Going in Forward and Reverse

The entire machining process chain can now be run in art-to-part simulation, with feedback and corrections made from end-to-end.

Posted: September 6, 2014

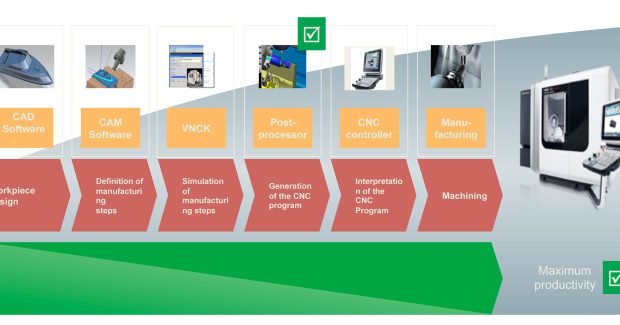

Your designers or your customers start with a CAD file that represents the “best effort” math model for the part. Your programmers take it to 2-1/2 or solid 3D imaging inside a CAM program. You post and verify a fully simulated machining or fabrication process cycle within a “virtual machine” that is offline. You work with your tool suppliers’ libraries of performance properties to capture all relevant data on material composition, toolholder specifications and applications, collision avoidance, even spindle interface. You create the part with full recording and tracking of the cutting characteristics, machine dynamics, thermal expansion, part articulation sequences and, of course, actual run time to finish.

Sound incredible? Keep reading, because it gets even better.

You have the virtual finished part and you can now run it through the coordinate measuring machine for verification of all dimensions and surface quality, comparing every aspect of the geometry against your original. The CMM detects an inaccuracy and can “push back” the changes required into the virtual machine, which then transfers the change information back into the CAM program for alterations and, finally, all the way back into the CAD model for part design modifications.

If this is beginning to sound like a rugby game, you’re only half right, because the same team is going in both directions – namely, yours!

One of the coolest innovations in CNC technology has been this evolution of a forward-reverse data transfer capability. It has resulted from advancements in the virtual NC kernel (VNCK) in the CNC, which today not only creates the simulation model for machining, but also has the ability to redirect data from the quality checking and data transfer software on a CMM to “reverse” the processing of the part back to the design stage. This feature allows modifications for both product performance and machining or fabricating process improvements in your production cycle.

In other words, with this new VNCK feature you get verification of both the part quality and the manufacturing integrity, plus the enhanced ability to make changes in both directions of the process chain, all in a virtual but very true-to-reality environment. In this way you can realize substantial increases in production, whether in a job shop floor environment or the largest production department out there. The data accumulated in this entire process chain operation are accessible for PLM utilization as well, a significant upside for production planners and others on your team.

A lot of us in my generation were long skeptical of “simulation” as a viable part of the shop environment, but it has become exactly that. It saves large amounts of time and money since you’re running the programs entirely offline, an obvious advantage with million-dollar machining centers. Moreover, you’re not only able to see problems occurring in the tooling, toolholder, workholding, fixturing, machine kinematics and thermal characteristics of the part over a long cycle and more, because you can then review the impact of each of those difficulties over the entire process, making changes back as far as the actual part design, when necessary.

And you do all of this long before the first chip is cut or the first weld bead is laid.

As an added benefit, the security of this entire process can be insured in today’s manufacturing environment, where data transfer can be carefully planned, monitored and limited to only those with a need-to-know status. You can share the entire process chain, or only portions thereof, with key people on your team, your customer’s team, even the machine builder and the CNC supplier, all through firewall-protected, one-way or read-only channels. This protects the integrity of your process, the confidentiality of your customer relationships and the access to data at all levels and to all degrees.

Since the adjustments to the production cycle are being made offline, even your maintenance personnel will see reductions in their troubleshooting as the percentage of good first parts and consistent quality over long runs improve. The bottom line is this: whichever direction you use this exciting new CNC development, it will benefit your organization, in forward and/or reverse.