Keeping It Cool

Regardless of the machine tool or system, it is wise to invest time in preventative maintenance as prescribed by the manufacturer. With proper care, it is easy to keep machine tools functioning at their maximum performance level – saving shops time and money in the long run.

Posted: September 5, 2014

Most fabricators are familiar with the water cooling circuits used to cool the modern machinery found in their shop. As these industrial machines perform their intended processes, water circulates to remove heat from the system. The cooling process, therefore, serves an essential role for laser cutting systems, punching machines, and other standard equipment used for metal processing. Although shops usually realize they must change the water in the cooling circuit regularly, they are often unaware of certain factors that will influence the process and ultimately, the machine’s performance.

THE BASICS

The water in the machine’s cooling circuit should be changed once a year as a standard maintenance procedure. To guarantee the best results, start by flushing the system with a stabilizer or cleanser specifically designed for the task. Rinse the tank before adding new, deionized (DI) water and the appropriate chemical kit.

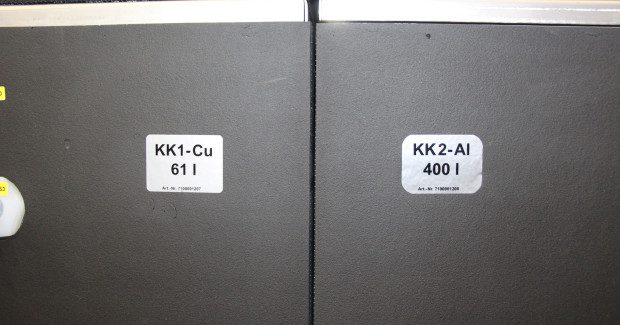

When emptying and refilling the water, make sure the pump and hose are dedicated to the job since any device that previously moved oils or similar liquids will inadvertently contaminate the DI water. It is also important to note whether the water circuit in your machine is made of copper or aluminum, since the material will impact the amount of DI water and the chemicals that should be used when refilling the tank. The material type is usually marked on the side of the tank.

NOT ALL WATER IS CREATED EQUAL

When changing the water in the cooling system, it is essential to use deionized water, also known as demineralized (DM) water. Deionization is a multi-step chemical process whereby almost all of the water’s mineral ions such as sodium, iron and copper, as well as chloride and sulfate are removed. The high purity water produced is considered to be more pure than distilled water, which is purified through a boiling, evaporation and condensation process.

Depending on the supply restrictions and demand requirements of the shop, manufacturers might consider renting a service deionization system. By connecting these portable tanks directly to the tap water supply in a facility, water treatment can be conducted onsite and at the shop’s leisure. Producing highly pure water on demand is also an advantage for any facility located in a remote area or where accessibility to DI water suppliers is limited.

Cooling systems require deionized water because of its high purity and low conductivity. The water must be extremely pure to keep the water circuit contaminant free and prevent damaging build up within the system. It also facilitates the proper flow of water to the optics and will prevent any distortion that would result due to overheating. High purity water keeps the focusing valves clean and functioning correctly.

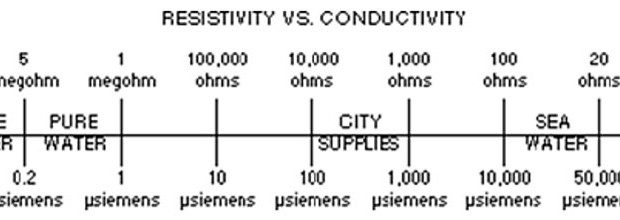

The conductivity of DI water is also a specific concern in the cooling system. As the water travels through the RF circuit, it becomes part of it. If its conductivity is too high, the RF cabinet will begin to malfunction, potentially causing damage to the system.

DI WATER MANAGEMENT

Fabricators who do not generate deionized water as needed must remember DI water is corrosive and must be stored appropriately. Glass is a good choice of material for this, as are some plastics. However, some plastic containers, such as those made of PVC, contain chemicals that may leach into the water and should be avoided. If the container is made of a ceramic or a metal it must be lined with tin to protect the purity of the water. Further protect deionized water from outside contaminants, such as bacteria and microbes, by keeping the container tightly sealed with a plug that will not react with the water.

If the water has been stored, it is best to test the micro-siemen level with a conductivity meter before adding it to the cooling circuit. Every machine has a set tolerance for conductivity, and over time, the conductivity of the water will change.

Fabricators should always be aware of the machine’s specific requirements and dispose of any water that falls outside of this tolerance. When doing this, one should remember that although the DI cooling water remains visually clear, chemicals have been introduced to the water and it should be disposed of as waste. Take care to review the MSDS sheet with the local environmental department. These experts will advise you of the proper handling and disposal of coolant water.

COMPLETING THE PROCESS

While changing the DI water in the cooling circuit, it is also best to address two additional maintenance check points that affect the chilling unit’s performance.

First, visually inspect the outside cabinet filter mats and assess their condition. As dirt accumulates on the mats, it will impede the flow of air to the system, influencing the temperature of the water inside the tank and the overall performance of the machine. It is important to change these filter mats regularly. Second, fabricators should replace the micron filters in the water circuit semi-annually. This helps to maintain the purity and conductivity of the water in the tank.

Regardless of the machine or system, it is wise to invest time in preventative maintenance as prescribed by the machine tool manufacturer. With proper care, it is easy to keep machines functioning at their maximum performance level – saving fabricators time and money in the long run.