Making a List, Checking It Twice

Returning your machine or a program to its original condition can now be as simple as saying “big data.”

Posted: November 5, 2014

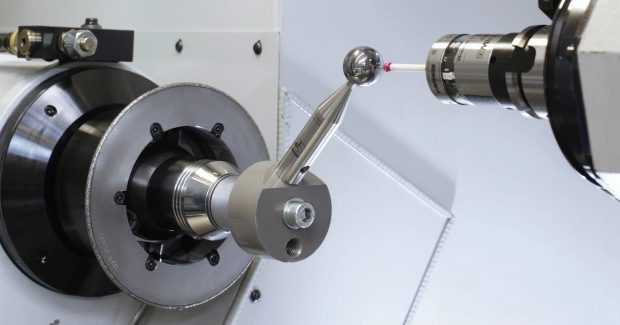

There’s an old “saw” in the construction business that says “measure twice, cut once,” and it’s true. The difference in our world of metalworking and fabrication is that the sophisticated CNC on your machining center, laser welder or waterjet not only gathers all of the information that’s being called “big data” these days, it’s also able to produce reports in a priority format – a feature that provides maintenance technicians and programmers with the ability to get your machine tools and programs running as commissioned or set up.

As the year ends with many shops busier than they can ever recall, here’s a friendly reminder to take the time to do your year-end maintenance so your shop is better prepared for the New Year’s rush. In the spirit of that guy in the red suit who got famous by making his list and checking it twice, here’s a list for machine shops, contract manufacturers and metal service centers to follow:

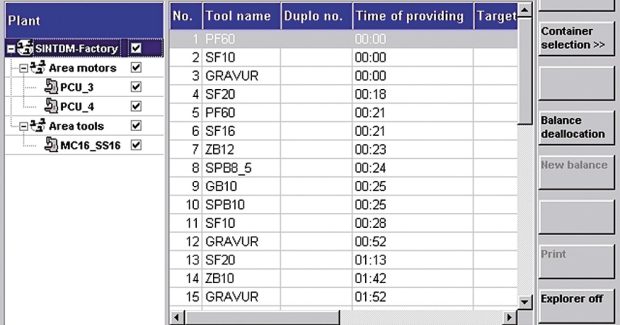

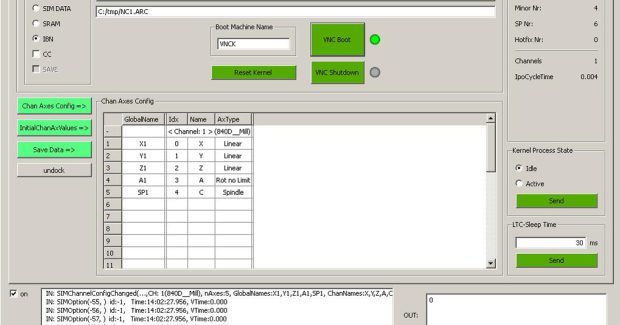

Do your back-ups and archiving. Check the offline storage devices used in your shops and correct the programs for parts in production as needed. If you use MT Connect in your shop for cross-floor communication, exploit it to its fullest extent. Most CNC models can accommodate this protocol, which allows your shop to compare machine-to-machine performance as well as the work on a particular program being done on various machines.

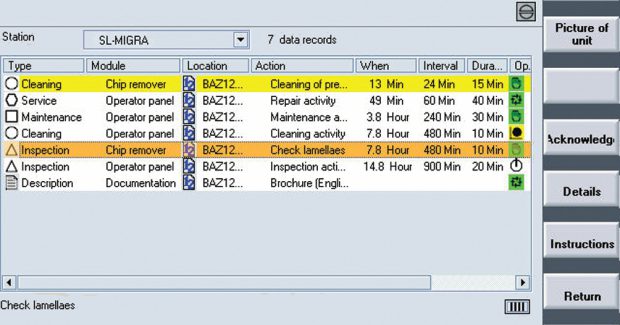

The term “big data” refers to something we all heard more often than any other concept in machining except additive manufacturing at the IMTS 2014 show a couple of months ago. In the CNC world, big data refers to the control’s ability to literally regenerate all of the information on a part or a machine component, going back to set up or commissioning. This may seem to be an overwhelming amount of knowledge for most shops, but the CNC now gives them the opportunity to prioritize all of this data into time-sensitive silos so they can track machine activity and part production by shift, by day, by month, etc., back to a known “perfect” reference point in time or production runs.

In other words, big data enables troubleshooting to become a proactive – not reactive – concept, meaning more action can be taken at an earlier point in the maintenance process of machine tools and programs to keep them all running more effectively.

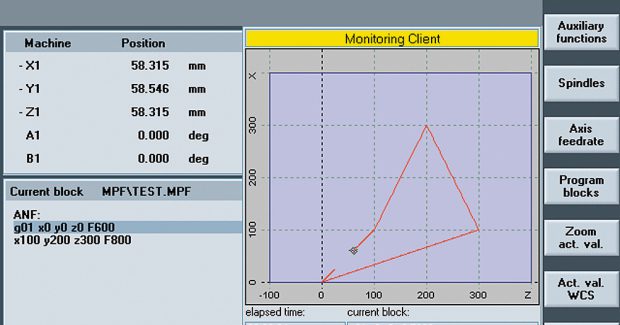

Doing this literally involves the push of a button. Typically, a combination of key touches can set up the recording of data, then you can have one hot key to recall all parameters in whatever format, priority and time frame you choose.

Remember, the practical goal of an archive is simply analogous to a restore point on a Windows PC. You can refresh the settings back to the original commissioning points for the motors, drives, spindle settings, etc. on the machine tool or do a quick, easy comparison between the setup points on a program and the actual run conditions of the machine tool at any point in time. A comprehensive client-server solution that enables secure archiving of all machine tool CNC data in an encrypted Internet communication is ideal and can usually be accomplished through your CNC supplier or an authorized third party source.

One caveat: Some things are never quite the same after they’re fixed, as anyone who’s ever had their car serviced can tell you. This holds true for machine tools as well. Resetting a machine tool to its original condition alone cannot compensate for every change that may have occurred, so be sure you literally check everything . . . twice.

As we close out the year, I want to sincerely wish everyone a safe, peaceful and joyous holiday season. Make spending time with your family and friends the most important item on your list, because, my friends, that’s the most critical condition we’ll ever monitor.