A New Look at Stainless Steel Machining

Canyon Hydro sped up deliveries by two months – without raising machining costs – with a last minute processing switch and a new multipurpose mill that roughs out 4,500 lb of chips in one-third the time of conventional face mills.

Posted: November 7, 2014

Sometimes a fallback process can put you far enough ahead to warrant making it your new standard. Canyon Hydro (Sumas, WA) recently did exactly that after deciding to switch to billets from castings as machining feedstock for their smaller hydropower runners.

What made the difference were a last minute processing switch and a big new Quad F multipurpose mill from Ingersoll Cutting Tool Company (Rockford, IL) that dramatically sped up the roughing operations. About 4,500 lb of chips came off in one-third the time as with conventional face mills – and far faster than by the originally planned turning operation.

Runners, the heart of all hydropower machinery, are very sophisticated water wheels made of stainless steel. They may measure anywhere from 18 in to more than 11 ft across, weigh up to fifteen tons and spin at up to 1,000 rpm to generate electric power. Smaller runners are machined from solid; larger ones are fabrications. For hydrodynamic efficiency and dynamic balance in service, all finished runners must be accurate to 0.010 in with a 32µ finish.

The largest supplier of hydropower machinery west of the Mississippi River, Canyon Hydro produces these runners in a state-of-the-art plant that normally operates 16 hours a day, six days a week. In peak times, shifts expand to 24 hour days, five days a week. “The common denominator of our work is 4-6 axis long-reach contoured cavity machining on stainless steel,” says manufacturing manager Loren Sweitzer.

The basic machining challenge here is much like those found in cavity hogging on large plastic injection molds: first hog out huge volumes of stock and then follow with careful profiling, including occasional undercuts.

PLANNING, THEN IMPROVISING

Actually, the shop made two significant processing changes, one planned and the other not. For strategic reasons, the company plans to convert from castings to billets as feedstock for runners up to 70 in diameter that are machined in one piece. “Billets carry a much shorter delivery lead time than castings, are much more consistent dimensionally, and contain no sand inclusions that can suddenly rupture a cutting edge,” explains Sweitzer. “Total floor-to-floor time with a billet is about the same as with a casting, even though more stock must be removed. With billets, we should be able to simply fixture the piece, push the Start button and stand back.”

The first billet, for a 52 in runner with a rush delivery requirement, hit the floor in February 2014, a full eleven weeks sooner than castings could be delivered. The big disc measured 52 in diameter by 12¾ in thick and weighed 9,000 lb. About 4,000 lb of stock needed to come off in initial roughing operations, essentially a four-axis job.

Originally, shop manager Ken Neal planned to rough the symmetrical portions by turning and then transferring the piece to a five-axis mill for the remainder of the machining. The trouble was that the lathe that could turn such heavy workpieces was already tied up for weeks on other work, and the customer needed the runner sooner.

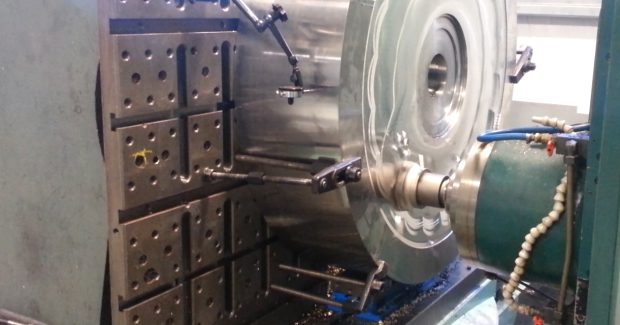

Enter Plan B, where Neal and lead man Jake Rawls moved the job to a six-axis Kuraki KBT 15BDX horizontal mill with a 44,000 lb turntable. This mill was tooled with Ingersoll 3 in Power Feed mills and 2 in Form Master ball mills on 15 in extensions. With their high feed geometry, both tools have become the shop’s mainstay for machining their larger fabricated runners, which are typically run on very large high-feed CNCs. However, the Kuraki emphasizes power and rigidity over table feed: it has a 35 hp spindle but a maximum feed rate of only 140 ipm. It is not a high-feed machine.

Quickly recognizing the spindle power available and the tonnage of metal to be hogged out, Rawls asked Chris Murray of Ingersoll for a 6 in version the Power Feed mill that had become a Canyon Hydro mainstay. Instead, Murray recommended the new 6 in Hi Quad F mill, reasoning that it would work better in such a high-torque, limited-feed situation. “Although it’s a high feed tool, the Hi Quad F has the geometry to take much deeper cuts where the feed rate is limited,” states Murray. “Moreover, its free cutting geometry and 12 deg lead angle reduce lateral cutting forces, for more stability in long reach milling.”

FOUR STEP ROUGHING SEQUENCE

In the first 24 hours of operation, a 6 in and a 4 in Hi Quad F face mill, each running on 5 in extensions, combined sequentially to remove about 3,500 lb of stock in continuous contact service. The former tool ran at 312 sfm, 120 ipm, 0.100 in DOC to peel off 50 cu ipm with a predictable 45 minute edge life in the cut. The latter tool ran at 442 sfm, 70 ipm, 0.100 in DOC with edges lasting 90 minutes in the cut. Edges were changed solely because of wear and surface finish, never for rupture.

The 2 in Power Feed, a very strong high feed face mill, followed to handle some of the asymmetrical portions and the interrupted cuts created in the first operation. Finally the 1.5 in Form Master, an advanced button mill, went in to complete deeper portions of the cavity – and some undercuts – on 15 in extensions. These are the areas most likely to create chatter. Nevertheless, Canyon Hydro ran it at higher than recommended parameters with no chatter whatsoever. “The higher feed rates actually helped stabilize the tool,” notes Rawls.

The Form Master button cutter works like a standard contour mill for most of the pass, then like a T-slotter for the undercut portions. To defeat harmonic vibration, it features asymmetric flutes and serrated round inserts in a “timed” array. Each insert is turned “five minutes” from the other, so each edge engages a different area of the cut and the whole toolpath is covered progressively with every full cutter revolution. “It’s essentially a progressive button mill with chipbreaker inserts,” says Murray.

“Given our workload and machine fleet comprising both high-power machines and high-feed machines, the Hi Quad F should prove a real asset,” adds Sweitzer. “It makes the most of both types of machines and also minimizes cutting forces to reduce runout and chatter.”

THE NEWCOMER: CLOSE-UP AND PERSONAL

Although Canyon has relied largely on Ingersoll tooling since opening its doors at this lights-out plant in 2009, the Hi Quad F is a newcomer. According to Murray, the key to the cutter’s effectiveness is the combination of high feed and deep-cut geometry in the same tool. With 19 mm inserts it can handle depths of cut up to 0.118 in. It also accommodates seven different styles of insert to address a wide variety of machining conditions and materials that the shop encounters. “I can see using the Quad F on our larger runners and runner buckets as well,” says Neal. “The big ones can involve months of continuous five-axis chipmaking on 28 in extensions.”

Summarizing the billet experiment, the feedstock and processing changes sped up deliveries by two months without raising machining costs. “The chipmaking ran very fast and free of interruptions so typical of machining castings, with inserts lasting 7 hours in the cut on average,” states Rawls. “With the tooling package we used, things worked out better than expected and far better than by starting with a turning operation.”

As a result, Canyon Hydro is working toward standardizing on billets as feedstock for runners up to 70 in, milling them with the same tooling package. “We’re feeling our way here,” explains Sweitzer, “but success on this 52 in runner certainly bodes well.”

“A lot of our work is one-off jobs on short lead times, so we don’t have time to run a full tool evaluation whenever a new need arises,” adds Neal. “In this case, we had a job on the floor that was running too slow and thought we simply needed a bigger version of a proven tool. The better idea came from Chris, right on the spot. We rely on such vendors because we don’t have time to research all of the tooling options when a new job hits the floor. We look for guys who solve problems quickly rather than selling hardware.”

Ingersoll Cutting Tools, 845 South Lyford Road, Rockford, IL 61108-2749, 815-387-6600, Fax : 815-387-6968, [email protected], www.ingersoll-imc.com.