Mill, Drill, Grind Aerospace Parts on One Machine

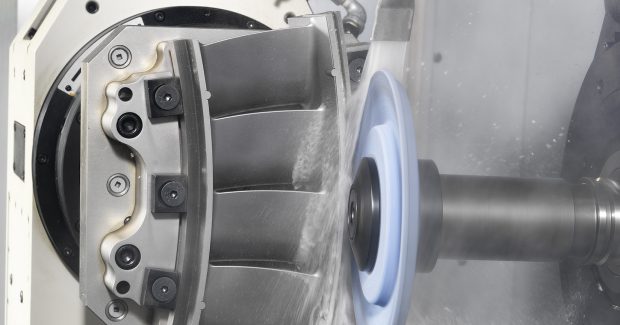

The flexible G7 Grinder 5-axis horizontal machining center from Makino grinds, drills and mills aerospace blades, vanes, turbine disks and other complex components.

Posted: October 30, 2014

The G7 Grinder 5-axis horizontal machining center from Makino, Inc. (Mason, OH) offers a flexible, single-platform solution for grinding, drilling and milling of aerospace blades, vanes, turbine disks and other complex grinding applications. Its multifunctional configuration, paired with 5-axis capabilities, enables aerospace manufacturers to eliminate setups, work in process, stack-up errors, and fixture costs. It also simplifies the manufacturing process with NC-controlled intermittent dress.

“Today’s capital equipment must be more flexible and capable than ever, removing non-value-added time from the manufacturing process,” said David Ward, the horizontal product line manager at Makino. “With the G7’s capability of combined milling and grinding operations, you’re not only saving on capital equipment, but you’re also eliminating multiple set-up operations and work in progress times that add to your costs and lead-time.”

Similar to the G5 5-axis horizontal machining center, the G7 employs a 12,000 rpm HSK-63A spindle capable of handling tough-to-cut materials, such as inconel. The machine provides X-, Y- and Z-axis travels of 690 mm by 650 mm by 730 mm, respectively, accommodating workpieces with a maximum diameter of 535 mm. This ability enables machining of parts one size larger than the G5, such as super-heat-resistant jet engine parts, curvic couplings and vanes (NGV). Its infinite C-axis rotation and maximum B-axis rotation of 270 deg offer full access to three-dimensional parts for single-setup production capabilities.

A unique two-axis Programmable Coolant Nozzle (PCN) lets the G7 accommodate variations in wheel diameter and changes in cutting direction while maintaining ideal coolant flushing conditions. It also allows for intermittent rotary dressing, an NC-controlled, electrically powered feature that trues the wheel to reestablish profile geometry on the cutting wheel. Combined use with the standard 60-tool capacity automatic tool changer enables continuous operation to be performed, maximizing throughput.

A world leader in advanced CNC machining centers, Makino is committed to providing high-performance, leading-edge machining technologies and innovative engineered process solutions that enable manufacturers to focus on making what matters through a wide range of high-precision metal-cutting and EDM machinery, including horizontal machining centers, vertical machining centers, 5-axis machining centers, graphite machining centers, and wire and ram EDMs.

The company’s flexible automation solutions provide reduced labor costs and increased throughput in a variety of production volumes and designs. Makino’s engineering services offers industry-leading expertise for even the most challenging applications across all industries.