Laser, Waterjet, Plasma Cutting Systems

A yearend review of some of the current advances and application capabilities in each of these metal cutting technologies.

Posted: November 5, 2014

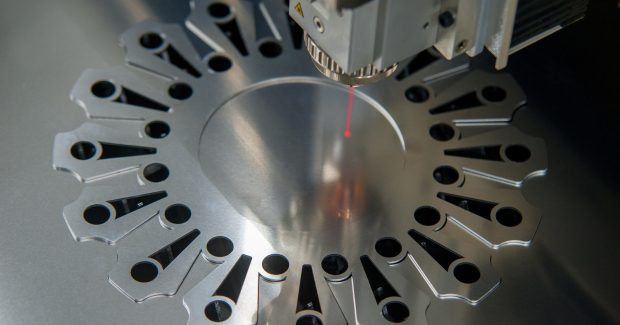

LASER CUTTING

HIGH SPEED, HIGH POWER FIBER LASER CUTTERS

Well known for its expertise in laser and nitrogen generation technology, MSS Lasers Ltd. (Rugby Warwickshire, UK) has expanded its fiber laser cutting capabilities with the Eagle eVision and iNspire range of fiber laser machines, sharing its knowledge and experience in a close partnership with the manufacturer. These machines are some of the most advanced in the market, giving users linear drives on all three axes and a low inertia carbon fiber transverse bridge construction that enables the Eagle to accelerate at up to 6G and achieve cutting speeds in excess of 100 m/min.

To make the most of the high cutting speeds, table change times are less than 10 seconds, minimizing idle time between sheets. This combination of rapid cutting and fast changeover makes the Eagle range of fiber laser cutters some of the most productive and profitable for users. For maximum versatility, customers can choose from different laser power options from 2 kW up to a maximum of 6 kW, which makes it one of the highest power fiber lasers currently available on a commercial machine and ideal for the fast cutting of thick material.

Accuracy is assured through the rigidity of the carbon fiber bridge and the dynamic polymer concrete frame which minimizes vibration and heat related deflection of the machine geometry. The Eagle range comes in bed sizes up to 6 m x 2.5 m, enabling it to cut the largest sheets. This extra bed size allows companies to cut very large parts and also benefit from more efficient nesting, increasing material utilization rates.

The design of the fiber laser eliminates the use of CO2 gas and many of the components such as the turbine, mirrors and bellows necessary on a CO2 machine, greatly reducing maintenance requirements and the overall footprint of the machine. Power consumption is also around 70 percent less than a CO2 machine enabling customers to make dramatic savings, especially valuable with increasing energy costs.

Further advantages include rapid start up and shutdown of the machine, minimizing delays at the start of a shift, and the ability to cut reflective materials such as copper and brass and also plastic coated materials, thanks to the frequency range of the fiber laser.

MSS Lasers is a privately owned pioneer in the supply of high pressure nitrogen generation plants for laser cutting. Not only does this save users the cost of purchasing gas, but it also has environmental and operational benefits by providing nitrogen on demand at the customer’s premises.

The company was formed in 2003 by managing director Carlos Gonzalez-Lee, whose research and experience in laser cutting, along with the need for an independent specialist laser company in the UK, provided the springboard for the company’s growth in its core business of servicing and sales of all types of refurbished laser cutting machines and, now, the supply of Eagle fiber laser cutting machines. The company has developed partnerships across Europe, especially in Spain, where it is also distributing the Eagle machines.

MSS Lasers Ltd., Units 9-12, Allerton Road, Central Park Rugby, CV23 0PA United Kingdom, 01 788 5522 99, Fax: 01 788 5533 03, [email protected], www.mss-lasers.com.

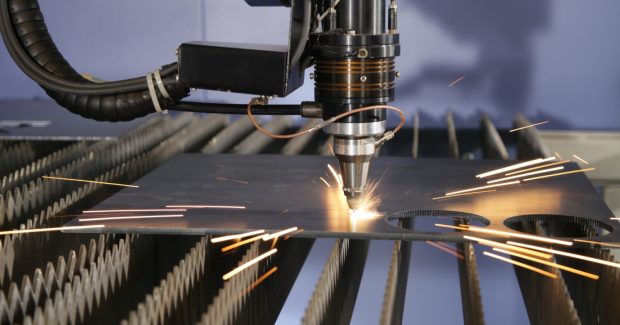

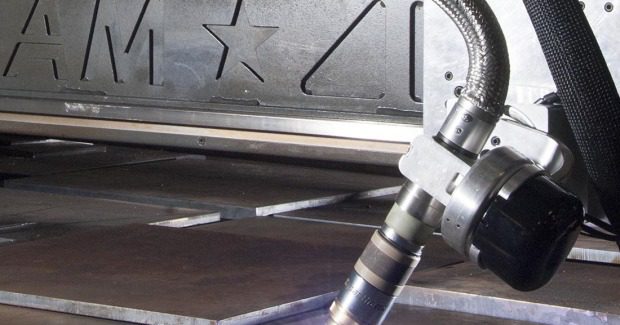

AUTOMATED LASER CUTTING OF PLATES

Mazak Optonics Corporation (Elgin, IL) offers the new SUPER TURBO-X laser-cutting system featuring the new Preview 3 control. It is the ideal solution for plate applications, especially where material automation is a consideration. The SUPER TURBO-X is built on the industry’s most reliable laser platform, with a rugged hybrid design and an easy access table. It features a proprietary vibration dampening frame and integrated laser resonator that ensure stable, high accuracy cutting. The constant beam length construction provides uniform cutting performance across the machine table.

The Preview 3 control greatly improves the machine’s operation efficiency by automatically determining the ideal processing conditions for each material type and thickness. It offers smooth, high-speed responsiveness and optimum acceleration and deceleration to reduce cutting times. It also features a user-friendly 15 in touch screen with a high-quality display to view 3D cutting path graphics.

The machine’s new Opti-Pod offers automated setup features that help minimize preparation time and improve extended unattended operation. These are intelligent functions designed to both automate and help maintain optimized machining conditions for increased productivity. SUPER TURBO-X series machines are available in 2.5 kW and 4.0 kW CO2 configurations, with table size options of 2412 (49.21 in x 98.43 in), 3015 (60.04 in x 120.08 in) and 4020 (78.74 in x 157.48 in).

Mazak Optonics is a major supplier of laser-cutting systems, offering 50 laser models and leading the industry in the implementation of emerging laser technologies from its 50,000 sq ft North American headquarters in Elgin, where a 30,000 sq ft laser technology center houses up to 18 machines for demonstrations and training.

The company is part of Yamazaki Mazak Corporation (Oguchi, Japan), the global leader for the manufacture of machine tools and systems for the precision machining of metal parts, including CNC turning centers, horizontal and vertical machining centers, Multi-Tasking machining centers, turnkey cells and software solutions. The North American headquarters for Yamazaki Mazak are located in Florence, KY.

Mazak Optonics Corporation, 2725 Galvin Court, Elgin, IL 60124, 847-252-4500, [email protected], www.mazakoptonics.com.

LARGE-FORMAT 2D LASER CUTTING

Built especially to handle oversized formats, the TruLaser 8000 laser from TRUMPF Inc. (Farmington, CT) cuts sheet metal up to 52 ft long. The machine is the ideal solution for companies processing very large parts or for job shops looking to expand their capacities and range of services. The customer has the option to choose between two pallet concepts and six format sizes, ranging from 8 ft x 20 ft to 8 ft x 52 ft.

http://youtu.be/CAK8DL9dlt8

This newly designed 2D laser cutting machine offers many innovative features, including the optional AdjustLine function that modifies the cutting process using specially developed cutting tables to increase the tolerance for variations in material quality. The optional CoolLine function uses water to remove excess heat created while cutting to achieve far superior cutting results when dealing with low-grade material.

This large-format machine also grants a 0.2 in increase in the maximum thickness for mild steel and stainless steel. Fabricators are now able to process this material, up to one inch, using a 6 kW laser. The single cutting head strategy makes it possible to cut all material thicknesses without changing out the head.

With the new design, the machine’s control concept has also been enhanced. The user interface has been significantly simplified, as the machine now features self-explanatory, dialog-based touch command. The ergonomic control panel can be adjusted for operator preferences and the lighting conditions in the production area.

A cabinet for the machine’s accessories is located directly below the control console, ensuring nozzles, lenses and cleaning sets are always at hand. The high-efficiency cooling unit increases energy utilization, as does the updated laser standby mode. When the TruLaser 8000 suspends cutting, the laser reduces the amount of power it draws by 40 percent, yet stands ready to resume cutting in just seconds. The LensLine feature automatically checks the condition of the focusing lens, increasing its service life and eliminating unnecessary cleaning cycles. Clearly marked maintenance points, easy access locations and clear maintenance instructions contribute to the speed and ease of service.

Also, as of the end of October 2014, standard machines in the TruLaser Series 5000 will be able to cut through stainless steel up to 2 in thick. And when fitted with the BrightLine option, 2D laser cutting machines can considerably improve the quality of the edge on stainless steel sheet at gauges between 0.8 in and 1 in thick. This is made possible with TruFlow 8000, a CO2 laser that delivers 8 kW of power, and a mirror cutting head. The higher laser output is especially designed for shops that work stainless steel and aluminum.

To make full use of the laser’s high output, TruLaser machines with the TruFlow 8000 are equipped with a mirror cutting head. Since the heat-related effects are less than with lenses, the mirror-based optical system is reliable even if a considerable amount of dust has collected. As a result, cleaning is required less frequently and the wear rate at the mirror is distinctly less.

An added benefit is found when the enhanced laser power is combined with the BrightLine function. This option uses a special mirror head with a foot-long focal length to produce clean and smooth edges, even in stainless steel up to 1 in thick. With its newly increased laser output, the machine is especially beneficial for companies processing a large quantity of thick-gauge stainless steel. Applications include making blanks for machining or cutting parts that could previously only be done with plasma or water jet equipment.

With the ability to cut stainless steel up to 2 in thick, the machine easily prepares blanks for subsequent machining operations. Instead of milling the part from bar material with a great deal of waste, the laser cuts the contour out of a plate of sheet metal, meaning several different shapes can be efficiently nested together to save material and machining time.

TRUMPF Inc., 111 Hyde Road, Farmington, CT 06032, 860-255-6104, Fax: 860-255-6424, [email protected], www.us.trumpf.com.