Laser, Waterjet, Plasma Cutting Systems

A yearend review of some of the current advances and application capabilities in each of these metal cutting technologies.

Posted: November 5, 2014

Steven Cranston of Alliance Automation said, “This robotic waterjet trimming cell features numerous design innovations that distinguish it from other robotic systems and promise to increase productivity, lower operating costs and improve worker safety. The system lowers operating costs by eliminating the need for complicated trimming dies. It is set up so that many different parts can be programmed to make a quick change of tools or products. Jobs also can be installed with multiple parts to maximize productivity. In addition, the innovative design of the coil package on the robots allows for a quick change. All coils are a standard design (for each specific robot model), factory wound, pre-coned and pre-threaded.”

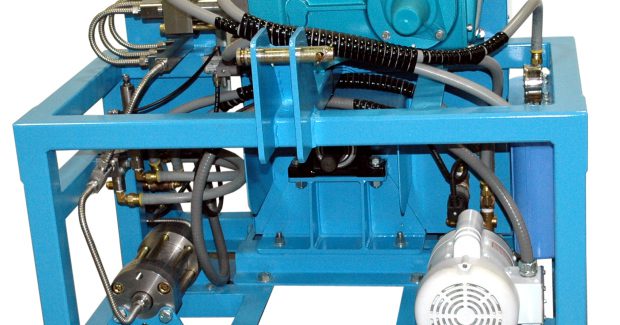

Established in 1984, Jet Edge is a global designer and manufacturer of waterjet systems for precision cutting, surface preparation and coating removal that are used around the world in a broad range of industries, from the world’s leading airlines to automotive, aerospace, industrial manufacturers, machine and job shops.

Jet Edge, Inc., 12070 43rd Street N.E., St. Michael, MN 55376-8427, 763-497-8700, [email protected], www.jetedge.com.

PLASMA CUTTING

COMPACT, AUTOMATED PLASMA AND OXY-FUEL CUTTING

ESAB Cutting Systems (Florence, SC) offers the compact SGX, an automated cutting machine for plasma and oxy-fuel cutting. The system is designed with leading-edge technology made affordable for the small fabricator or manufacturer. SGX is a rugged, high-performance machine that carries up to three tool stations, including up to two oxy-fuel torches and one plasma station that can be equipped with the m3-IGC Precision Plasma System for high-quality plasma cutting.

The compact design of the SGX cutting machine minimizes floor space requirements. One-meter rail increments keep the footprint small to maximize production space. Simple, automated operation is achieved with the built-in process database in the Vision T5 CNC, which fully integrates ESAB plasma and oxy-fuel process controls into an easy-to-use touch-screen interface.

The oxy-fuel gas control automatically switches between low preheat and high preheat pressure. Ease-on cutting oxygen allows for piercing of thicker materials. Gas controls are conveniently located at the side of the machine where the operator has easy access and can see the torches while making adjustments.

SGX can be configured with a wide range of plasma options, from simple air-plasma systems up to fully automatic 360 Amp multi-gas plasma systems. The machine can be equipped with m3 Plasma® for cutting up to 50 mm (2 in) thick mild steel. The m3 Plasma system achieves superior cutting results over a wide range of material types and thicknesses, and produces a high quality cut face with low dross, requiring little secondary clean up. It features an automatic gas control integrated with the process database on the CNC for fast and easy process setup without the guesswork.

SGX is available in sizes to cover plates up to 2,500 mm (8 ft) wide, and up to two 6,000 mm (20 ft) plates end-to-end. This cutting system is offered with a choice of downdraft tables or water tables for dry or under-water plasma cutting.

For more than 75 years, ESAB has been a total system supplier that offers off-the-shelf, turnkey CNC shape cutting machines in a variety of sizes, using a wide range of cutting technology to include plasma, oxy-fuel, laser, and waterjet tools, programming and nesting software, and CNC controls, to customers around the world.

ESAB Cutting Systems, PO Box 100545, 411 South Ebenezer Road, Florence, SC 29501, 843-664-5618, [email protected], www.esab-cutting.com.

ASSEMBLE YOUR OWN CNC PLASMA

The V Series Plasma from MultiCam Inc. (Dallas, TX) is designed for companies looking for maximum value in a CNC plasma machine. It is ideal for both entry-level as well as experienced manufacturers and anyone on a budget. The machine is now offered in an even more economical, easy-to-ship kit form. Easy-to-understand instructions are provided on DVD and the machines can be assembled and ready to operate in approximately 4-6 hours. EZ-G code and EZ-Suite application software is included with all machines to quickly convert drawings to machine code. And V-Series machine support and technical assistance is provided by a local MultiCam Technology Center to insure your investment.

MultiCam also offers the V-PRO CNC Plasma system that features a standard, heavy-duty, all-steel water table with integrated bladder capable of production processing of sheet steel up to 1.25 in thick without the need for fume evacuation. The CNC plasma system comes standard with a Hypertherm MAXPRO200 (200 amp) power supply engineered for heavy-duty, high capacity mechanized cutting. The V-PRO motion platform is isolated from heat built up in the cutting tank resulting in smooth, precise cutting of all material thicknesses. Automatic torch height is a standard feature and EZ-G code software is included for easy conversion of CAD drawings to machine-ready G-code.

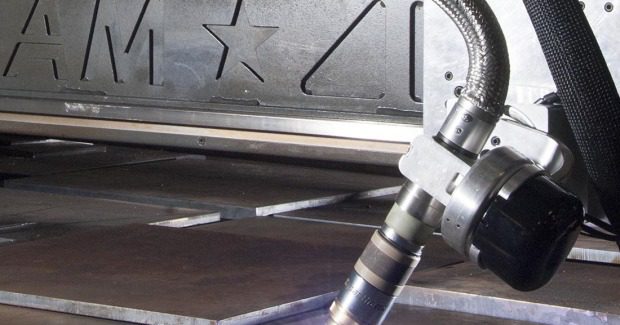

The company also offers a new 5-axis bevel plasma head for maximum performance that uses aluminum castings for weight reduction and rigidity. The new plasma head is not only a compact, durable cutting solution, but its innovative features provide for improved crash protection, as well as ease of maintenance. Its advanced technology provides for maximum table coverage which leads to a more flexible machine.

Although all MultiCam plasma machines have the capability to move simultaneously in the X, Y and Z axes, this new 5-axis bevel plasma head introduces two additional axes of movement, the “phi” and “theta.” These two axes allow operators to cut complex parts with bevels up to 45 deg in 2 in thick mild steel. The new 5-axis bevel plasma head was designed with the upgrade-ability of existing plasma systems in mind.

All bevel plasma systems come standard with Automatic torch height control (ATHC) along with EZ-G-Code 5-axis software for use with an existing 3-axis CAD/CAM system. In addition, all machines are fully compatible with SIGMANEST and Hypertherm ProNest 5-axis bevel CAD/CAM systems. MultiCam has over 70 Technology Centers worldwide that sell, service and support its products.

MultiCam Inc., 1025 W. Royal Lane, PO Box 612048, Dallas/DFW Airport, TX 75261, 972-929-4070, Fax: 972-929-4071, [email protected], www.multicam.com.

MANUAL CUTTING AND GOUGING FOR DEMANDING APPLICATIONS

Plasma arc gouging is a fast, economical, and environmentally friendly method of removing just about any metal: carbon steel, stainless steel, cast iron, aluminum, brass and bronze. Victor® Thermal Dynamics® (St. Louis, MO) has launched an improved PAK 200i manual plasma cutting and gouging system that has the capacity to satisfy the most demanding manual plasma application requirements. The system delivers 100 percent duty cycle at 200 amps, is capable of hand cutting up to 2¾ in (70 mm) on mild steel, as well as 10 ipm (254 mm/min) on 2 in (51 mm) carbon steel, and will remove up to 25 lb (11.3 kg) of carbon steel per hour.

“The PAK 200i is one of the most powerful manual cutting and gouging systems on the market today,” says Michelle Chamberlain, the brand manager. “It provides exceptional cost-performance benefits along with the same great reliability, simplicity, productivity and versatility of the PAK 200.” The PAK 200i now shares the same case and common platform with the company’s other 200 amp products.

Exclusive to the PAK 200i and particularly useful for gouging applications is the Tip Saver Plus feature. With accidental tip-to-work piece contact, the current will fold back to 35 Amps to ensure that the tip is not damaged, dramatically extending tip life. Other features include dual gas capability for superior cut quality and control on stainless steel and aluminum. The system, with a standard 2-year parts and labor warranty, can be configured to operate at 380-415V, 480V or 400V CE (European and Asian operation).

The PAK 200i system comes standard with the PCH 200 handheld torch, featuring a 70 deg or 90 deg torch head angle. The company also offers a 180 deg torch for mechanized applications, such as pipe beveling. Other applications include general fabrication, over the road transport trailers, railroad maintenance, vessel manufacturing, pipe beveling and fabrication, petroleum refineries, foundries, chemical plants, mining operations and ship building. When compared to conventional air carbon arc gouging, plasma arc gouging with the PAK 200i offers superior removal rates and clear visibility of the gouging area.

Victor Technologies, 16052 Swingley Ridge Road, Suite 300, St. Louis, MO 63017, 636-728-3000, victortechnologies.com.