the welding operation, including activities from different welding devices and groups. This feature helps isolate points of differentiation in order to identify best practices and areas for improvement.

THE BOTTOM LINE

The benefits of an advanced welding information management system are significant, but they require a commitment on the part of management and owners. These systems are more complex in their usage than basic welding information management systems. The cost savings, quality improvements and productivity enhancements they provide, however, make it easy to justify the time commitment.

The key is to set up a clear implementation plan with objectives and milestones that will ensure that all intended benefits materialize. It is also important to identify an individual who has overall responsibility for implementing and managing the system. In some cases, a combination of basic and advanced welding information management systems may be the most beneficial for a company, which should consult with a trusted welding distributor and/or welding information management system manufacturer to assess their needs and implement the most effective course of action.