Breaking Down Automated Bending

Here are five basic areas to evaluate when considering whether it is right to invest in an automated bending solution, and if so, which type of system to choose.

Posted: October 9, 2014

Automation has become increasingly important in today’s manufacturing environment. At the press brake, a place where a bottleneck occurs for many fabricators, the challenges are numerous. As sheet metal cutting technologies continue to evolve and increase the speed of processing, press brakes are buried in stacks of flat parts. Meanwhile, forming operations are still limited by the speed of a human operator, combined with the need for safety and ergonomics.

The obvious answer is to add capacity, and that is what most manufacturers are choosing to do. However, this means increasing overhead in addition to the capital investment, as more labor is required to keep new press brakes productive. The alternative is to automate bending and achieve additional capacity, and higher productivity, without adding overhead. The problem here is that bending automation is something of a frontier for most companies, even for those with extensive experience automating other processes.

This complicated topic can be broken down into a few standard criteria that can be used to evaluate any automated bending technology to determine if it is a good fit for your production needs. When considering if it is right to invest in an automated bending solution, and which to choose, there are five basic areas to evaluate: blank loading, system automation, the press brake, part unloading, and programming.

Tom Bailey examines automated bending in greater detail.

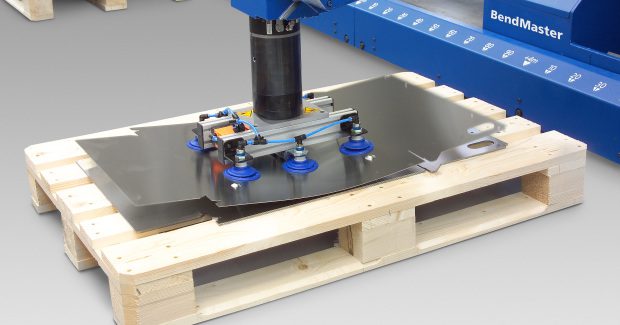

BLANK LOADING

The first component in automated bending is the method used to deliver flat parts to the robotic cell. This includes the delivery of raw material to the robot, as well as how that robot will locate and pick up the material. Traditional systems require parts to be perfectly stacked, squared and precisely located before they are loaded in the machine. Alternatively, the robot must take each individual blank to a squaring station to establish the correct orientation before bending. The latest machines now come equipped with a high speed vision system to identify the exact orientation of the blanks. Since they do not need to be perfectly stacked and can be taken directly from standard loading bins or pallets, this facilitates material flow through the production process.

AUTOMATION

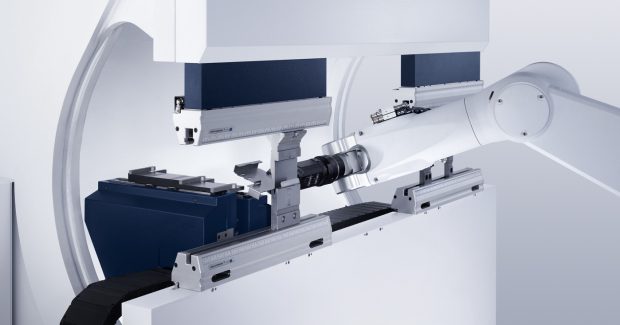

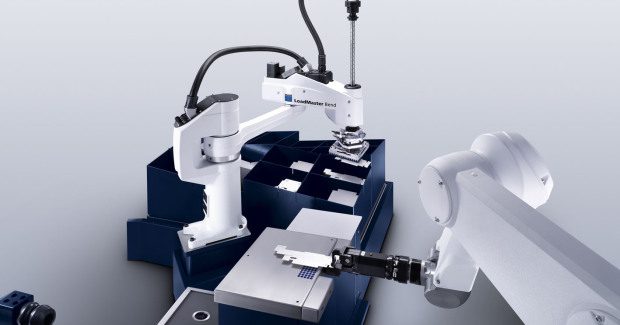

Take a close look at the robot when considering automated bending. First, it is necessary to determine whether a semi-integrated or a fully integrated system is the best fit for the needs of a shop. A semi-integrated option means taking a standardized, off-the-shelf robot and press brake and marrying them together, usually with the assistance of an integrator. A semi-integrated system will feature a lower initial investment cost, but since the robot has not been designed specifically for the task, it will be less efficient when processing parts.

Also remember that the press brake and the robot will not always be perfectly matched. A benefit of purchasing a fully integrated system from a single supplier is that its components have been designed to work together. Once it is in operation, this solution will naturally be more flexible and require less manpower and less intervention than a semi-integrated option. The best possible performance is achieved when the robot is purpose-built for the system. This very close synchronization between press brake and robot will achieve the highest level of productivity.

PRESS BRAKE

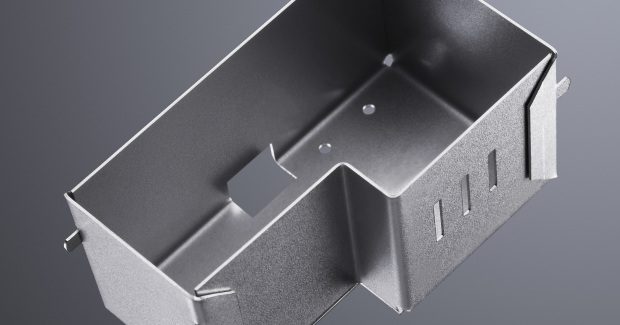

The press brake is fundamental to the bending operation. To determine the tonnage and bed length needed, establish what parts will run in the automated cell. A realistic understanding of the size and thickness of parts that will flow through the cell, and any recent business trends or developments will help dictate the best solution. These factors also define the space needed for the press brake and the entire system. As a general rule with machine technologies, gearing the equipment as closely as possible to a specific range of products (based on size or weight, for example) will yield the greatest efficiency in production. The larger the range of products a fabricator wishes to automate, the more compromises he or she must make.

For example, to bend everything from a bracket the size of a business card to a 5 ft x 10 ft sheet of material, one must select the press brake and robot accordingly. This means a larger, slower robot and press brake than is necessary for bending smaller parts. The flexibility is possible, but one must accept that space utilization and processing speed may not be ideal.

PART UNLOADING

For an automated bending cell to run profitably, the parts must be unloaded efficiently. First determine if the parts can be dropped or if they need to be placed down gently to protect their finish. It is also best to calculate how long the system will be able to run parts unattended to better understand labor costs and requirements. Also consider whether a conveyor or cart system is needed to move the finished product away from the bending cell. Establishing production requirements such as these will help define the required system capabilities and floor layout.

PROGRAMMING

Programming has a significant impact on the productivity of an automated bending cell as it increases or diminishes the overall flexibility of the system. Offline programming capabilities maximize the uptime of the machine by allowing fabricators to create new jobs parallel to production. With 3D simulation, programmers can check for problems, define tool setup, and program the press brake and robotic motions before running parts. The best systems will also enable manufacturers to give instructions for special part handling, and completely coordinate the press brake and the robot for highly fluid part processing.

Once the research is done, determine if the production requirements of the factory justify automated bending. Two avenues typically lead to a profitable return: labor cost reduction for the current operation, and gaining additional production capacity without adding labor.

For the most dynamic systems, there is a third possibility. The automated bending operation may also be faster than the current process, thereby creating gains in productivity. Any ROI calculation must take into account at least these basic factors: the investment cost of the automated system versus a stand-alone press brake; the labor cost with and without automation; the predicted uptime between the automated or manned process; and the cycle time of the production processes.

For this last point, it is very important to have a time estimate. This could be a rough number, such as a predicted time-per-bend for the automation and the manual process, or it could be a very specific number, for example, measured cycle time for a specific part or family of parts on the automated solution and on a stand-alone machine. With these factors in hand, it is possible to determine a true dollars and cents justification for investment in bending automation.