FABTECH 2014: Welding, Tube & Pipe Fabrication

Here are some reviews of the welding systems and tube and pipe fabrication machinery being exhibited at this year’s show.

Posted: October 9, 2014

ROBOTS FOR SPOT WELDING, MATERIAL HANDLING AND MACHINE TENDING

In Booth C-1510, the IRB 6700 robot family is the seventh generation of industry-leading, large industrial robots from ABB Inc./Robotics (Auburn Hills, MI). These are available in payloads from 150 kg to 300 kg, reach from 2.6 m to 3.2 m, and are designed for spot welding, material handling and machine tending. In addition to enhanced speed, payload and accuracy, the power consumption has been lowered by 15 percent, total cost of ownership has been reduced by up to 20 percent, and maintenance has been optimized, doubling the time between service intervals.

An overview and demonstration of the IRB 6700 robot family from ABB.

The new model is available with LeanID, a new Integrated Dressing (ID) designed for easier programming and a smaller footprint. It has also been built to withstand the harshest working environments and is available with the ultimate Foundry Plus 2 protection system. www.abb.com/robotics

NEW TORCHES FOR AUTOMATED PLASMA CUTTING SYSTEMS

In Booth C-2962, American Torch Tip Inc. (ATTC®; Bradenton, FL) launches the new PHDX Series of torches for automated plasma cutting systems up to 260 Amp. The PHDX torch is designed to keep consumables cooler through superior heat dissipation. Cooler-running consumables last longer, reducing the number of change-outs needed, increasing the number of parts cut, and improving your productivity. Test results show PHDX torches and consumables result in a clean cut profile, negligible unintended bevel and easily removable dross.

Conversion kits make replacing your current high-amp plasma torch quick and easy. For peace of mind, we offer our 100 percent Guarantee Trial Program, Lifetime Warranty on the torch (the best torch warranty in the industry) and technical support by ATTC plasma specialists who know your equipment. Visitors are encouraged to ask about this program to be confident their tests results will prove the long-term value of PHDX plasma torches. www.ATTCplasma.com

OXYGEN MONITOR EXPEDITES PURGING IN HIGH PURITY WELDING

In Booth C-2118, the Aquasol Corporation (North Tonawanda, NY), an advanced and innovative manufacturer of water soluble consumables and other welding technologies, introduces its PRO OX®-100 programmable digital handheld oxygen monitor for fabrication shops.

Several advanced features help operators efficiently identify the ideal purge environment to create oxygen free welds, preventing discoloration and coking. The self-calibrating PRO OX-100 is equipped with an internal pump that draws a sample from the purge chamber and relays its oxygen resolution value to the monitor. This method serves as an alternative to hand aspirated pumps, which demand more physical exertion and time from the operator and yield less accurate results.

All units come with conversion software, which enables rapid capture and export of 50 data points to Microsoft Excel and plain text format. This means data can be easily transferred to the user’s PC using a USB interface. Data collected from the oxygen monitor can then be stored and to meet the strictest quality control requirements of nuclear and other highly regulated industries. The Quality Management System of Aquasol meets the requirements of the international standard ISO 9001:2008.

The PRO OX-100’s built in audiovisual alarm will sound and flash, when the targeted ppm is reached, allowing the operator to focus on other aspects of production until notified. With a presence in over 80 countries, the PRO OX-100 has built-in multi-language capabilities in four languages: English, German, Portuguese, and Spanish. www.aquasolwelding.com

TURNKEY SYSTEMS FOR MANUFACTURING PRECISION TUBE & PIPE

In Booth C-608, ASMAG USA, Inc. (Schaumburg, IL) and its parent, specialty machine and plant manufacturer ASMAG GmbH (Scharnstein, Austria), celebrate 30 years of building line machinery for drawing, straightening, saws and cutters, chamfering, stacking, and bundling. The new strategic focus is on delivering complete plants for the manufacture of precision steel tubes, pipes for OCTG, and copper and brass tubes, rods, and profiles.

These systems are built in dedicated manufacturing facilities in Austria and Germany using highly trained personnel. The company also owns SEUTHE GmbH (Hemer, Germany), which has 115 years of experience in the development of tube welding technology. Three tube welding plants with patented FCF (flexible cold forming) technology have recently been shipped from their facilities, ready to go into operation. The FCF and CTA (central tool adjustment) cage forming technologies developed by VAI SEUTHE mean substantial savings in time and thereby reductions of costs in the manufacture of tubes in a variety of dimensions. www.asmag.at

SEMI-AUTOMATIC AND AUTOMATIC WELDING GUNS

In Booth C-2944, Bernard (Beecher, IL) will display its semi-automatic MIG guns and consumables and Tregaskiss (Windsor, ON) will showcase its robotic MIG guns, consumables and peripherals. Notable products to be featured at the show include the Bernard Best of the Best (BTB) Platform Guns, a new product line that allows users to build their ultimate MIG gun by choosing from an expanded list of the best features from the former Bernard Q-Gun™, S-Gun™ and T-Gun™ MIG Guns. The top features from each legacy gun line have been consolidated into a single MIG gun offering with a single online configurator.

The newly redesigned Bernard Clean Air™ Fume Extraction Gun allows welding operators a more comfortable option for reducing harmful weld fume and smoke in their work area. With a small and lightweight design, this new Clean Air Fume Extraction Gun has nearly the same dimensions as a regular Bernard Semi-Automatic MIG Gun and is ideal for most medium- to heavy-duty solid or flux-cored wire welding applications.

Bernard, a division of Illinois Tool Works Inc. (ITW; Glenview, IL), manufactures premium semi-automatic GMAW (MIG) and FCAW (flux-cored) welding guns, consumables, accessories and manual arc products. For more than 60 years, the company has been an innovator in heavy-duty MIG welding and a contributor to improved welding productivity. BernardWelds.com

Tregaskiss will be proudly showcasing new robotic MIG guns designed to provide durable, repeatable and accurate welding performance for manufacturing and fabrication applications. It will be the first introduction of these products to the marketplace; visitors are encouraged to stop to see these show exclusives.

Tregaskiss, a wholly-owned subsidiary of ITW, is an industry leader in the development and manufacture of robotic MIG welding guns, peripherals and consumables, including TOUGH GUN™ Robotic MIG Guns and Peripherals, TOUGH LOCK™ Consumables, QUICK LOAD™ Liners, the QUICK LOAD Liner AutoLength™ System and TOUGH GARD™ Anti-Spatter Products. Tregaskiss.com

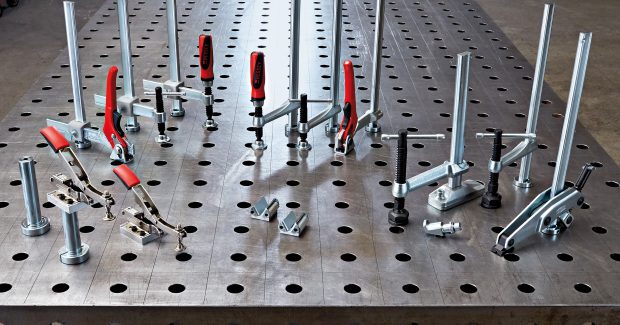

NEW WELDING TABLE CLAMPS

In Booth C-2622, BESSEY Tools North America (Cambridge, ON) announces a new family of high-quality welding table clamps designed for 28 mm matrix tables. There are a range of choices for different needs including variable throat depth versions and accessories to complement the clamps.